DTC P2096 POST CATALYST FUEL TRIM SYSTEM TOO LEAN BANK 1

|

|

DTC P2096 POST CATALYST FUEL TRIM SYSTEM

TOO LEAN BANK 1

|

CHECK ANY OTHER DTC ON DISPLAY.

Is any other

DTC displayed?

|

•

|

Check DTC using “List

of Diagnostic Trouble Code (DTC)”.

|

|

•

|

|

Note

|

|

In this case, it is not necessary

to inspect DTC P0137.

|

|

CHECK REAR OXYGEN SENSOR DATA.

Warm-up the engine until engine coolant temperature

is above 70°C (158°F), and keep the engine speed

at 5,000 rpm.

Read the data of rear oxygen sensor signal using Vehicle

Diagnostic Interface or OBD-II general scan tool.

|

Note

|

|

•

|

Vehicle Diagnostic Interface

For detailed operation procedure, refer to the “READ

CURRENT DATA SHOWN ON DISPLAY FOR ENGINE”.

|

|

•

|

OBD-II general scan tool

For detailed operation procedures, refer to the OBD-II General

Scan Tool Instruction Manual.

|

Is the voltage 490 mV?

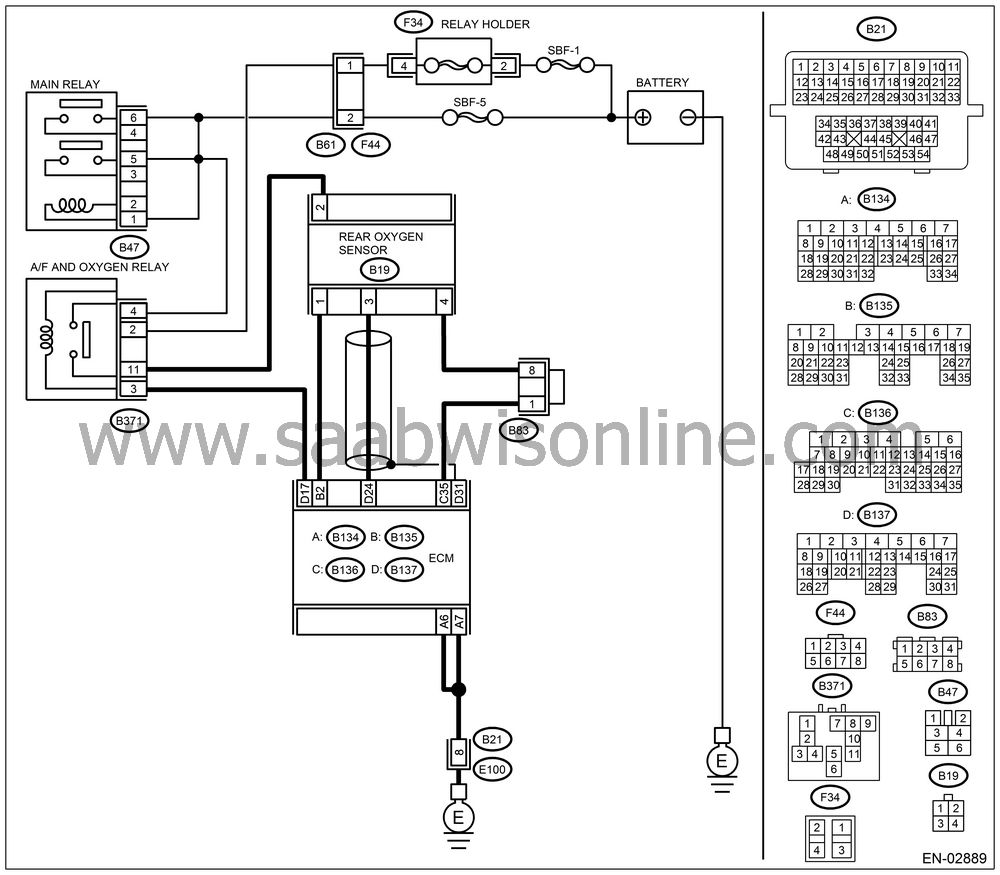

CHECK HARNESS BETWEEN ECM AND REAR OXYGEN SENSOR CONNECTOR.

Turn the ignition switch to OFF.

Disconnect the connectors from ECM and rear oxygen

sensor.

Measure the resistance of harness between ECM and rear

oxygen sensor connector.

Connector & terminal

(B137) No. 24 — (B19) No. 3:

(B136) No. C35 — (B19) No. 4:

Is the resistance more than 3 Ω?

Repair open circuit in harness between

ECM and rear oxygen sensor connector.

CHECK HARNESS BETWEEN REAR OXYGEN SENSOR AND ECM CONNECTOR.

Turn the ignition switch to OFF.

Disconnect the connector from rear oxygen sensor.

Turn the ignition switch to ON.

Measure the voltage between rear oxygen sensor harness

connector and engine ground or chassis ground.

Connector & terminal

(B19) No. 3 (+) — Engine ground (−):

Is the voltage 0.2 — 0.5 V?

Replace the rear oxygen sensor.

|

•

|

Repair harness and connector.

|

|

•

|

|

Note

|

|

In this case, repair the following:

|

|

•

|

Open circuit

in harness between rear oxygen sensor and ECM connector

|

|

•

|

Poor contact in rear oxygen sensor connector

|

|

•

|

Poor contact in ECM connector

|

|

CHECK EXHAUST SYSTEM.

Check exhaust system parts.

|

Note

|

|

Check the following items.

|

|

•

|

Loose

installation of portions

|

|

•

|

Damage (crack, hole etc.) of parts

|

|

•

|

Looseness and ill fitting of parts between front oxygen

(A/F) sensor and rear oxygen sensor

|

Is there a fault in exhaust system?

Repair or replace faulty parts.

CHECK AIR INTAKE SYSTEM.

Are there holes,

loose bolts or disconnection of hose on air intake system?

Repair air intake system.

CHECK PURGE CONTROL SOLENOID VALVE OR PRESSURE CONTROL SOLENOID

VALVE.

Is the purge control solenoid valve or pressure

control solenoid valve stuck?

Replace the purge control solenoid valve

or pressure control solenoid valve.

CHECK FUEL PRESSURE.

Warning

Warning

|

|

•

|

Place “NO FIRE” signs

near the working area.

|

|

•

|

Be careful not to spill fuel on the floor.

|

|

|

|

|

|

Release fuel pressure.

Connect the connector to fuel pump relay.

Disconnect the fuel delivery hose from fuel filter,

and connect fuel pressure gauge.

Install the fuel filler cap.

Start the engine and idle while gear position is neutral.

Measure the fuel pressure while disconnecting pressure

regulator vacuum hose from intake manifold.

Warning

Warning

|

|

Before removing the fuel pressure

gauge, release fuel pressure.

|

|

|

|

|

|

|

Note

|

|

If fuel pressure does not increase,

squeeze fuel return hose 2 to 3 times, then measure fuel pressure

again.

|

Is the fuel pressure

284 — 314 kPa (2.9 — 3.2 kg/cm

2

,

41 — 46 psi)?

|

•

|

Repair the following items.

|

|

|

•

|

Clogged fuel return line or bent hose

|

|

|

•

|

Improper fuel pump discharge

|

|

|

•

|

Clogged fuel supply line

|

CHECK FUEL PRESSURE.

After connecting the pressure regulator vacuum hose, measure

fuel pressure.

Warning

Warning

|

|

Before removing the fuel pressure

gauge, release fuel pressure.

|

|

|

|

|

|

|

Note

|

|

•

|

If fuel pressure does not increase, squeeze fuel return

hose 2 to 3 times, then measure fuel pressure again.

|

|

•

|

If out of specification as measured at this step, check

or replace pressure regulator and pressure regulator vacuum hose.

|

Is the fuel pressure 206 — 235 kPa (2.1 — 2.4

kg/cm

2

, 30 — 34 psi)?

|

•

|

Repair the following items.

|

|

|

•

|

Faulty pressure regulator

|

|

|

•

|

Clogged fuel return line or bent hose

|

|

|

•

|

Faulty pressure regulator

|

|

|

•

|

Improper fuel pump discharge

|

|

|

•

|

Clogged fuel supply line

|

CHECK ENGINE COOLANT TEMPERATURE SENSOR.

Start the engine and warm-up completely.

Read the data of engine coolant temperature sensor

signal using Vehicle Diagnostic Interface

or OBD-II general scan tool.

|

Note

|

|

•

|

Vehicle Diagnostic Interface

For detailed operation procedure, refer to the “READ

CURRENT DATA FOR ENGINE”.

|

|

•

|

OBD-II general scan tool

For detailed operation procedures, refer to the OBD-II General

Scan Tool Instruction Manual.

|

Is the engine coolant temperature 70 — 100°C

(158 — 212°F)?

Replace the engine coolant temperature

sensor.

CHECK PRESSURE SENSOR SIGNAL.

Start the engine and warm-up engine until coolant temperature

is greater than 60°C (140°F).

Place the select lever in “N” or “P” range.

Turn the A/C switch to OFF.

Turn all accessory switches to OFF.

Read the data of pressure sensor signal using Vehicle

Diagnostic Interface or OBD-II general scan tool.

|

Note

|

|

•

|

Vehicle Diagnostic Interface

For detailed operation procedure, refer to the “READ

CURRENT DATA FOR ENGINE”.

|

|

•

|

OBD-II general scan tool

For detailed operation procedures, refer to the OBD-II General

Scan Tool Instruction Manual.

|

Idling: Is the measured value 24.0 — 41.3 kPa

(180 — 310 mmHg, 7.09 — 12.20 inHg), Ignition

ON: Is the measured value 73.3 — 106.6 kPa (550 — 800

mmHg, 21.65 — 31.50 inHg)?

Contact Service Center.

Replace the Pressure sensor.

Warning

Warning