DTC P0463 FUEL LEVEL SENSOR CIRCUIT HIGH INPUT

| DTC P0463 FUEL LEVEL SENSOR CIRCUIT HIGH INPUT |

DTC DETECTING CONDITION:

| • |

Two consecutive driving cycles with fault

|

|

| • |

GENERAL DESCRIPTION

|

|

| Important | ||

|

After repair

or replacement of faulty parts, conduct Clear Memory Mode

|

||

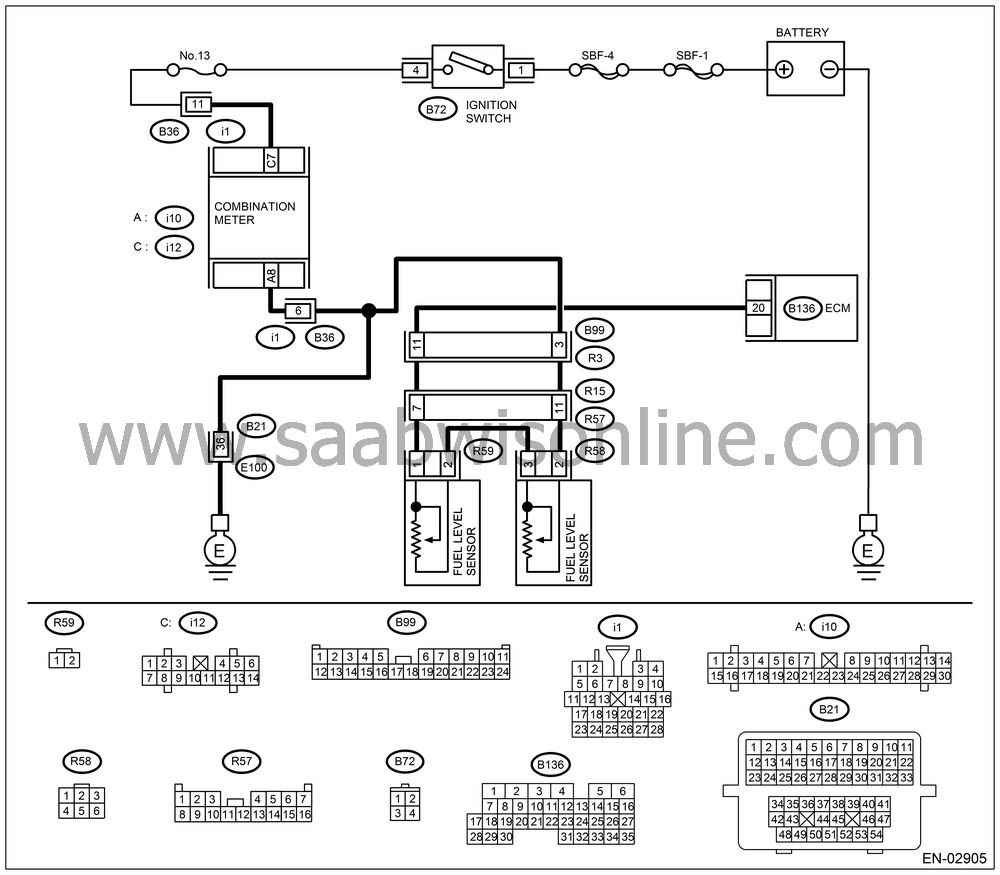

WIRING DIAGRAM:

CHECK SPEEDOMETER AND TACHOMETER OPERATION IN COMBINATION METER.

Does the speedometer and tachometer operate normally?

| Yes |

| No |

Repair or replace the combination meter.

CHECK INPUT SIGNAL FOR ECM.

Turn the ignition switch to ON. (Engine OFF)Measure the voltage between ECM connector and chassis ground.

Connector & terminal

(B136) No. 20 (+) — Chassis ground (−):

Is the voltage more than 4.75 V?

| Yes |

| No |

| • |

Even if malfunction indicator

light lights up, the circuit has returned to a normal condition

at this time. A temporary poor contact of the connector may be the cause.

|

|

| • |

|

|||||||||||||

CHECK INPUT VOLTAGE OF ECM.

Turn the ignition switch to OFF.Disconnect the combination meter connector (i12) and ECM connector.

Turn the ignition switch to ON.

Measure the voltage of harness between ECM and chassis ground.

Connector & terminal

(B136) No. 20 (+) — Chassis ground (−):

Is the voltage more than 4.75 V?

| Yes |

| No |

Repair battery short circuit between ECM and combination meter connector.

CHECK HARNESS BETWEEN ECM AND FUEL TANK CORD.

Turn the ignition switch to OFF.Separate fuel tank cord connector (R57) and rear wiring harness connector (R15).

Measure the resistance between ECM and fuel tank cord.

Connector & terminal

(B136) No. 20 — (R15) No. 7:

Is the resistance less than 5 Ω?

| Yes |

| No |

Repair open circuit between ECM and fuel tank cord.

CHECK HARNESS BETWEEN FUEL TANK CORD AND CHASSIS GROUND.

Measure the resistance between fuel tank cord and chassis ground.Connector & terminal

(R15) No. 11 — Chassis ground:

Is the resistance less than 5 Ω?

| Yes |

| No |

| • |

Repair open circuit between

fuel tank cord and chassis ground.

|

|

| • |

|

||||||||||

CHECK FUEL TANK CORD.

Disconnect the connector from fuel level sensor.Measure the resistance between fuel level sensor and coupling connector.

Connector & terminal

(R57) No. 11 — (R58) No. 2:

Is the resistance less than 10 Ω?

| Yes |

| No |

Repair open circuit between coupling connector and fuel level sensor.

CHECK FUEL TANK CORD.

Disconnect the connector from fuel sub level sensor.Measure the resistance between fuel level sensor and fuel sub level sensor.

Connector & terminal

(R58) No. 3 — (R59) No. 2:

Is the resistance less than 10 Ω?

| Yes |

| No |

Repair open circuit between fuel level sensor and fuel sub level sensor.

CHECK FUEL TANK CORD.

Measure the resistance between fuel level sensor and coupling connector.Connector & terminal

(R57) No. 7 — (R59) No. 1:

Is the resistance less than 10 Ω?

| Yes |

| No |

Repair open circuit between coupling connector and fuel level sensor.

CHECK FUEL LEVEL SENSOR.

Remove the fuel pump assembly.

While moving the fuel level sensor float up and down, measure resistance between fuel level sensor terminals.

Terminals

No. 3 — No. 2:

Is the resistance more than 54.5 Ω?

| Yes |

Replace the fuel level sensor.

| No |

CHECK FUEL SUB LEVEL SENSOR.

Remove the fuel sub level sensor.

While moving the fuel sub level sensor float up and down, measure resistance between fuel sub level sensor terminals.

Terminals

No. 1 — No. 2:

Is the resistance more than 41.5 Ω?

| Yes |

Replace the fuel sub level sensor.

| No |

Replace the combination meter.