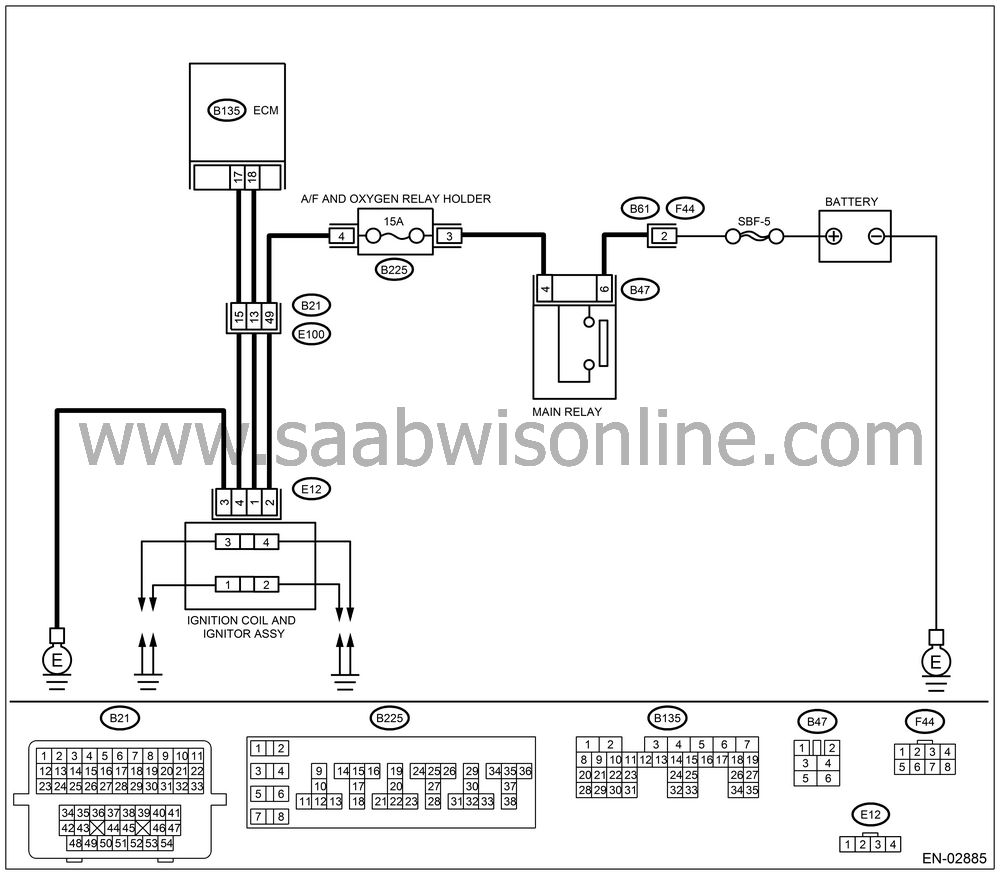

IGNITION CONTROL SYSTEM

| IGNITION CONTROL SYSTEM |

| Important | ||

|

After repair

or replacement of faulty parts, conduct Clear Memory Mode

|

||

WIRING DIAGRAM:

CHECK IGNITION SYSTEM FOR SPARKS.

Remove the plug cord cap from each spark plug.Install the new spark plug on plug cord cap.

| Important | ||

|

Do not remove the spark plug from engine. |

||

Contact the spark plug’s thread portion on engine.

While opening the throttle valve fully, crank the engine to check that spark occurs at each cylinder.

Does spark occur at each cylinder?

| Yes |

| No |

CHECK POWER SUPPLY CIRCUIT FOR IGNITION COIL AND IGNITOR ASSEMBLY.

Turn the ignition switch to OFF.Disconnect the connector from ignition coil and ignitor assembly.

Turn the ignition switch to ON.

Measure the power supply voltage between ignition coil and ignitor assembly connector and engine ground.

Connector & terminal

(E12) No. 2 (+) — Engine ground (−):

Is the voltage more than 10 V?

| Yes |

| No |

| • |

Repair harness and connector.

|

|

| • |

|

|||||||||||||

CHECK HARNESS OF IGNITION COIL AND IGNITOR ASSEMBLY GROUND CIRCUIT.

Turn the ignition switch to OFF.Measure the resistance between ignition coil and ignitor assembly connector and engine ground.

Connector & terminal

(E12) No. 3 — Engine ground:

Is the resistance less than 5 Ω?

| Yes |

| No |

| • |

Repair harness and connector.

|

|

| • |

|

||||||||||

CHECK IGNITION COIL AND IGNITOR ASSEMBLY.

Remove the spark plug cords.Measure the resistance between spark plug cord contact portions to check secondary coil.

Terminals

No. 1 — No. 2:

No. 3 — No. 4:

Is the resistance 10 — 15 kΩ?

| Yes |

| No |

Replace the ignition coil and ignitor assembly.

CHECK INPUT SIGNAL FOR IGNITION COIL AND IGNITOR ASSEMBLY.

Connect the connector to ignition coil and ignitor assembly.Check if voltage varies synchronously with engine speed when cranking, while monitoring voltage between ignition coil and ignitor assembly connector and engine ground.

Connector & terminal

(E12) No. 1 (+) — Engine ground (−):

(E12) No. 4 (+) — Engine ground (−):

Does the voltage vary more than 10 V?

| Yes |

| No |

Replace the ignition coil and ignitor assembly.

CHECK HARNESS BETWEEN ECM AND IGNITION COIL AND IGNITOR ASSEMBLY CONNECTOR.

Turn the ignition switch to OFF.Disconnect the connector from ECM.

Disconnect the connector from ignition coil and ignitor assembly.

Measure the resistance of harness between ECM and ignition coil and ignitor assembly connector.

Connector & terminal

(B135) No. 18 — (E12) No. 1:

(B135) No. 17 — (E12) No. 4:

Is the resistance less than 1 Ω?

| Yes |

| No |

| • |

Repair harness and connector.

|

|

| • |

|

|||||||||||||

CHECK HARNESS BETWEEN ECM AND IGNITION COIL AND IGNITOR ASSEMBLY CONNECTOR.

Measure the resistance of harness between ECM and engine ground.Connector & terminal:

(B135) No. 18 — Engine ground:

(B135) No. 17 — Engine ground:

Is the resistance more than 1 MΩ?

| Yes |

| No |

Repair ground short circuit in harness between ECM and ignition coil and ignitor assembly connector.

CHECK POOR CONTACT.

Check poor contact in ECM connector.Is there poor contact in ECM connector?

| Yes |

Repair poor contact in ECM connector.

| No |