DTC P2101 THROTTLE ACTUATOR CONTROL MOTOR CIRCUIT RANGE/PERFORMANCE

| DTC P2101 THROTTLE ACTUATOR CONTROL MOTOR CIRCUIT RANGE/PERFORMANCE |

DTC DETECTING CONDITION:

| • |

Immediately at fault recognition

|

|

| • |

GENERAL DESCRIPTION

,

,

and

and

|

|

TROUBLE SYMPTOM:

| • |

Erroneous idling

|

|

| • |

Poor driving performance

|

|

| • |

Engine stalls.

|

|

| Important | ||

|

After repair

or replacement of faulty parts, conduct Clear Memory Mode

|

||

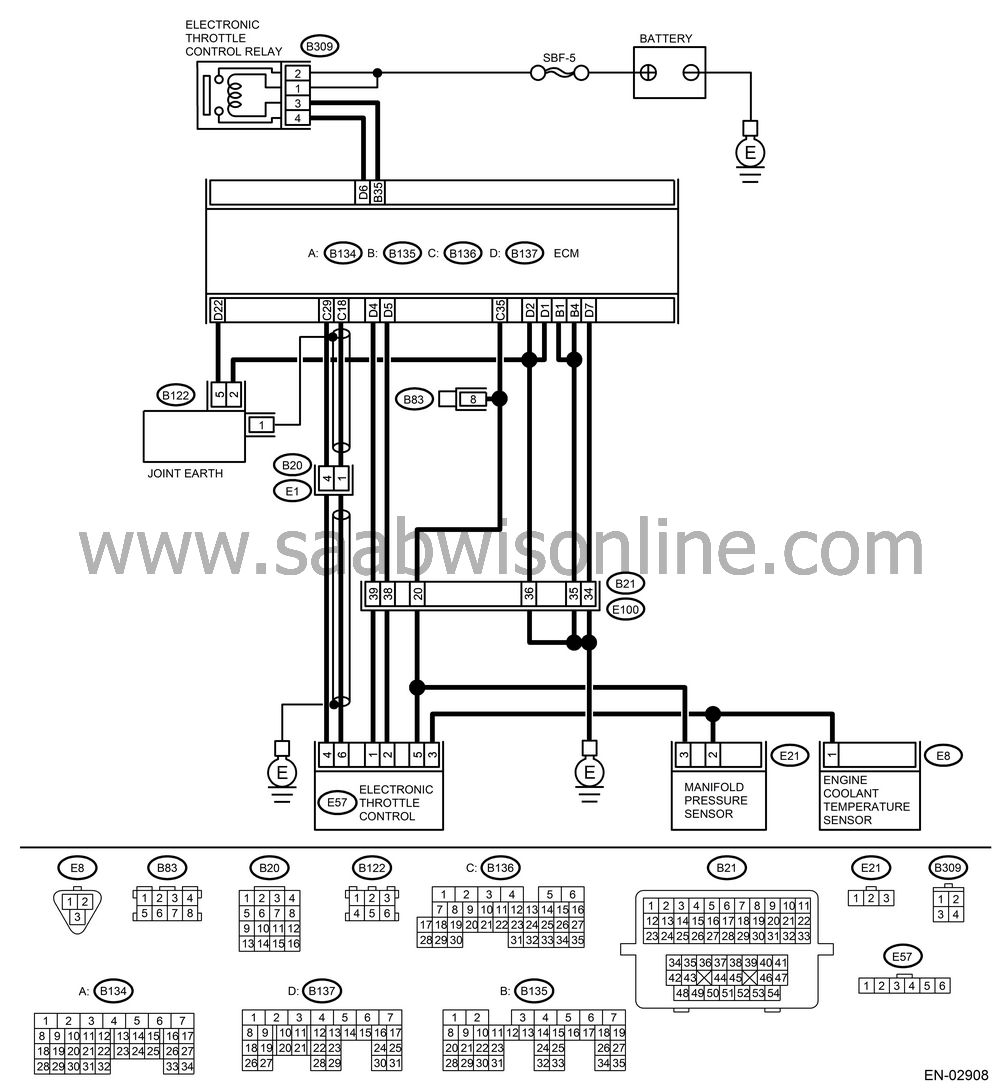

WIRING DIAGRAM:

CHECK ELECTRONIC THROTTLE CONTROL RELAY.

Turn the ignition switch to OFF.Remove the electronic throttle control relay.

Connect the battery to electronic throttle control relay terminal No. 1 and No. 3.

Measure the resistance between electronic throttle control relay terminals.

Terminals

No. 2 — No. 4:

Is the resistance less than 1 Ω?

| Yes |

| No |

Replace the electronic throttle control relay.

CHECK POWER SUPPLY TO ELECTRONIC THROTTLE CONTROL RELAY.

Measure the voltage between electronic throttle control relay connector and chassis ground.Connector & terminal

(B309) No. 1 (+) — Chassis ground (−):

(B309) No. 2 (+) — Chassis ground (−):

Is the voltage more than 5 V?

| Yes |

| No |

Repair the open power supply circuit or ground short.

CHECK HARNESS BETWEEN ECM AND ELECTRONIC THROTTLE CONTROL.

Disconnect the connector from ECM.Turn the ignition switch to ON.

Measure the voltage between electronic throttle control relay connector and chassis ground.

Connector & terminal

(B309) No. 3 (+) — Chassis ground (−):

Is the voltage less than 5 V?

| Yes |

| No |

Repair short of the power supply circuit between ECM and electronic throttle control.

CHECK HARNESS BETWEEN ECM AND ELECTRONIC THROTTLE CONTROL.

Turn the ignition switch to OFF.Measure the resistance between electronic throttle control electronic throttle control relay connector and chassis ground.

Connector & terminal

(B309) No. 3 — Chassis ground:

(B309) No. 4 — Chassis ground:

Is the resistance more than 1 MΩ?

| Yes |

| No |

Repair the ground short of harness between ECM and electronic throttle control relay.

CHECK HARNESS BETWEEN ECM AND ELECTRONIC THROTTLE CONTROL RELAY.

Turn the ignition switch to OFF.Measure the resistance between electronic throttle control connector and electronic throttle control relay connector.

Connector & terminal

(B135) No. 35 — (B309) No. 3:

(B137) No. 6 — (B309) No. 4:

Is the resistance less than 1 Ω?

| Yes |

| No |

Repair the open circuit of harness between ECM and electronic throttle control relay.

CHECK OUTPUT VOLTAGE OF SENSOR.

Connect all the connectors.Turn the ignition switch to ON.

Read the data of main throttle sensor signal, using the Vehicle Diagnostic Interface.

Is the voltage more than 0.4 V?

| Yes |

| No |

CHECK OUTPUT VOLTAGE OF SENSOR.

Connect all the connectors.Turn the ignition switch to ON.

Read the data of sub throttle sensor signal, using the Vehicle Diagnostic Interface.

Is the voltage more than 0.8 V?

| Yes |

| No |

CHECK POOR CONTACT.

Check poor contact between ECM connector and electronic throttle control connector.Is there poor contact between ECM connector and electronic throttle control connector?

| Yes |

Repair the poor contact.

| No |

CHECK HARNESS BETWEEN ECM AND ELECTRONIC THROTTLE CONTROL.

Turn the ignition switch to OFF.Disconnect the connector from ECM.

Disconnect the connector from electronic throttle control.

Measure the resistance between ECM connector and electronic throttle control connector.

Connector & terminal

(B136) No. 18 — (E57) No. 6:

(B136) No. 29 — (E57) No. 4:

Is the resistance less than 1 Ω?

| Yes |

| No |

Repair the open harness connector.

CHECK THE HARNESS BETWEEN ECM AND ELECTRONIC THROTTLE CONTROL.

Measure the resistance between ECM connector and chassis ground.Connector & terminal

(B136) No. 18 — Chassis ground:

(B136) No. 29 — Chassis ground:

Is the resistance more than 1 MΩ?

| Yes |

| No |

Repair the ground short of harness.

CHECK POWER SUPPLY TO SENSOR.

Connect the ECM connector.Turn the ignition switch to ON.

Measure the resistance between electronic throttle control connector and engine ground.

Connector & terminal

(E57) No.5 (+) — Engine ground (−):

Is the voltage 4.5 — 5.5 V?

| Yes |

| No |

Repair the poor contact in ECM connector.

If problem persists, replace the ECM.

CHECK SHORT OF ECM.

Turn the ignition switch to OFF.Measure the resistance between electronic throttle control connector and engine ground.

Connector & terminal

(E57) No. 6 — Engine ground:

(E57) No. 4 — Engine ground:

Is the resistance more than 10 Ω?

| Yes |

| No |

Repair the poor contact in ECM connector. If problem persists, replace the ECM.

CHECK OUTPUT VOLTAGE OF SENSOR.

Connect all the connectors.Turn the ignition switch to ON.

Read the data of main throttle sensor signal, using the Vehicle Diagnostic Interface.

Is the voltage less than 4.63 V?

| Yes |

| No |

CHECK OUTPUT VOLTAGE OF SENSOR.

Read the data of sub throttle sensor signal, using the Vehicle Diagnostic Interface.Is the voltage less than 4.73 V?

| Yes |

| No |

CHECK POOR CONTACT IN CONNECTORS.

Check poor contact in connectors between ECM and electronic throttle control?Is there poor contact in connectors between ECM and electronic throttle control?

| Yes |

Repair the poor contact in connectors.

| No |

CHECK HARNESS BETWEEN ECM AND ELECTRONIC THROTTLE CONTROL.

Turn the ignition switch to OFF.Disconnect the connector from ECM.

Disconnect the connector from electronic throttle control.

Measure the resistance between ECM connector and electronic throttle control connector.

Connector & terminal

(B136) No. 18 — (E57) No. 6:

(B136) No. 29 — (E57) No. 4:

Is the resistance less than 1 Ω?

| Yes |

| No |

Repair the open harness connector.

CHECK HARNESS BETWEEN ECM AND ELECTRONIC THROTTLE CONTROL.

Connect the ECM connector.Measure the resistance between electronic throttle control connector and engine ground.

Connector & terminal

(E57) No. 3 — Engine ground:

Is the resistance less than 5 Ω?

| Yes |

| No |

Repair the poor contact in ECM connector. If problem persists, replace the ECM.

CHECK HARNESS BETWEEN ECM AND ELECTRONIC THROTTLE CONTROL.

Turn the ignition switch to ON.Measure the voltage between electronic throttle control connector and engine ground.

Connector & terminal

(E57) No. 5 (+) — Engine ground (−):

Is the voltage more than 10 V?

| Yes |

| No |

Repair the battery short of harness between ECM connector and electronic throttle control connector.

CHECK HARNESS BETWEEN ECM AND ELECTRONIC THROTTLE CONTROL.

Measure the voltage between electronic throttle control connector and engine ground.Connector & terminal

(E57) No. 6 (+) — Engine ground (−):

(E57) No. 4 (+) — Engine ground (−):

Is the voltage less than 10 V?

| Yes |

| No |

Repair the short of harness between ECM connector and electronic throttle control connector.

CHECK HARNESS BETWEEN ECM AND ELECTRONIC THROTTLE CONTROL.

Turn the ignition switch to OFF.Remove the ECM.

Measure the voltage between ECM connectors.

Connector & terminal

(B136) No. 18 — (B136) No. 35:

(B136) No. 29 — (B136) No. 35:

Is the resistance more than 1 MΩ?

| Yes |

| No |

Repair the short of sensor power supply.

CHECK OUTPUT VOLTAGE OF SENSOR.

Turn the ignition switch to OFF.Connect all the connectors except electronic throttle control replay.

Turn the ignition switch to ON.

Read the data of main throttle sensor signals, using Vehicle Diagnostic Interface.

Is the voltage 0.81 — 0.87 V?

| Yes |

| No |

Repair the poor contact in electronic throttle control connector. If problem persists, replace the electronic throttle control.

CHECK OUTPUT VOLTAGE OF SENSOR.

Read the data of sub throttle sensor signals, using Vehicle Diagnostic Interface.Is the voltage 1.64 — 1.70 V?

| Yes |

| No |

Repair the poor contact in electronic throttle control connector. If problem persists, replace the electronic throttle control.

CHECK HARNESS BETWEEN ECM AND ELECTRONIC THROTTLE CONTROL MOTOR.

Turn the ignition switch to OFF.Disconnect the connector from ECM.

Disconnect the connectors from electronic throttle control.

Measure the resistance between ECM connector and electronic throttle control connector.

Connector & terminal

(B137) No. 5 — (E57) No. 2:

(B137) No. 4 — (E57) No. 1:

Is the resistance less than 1 Ω?

| Yes |

| No |

Repair the open harness connector.

CHECK HARNESS BETWEEN ECM AND ELECTRONIC THROTTLE CONTROL MOTOR.

Connect the connectors to ECM.Turn the ignition switch to ON.

Measure the voltage between electronic throttle control connector and engine ground.

Connector & terminal

(E57) No. 2 (+) — Engine ground (−):

(E57) No. 1 (+) — Engine ground (−):

Is the voltage less than 5 V?

| Yes |

| No |

Repair the short of harness to power supply circuit between ECM and electronic throttle control.

CHECK HARNESS BETWEEN ECM AND ELECTRONIC THROTTLE CONTROL MOTOR.

Turn the ignition switch to OFF.Disconnect the connector from ECM.

Measure the resistance between electronic throttle control connector and engine ground.

Connector & terminal

(E57) No. 2 — Engine ground:

(E57) No. 1 — Engine ground:

Is the resistance more than 1 MΩ?

| Yes |

| No |

Repair the short of harness.

CHECK ELECTRONIC THROTTLE CONTROL MOTOR HARNESS.

Measure the resistance between electronic throttle control connector terminals.Connector & terminal

(E57) No. 2 — (E57) No. 1:

Is the resistance more than 1 MΩ?

| Yes |

| No |

Repair the short of harness.

CHECK ELECTRONIC THROTTLE CONTROL GROUND CIRCUIT.

Measure the resistance between ECM connector and chassis ground.Connector & terminal

(B137) No. 22 — Chassis ground:

Is the resistance less than 10 Ω?

| Yes |

| No |

Repair the open circuit harness.

CHECK ELECTRONIC THROTTLE CONTROL.

Measure the resistance between electronic throttle control terminals.Terminals

No. 1 — No. 2:

Is the resistance less than 5 Ω?

| Yes |

| No |

Replace the electronic throttle control.

CHECK ELECTRONIC THROTTLE CONTROL.

Open and close the throttle valve to its full width with finger.Does it return to specified position (3 mm (0.12 in) open from fully closed position.) when finger is released?

| Yes |

Repair the poor contact in ECM connector. If problem persists, replace the ECM.

| No |

Replace the electronic throttle control.