INSTALLATION

| INSTALLATION |

|

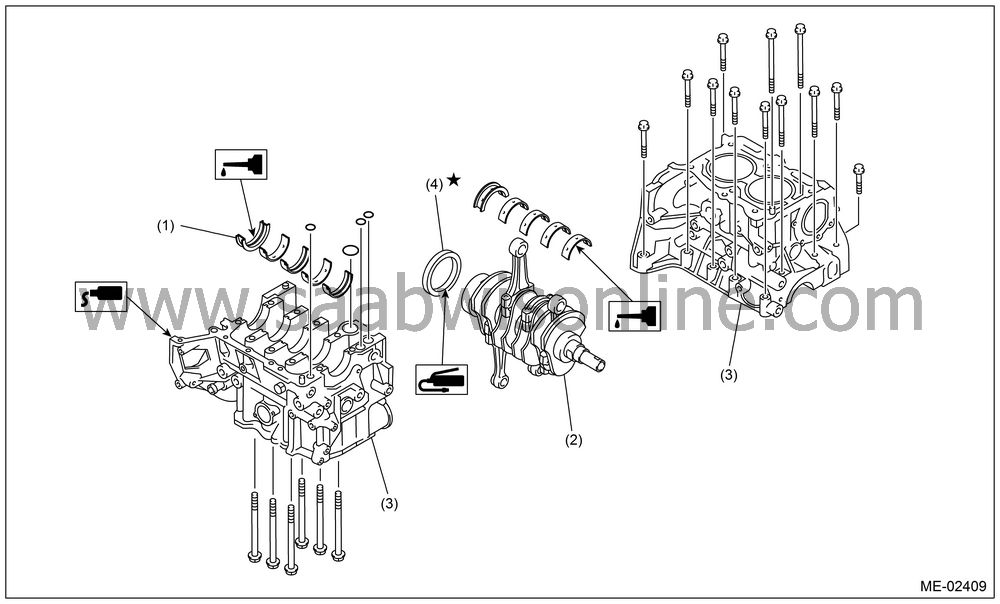

(1)

|

Crankshaft

bearing

|

(3)

|

Cylinder

block

|

(4)

|

Rear oil

seal

|

|

(2)

|

Crankshaft

|

| Note | ||

|

Remove oil on the mating surface of bearing and cylinder block before installation. Apply a coat of engine oil to crankshaft pins. |

Position the crankshaft on the #2 and #4 cylinder block.

Apply liquid gasket to the mating surface of #1 and #3 cylinder block, and position it on #2 and #4 cylinder block.

Liquid gasket:

THREE BOND 1215 (Part No. 32005013) or equivalent

| Note | ||

|

Do not allow liquid gasket to flow into O-ring grooves, oil passages, bearing grooves, etc. |

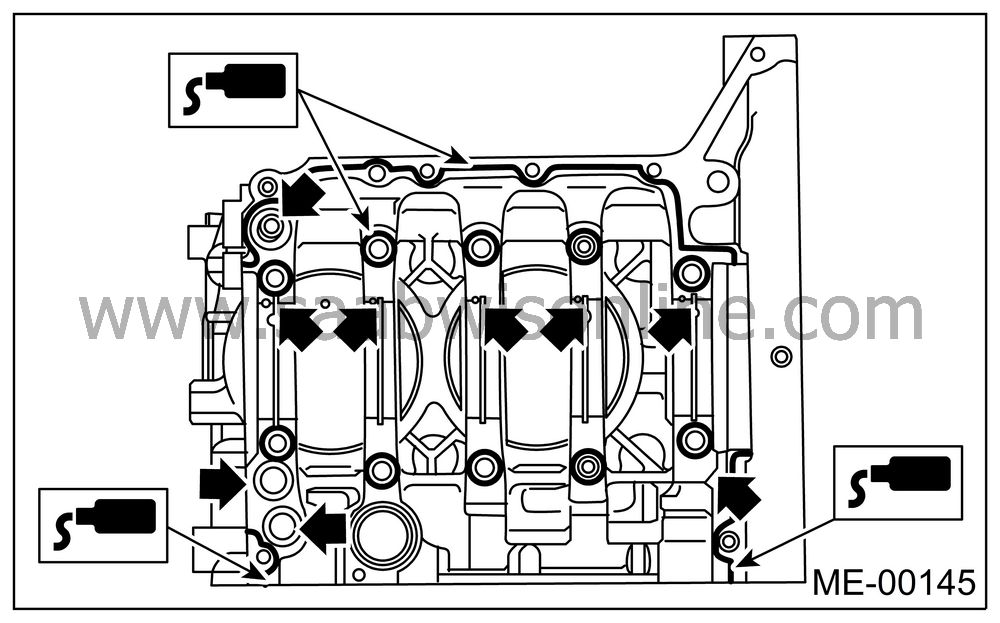

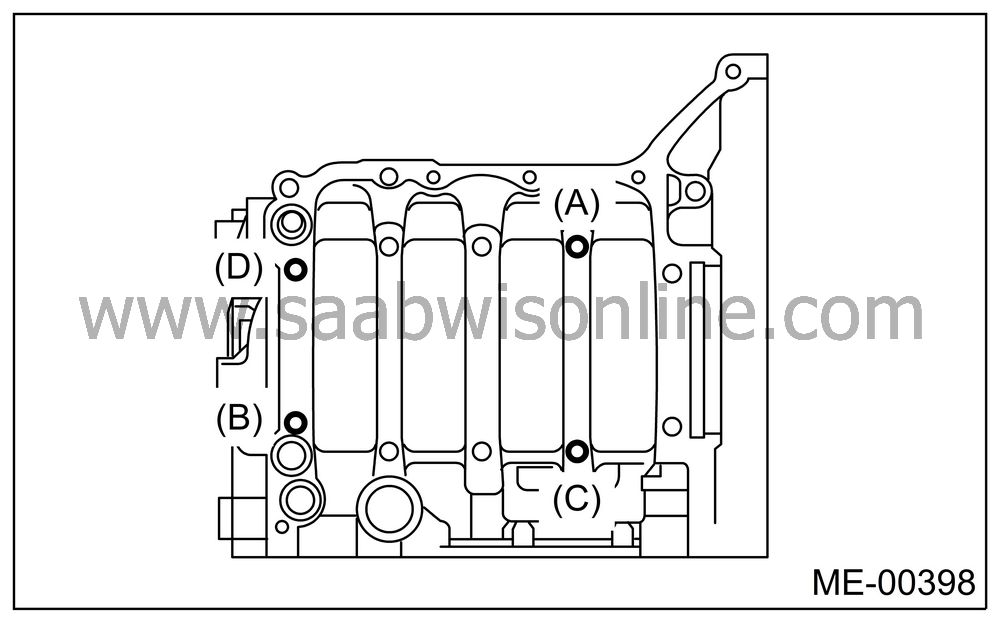

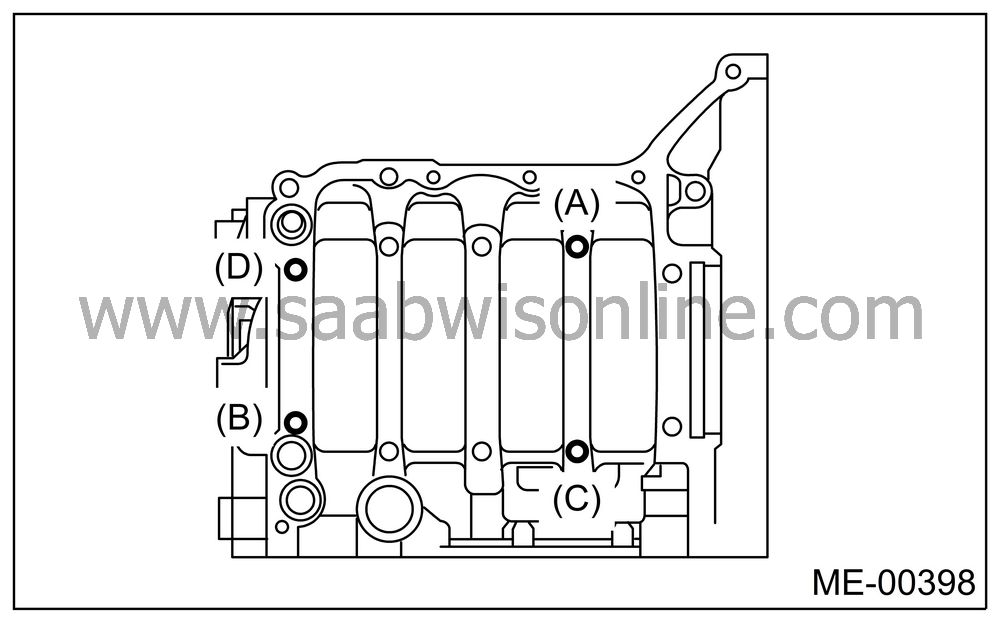

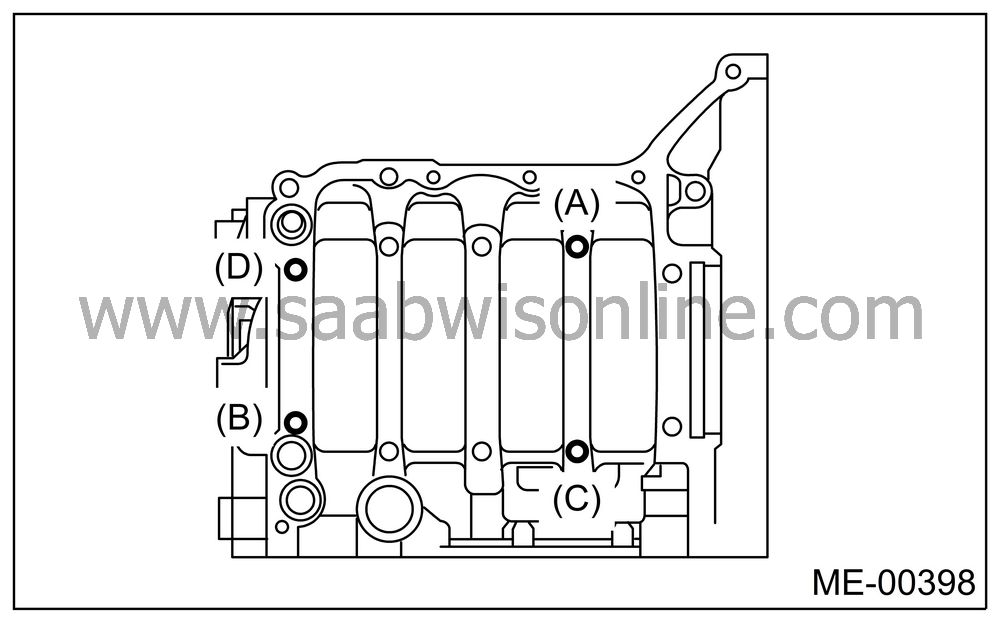

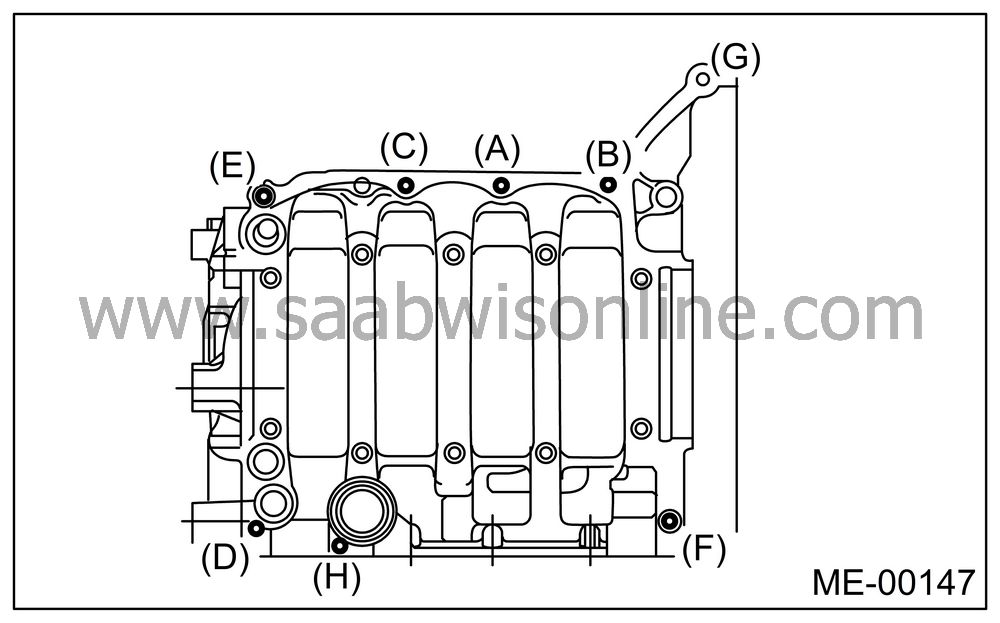

Tighten the 10 mm cylinder block connecting bolts on LH side (A — D) in alphabetical sequence.

Tightening torque:

10 Nm (1.0 kgf-m, 7.4 ft-lb)

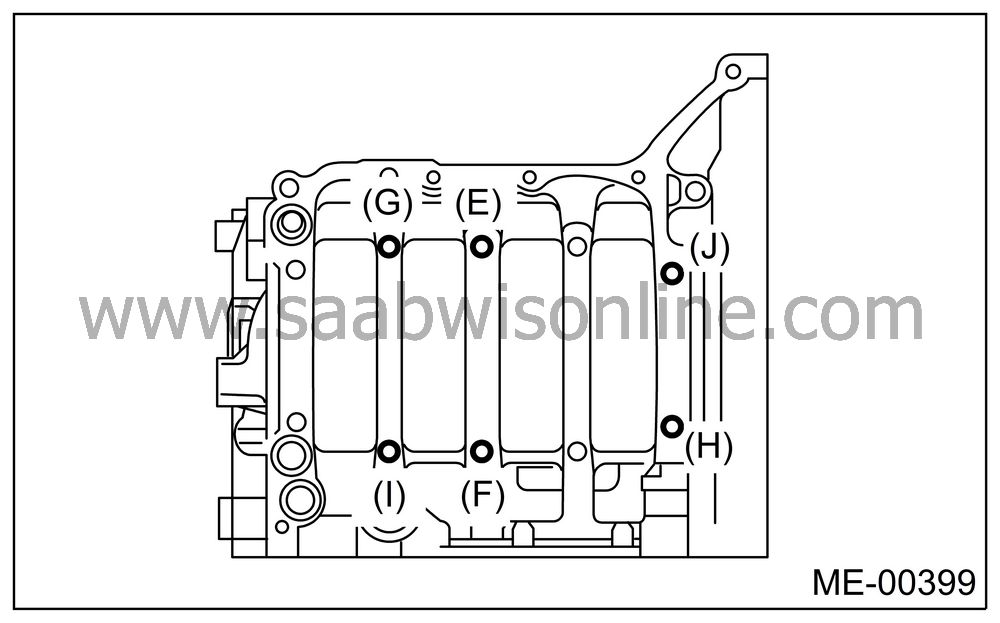

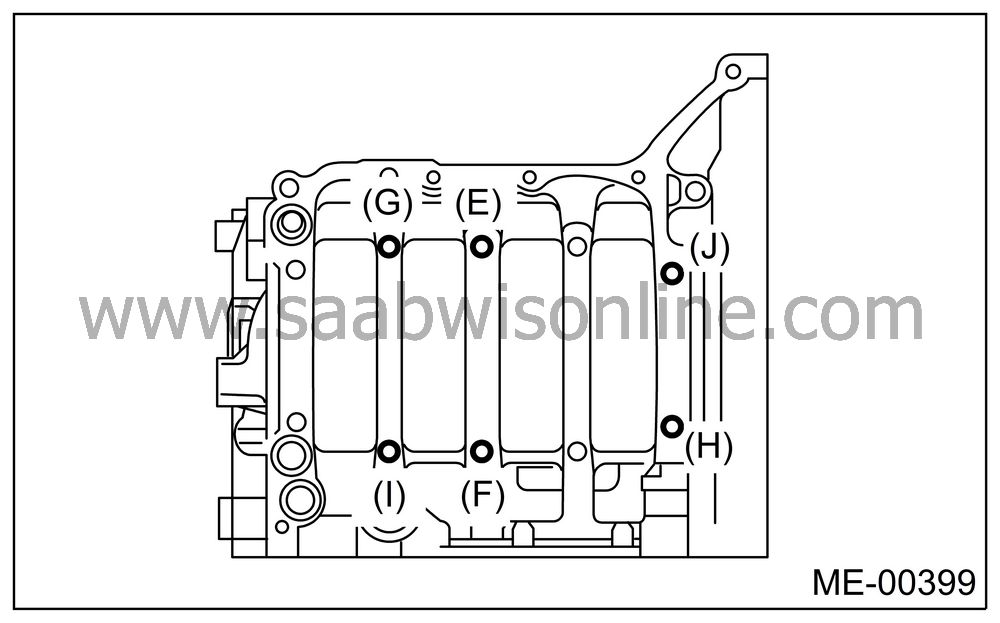

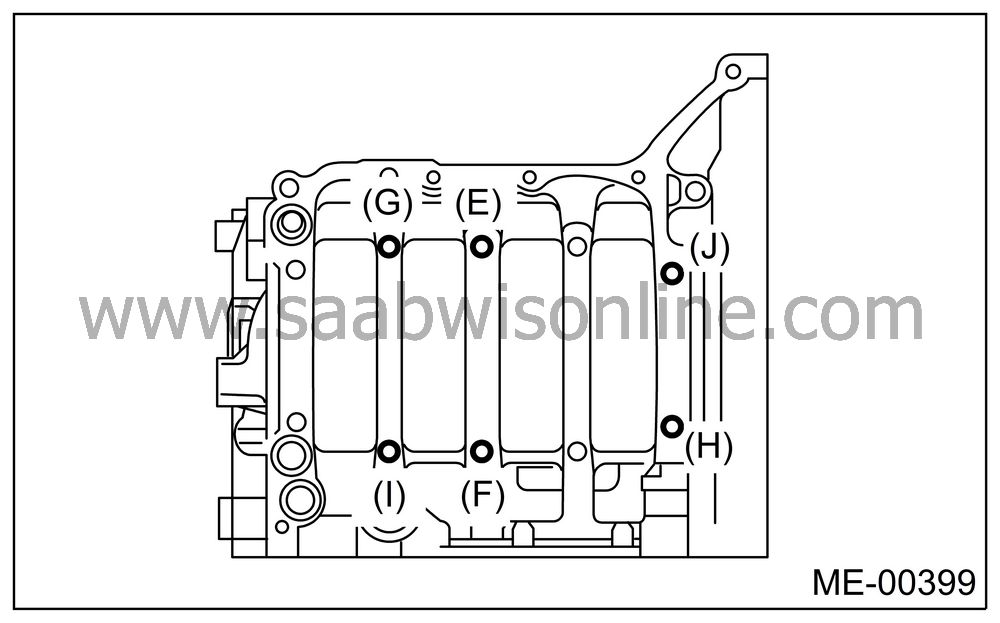

Tighten the 10 mm cylinder block connecting bolts on RH side (E — J) in alphabetical sequence.

Tightening torque:

10 Nm (1.0 kgf-m, 7.4 ft-lb)

Further tighten the LH side bolts (A — D) in alphabetical sequence.

Tightening torque:

(A), (C): 18 Nm (1.8 kgf-m, 13.3 ft-lb)

(B), (D): 18 Nm (1.8 kgf-m, 13.3 ft-lb)

Further tighten the RH side bolts (E — J) in alphabetical sequence.

Tightening torque:

(E), (F), (G), (I): 18 Nm (1.8 kgf-m, 13.3 ft-lb)

(H), (J): 18 Nm (1.8 kgf-m, 13.3 ft-lb)

Further tighten the LH side bolts (A), (C) to 90°, (B), (D) 40 Nm (4.1 kgf-m, 29.5 ft-lb) in alphabetical sequence.

Further tighten the RH side bolts (E — J) to 90° in alphabetical sequence.

Tighten the 8 mm and 6 mm cylinder block connecting bolts on LH side (A — H) in alphabetical sequence.

Tightening torque:

(A) — (G): 25 Nm (2.5 kgf-m, 18.1 ft-lb)

(H): 6.4 Nm (0.65 kgf-m, 4.7 ft-lb)

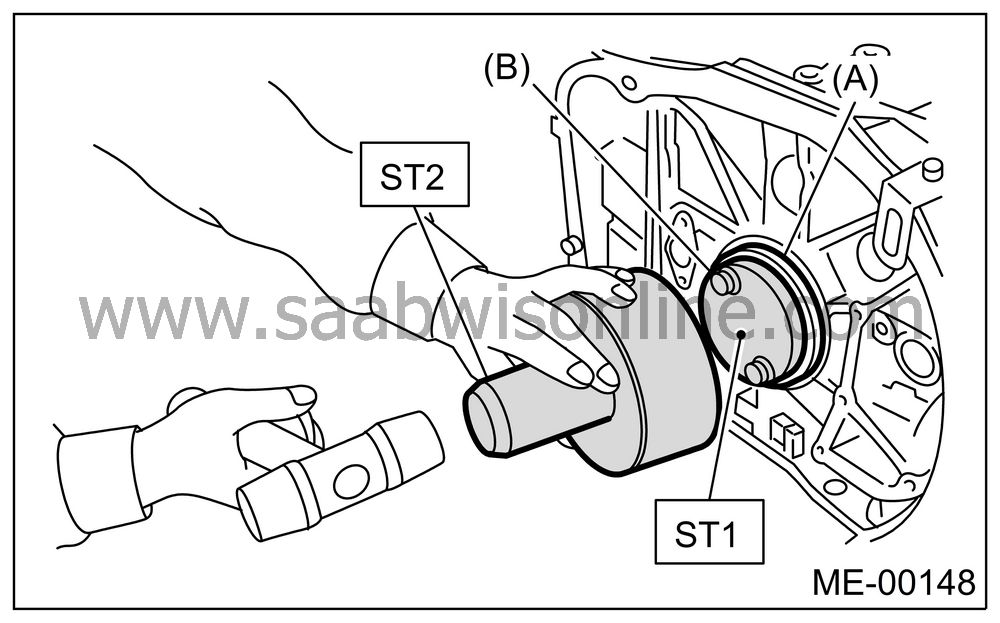

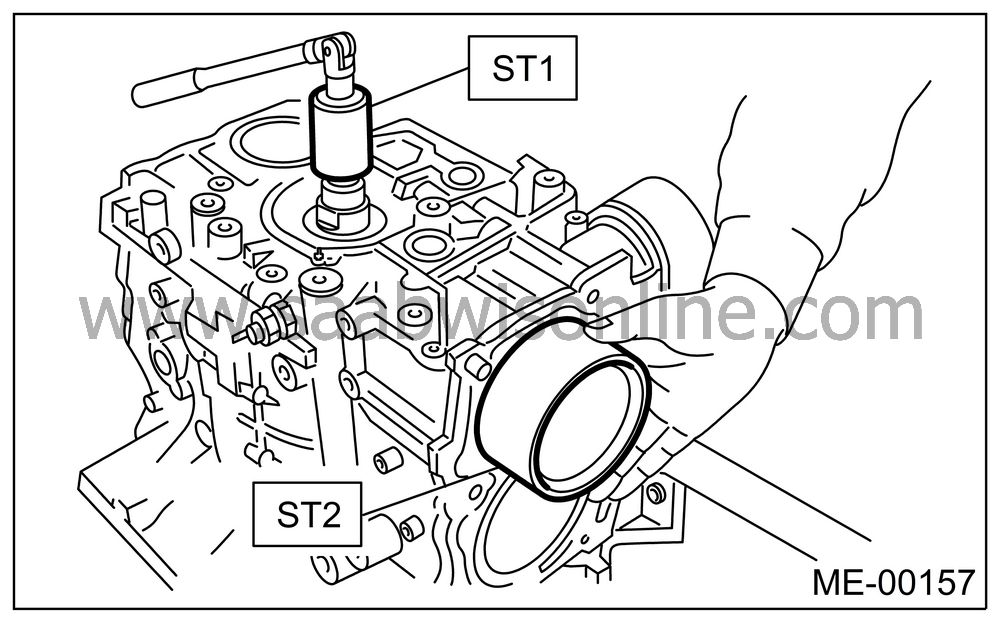

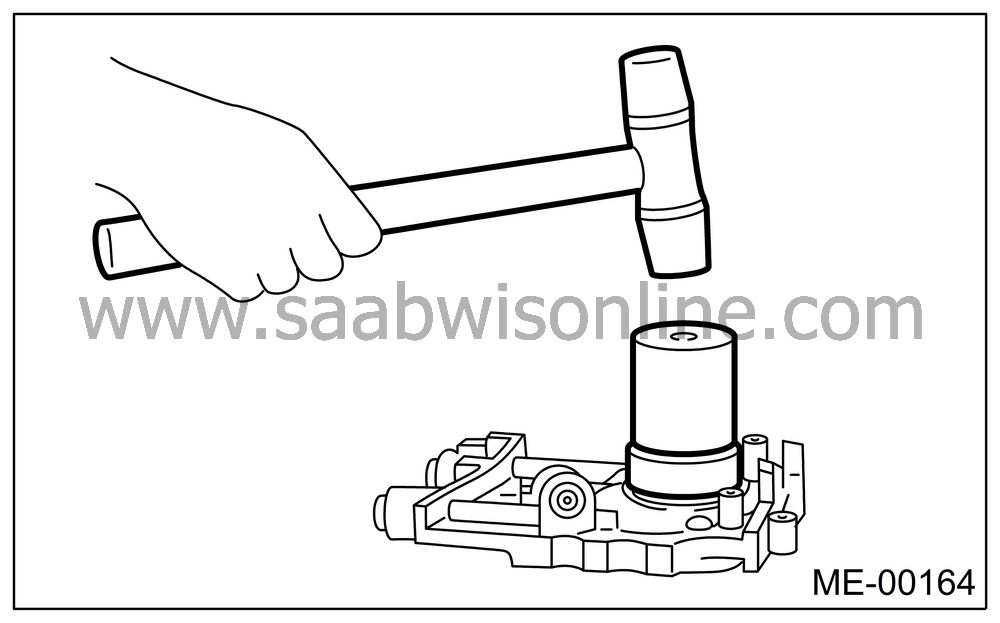

Install the rear oil seal using ST1 and ST2.

ST1 32005141 OIL SEAL GUIDE

ST2 32005136 OIL SEAL INSTALLER

|

(A)

|

Rear oil

seal

|

|

(B)

|

Flywheel

attaching bolt

|

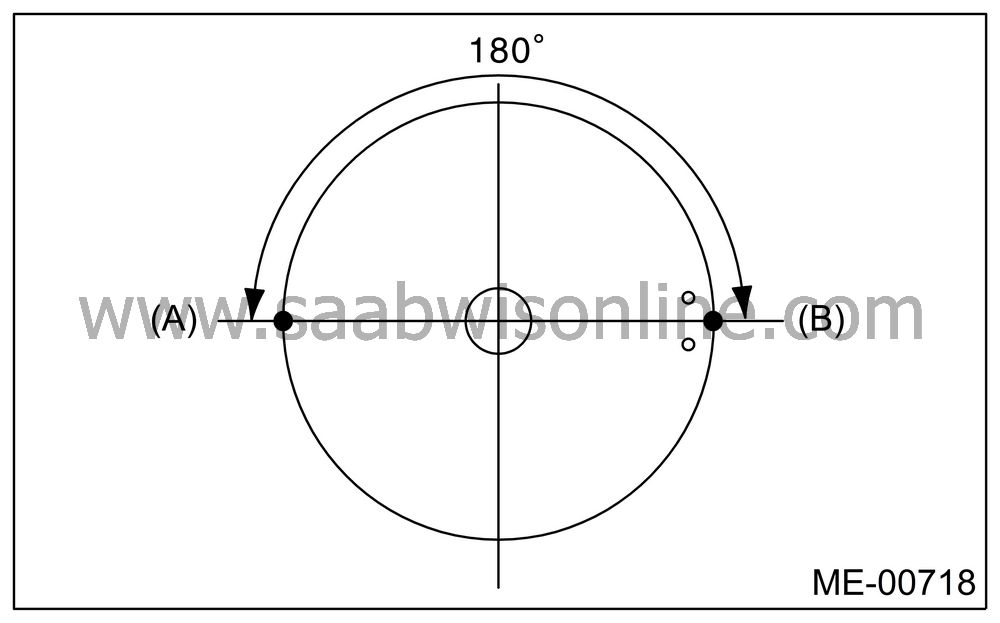

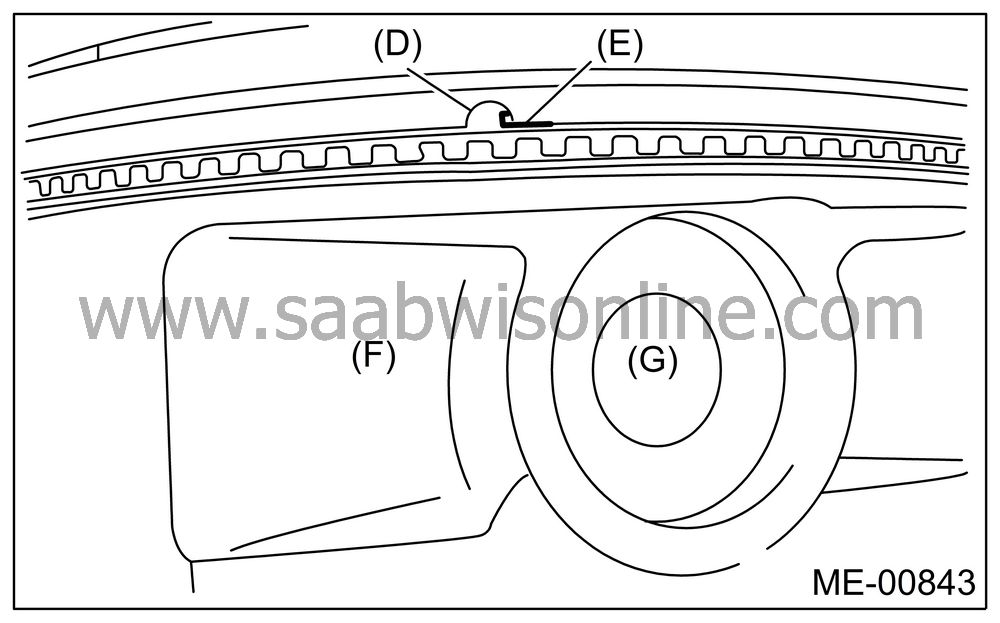

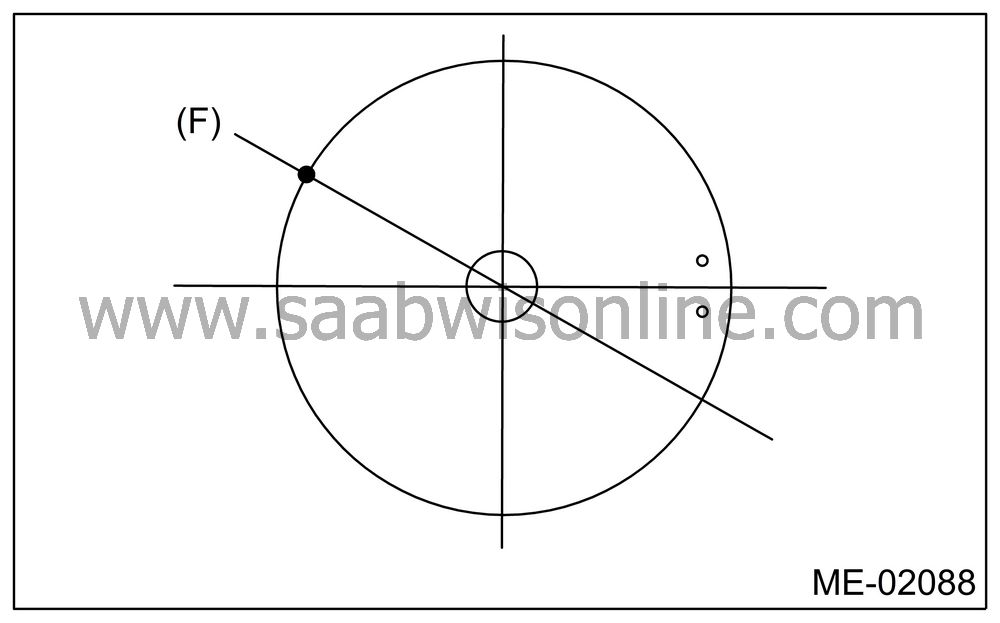

Position the top ring gap at (A) or (B) in the figure.

Position the second ring gap at 180° on the reverse side of the top ring gap.

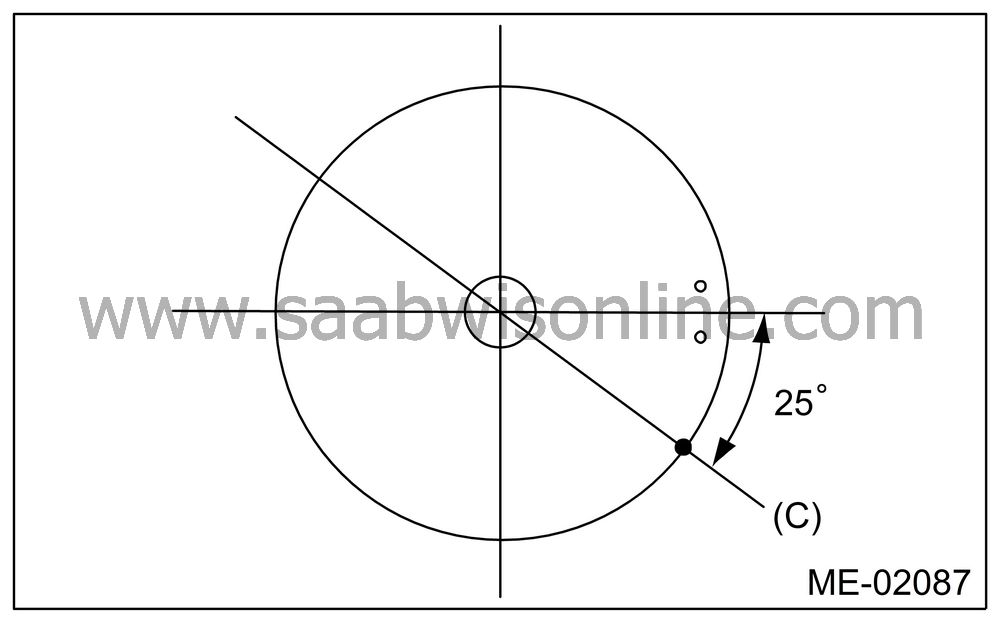

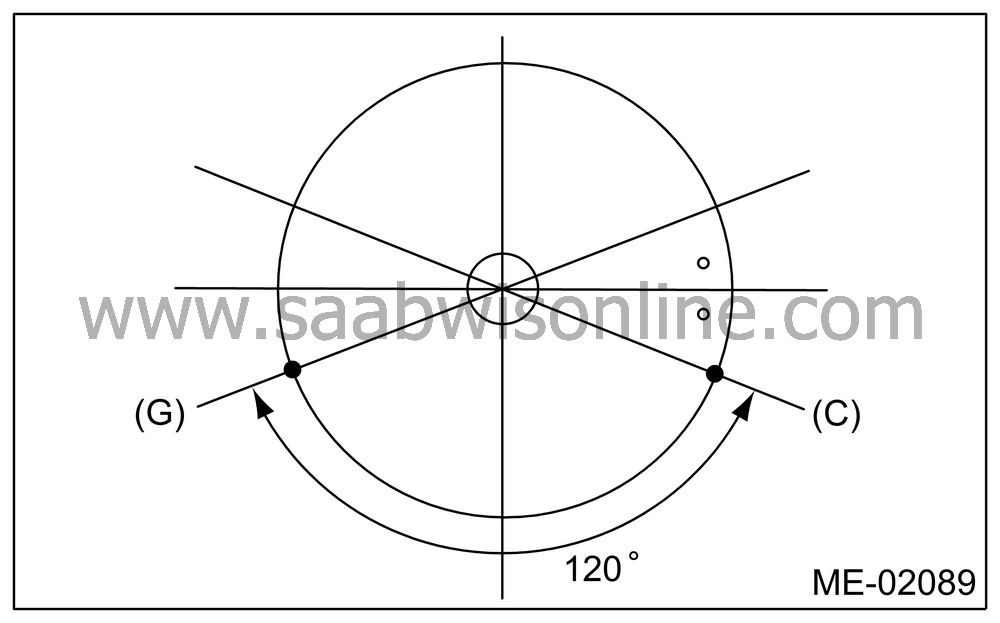

Position the upper rail gap at (C) in the figure.

Align the upper rail spin stopper (E) to the side hole (D) on the piston.

Position the expander gap at 180° on the reverse side of (C) that shown (F) in the figure.

Position the lower rail gap at 120° on counterclockwise of (C) that shown (G) in the figure.

| Important | ||

| • |

Ensure ring gaps do not face

the same direction.

|

|

| • |

Ensure ring gaps are not within the piston skirt area.

|

|

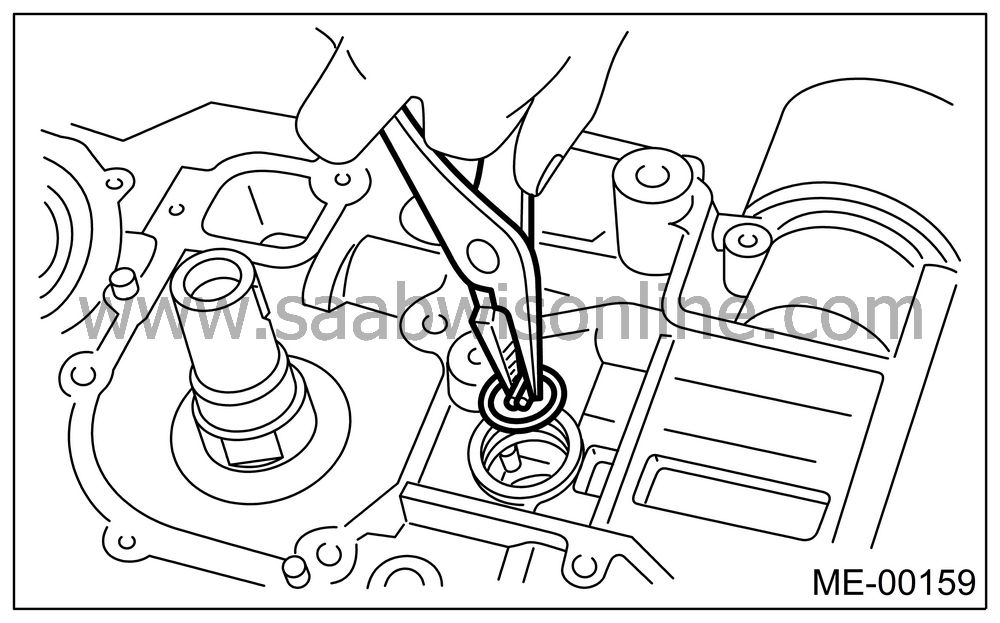

Install the snap ring.

Install snap rings in the piston holes located opposite to the service holes in cylinder block, when positioning all pistons in the corresponding cylinders.

| Note | ||

|

Use new snap rings. |

|

(A)

|

Front side

|

| Important | ||

|

Piston front mark faces towards the front of engine. |

|

(A)

|

Front mark

|

|

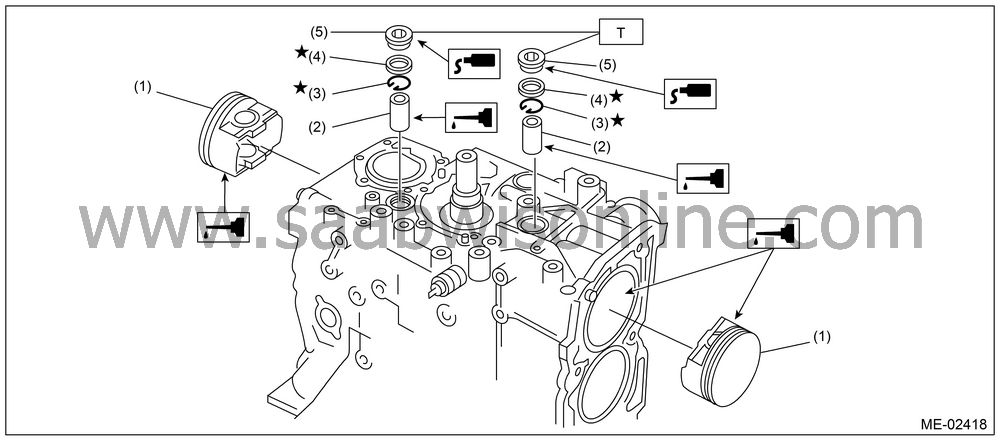

(1)

|

Piston

|

(4)

|

Gasket

|

Tightening torque: Nm (kgf-m, ft-lb)

|

|

|

(2)

|

Piston

pin

|

(5)

|

Service

hole plug

|

T:

|

70 (7.1, 50.6)

|

|

(3)

|

Snap ring

|

||||

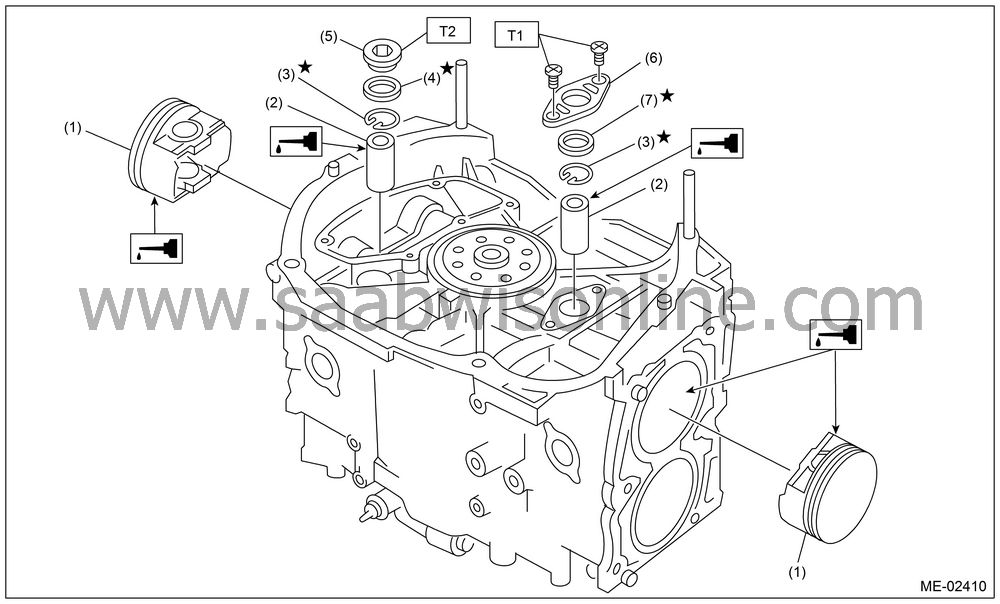

Install the piston.

Place the cylinder block to face the #1 and #2 cylinder side upward.

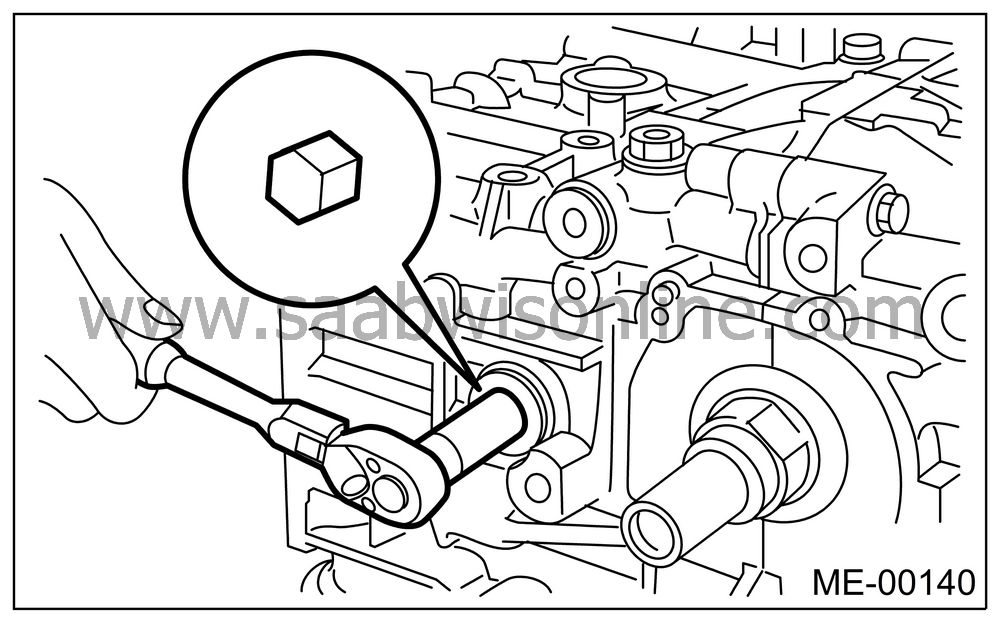

Using ST1, turn the crankshaft so that #1 and #2 connecting rods are set at bottom dead center.

ST1 32005170 CRANKSHAFT SOCKET

Apply a coat of engine oil to the pistons and cylinders and insert pistons in their cylinders using ST2.ST2 32005114 PISTON GUIDE

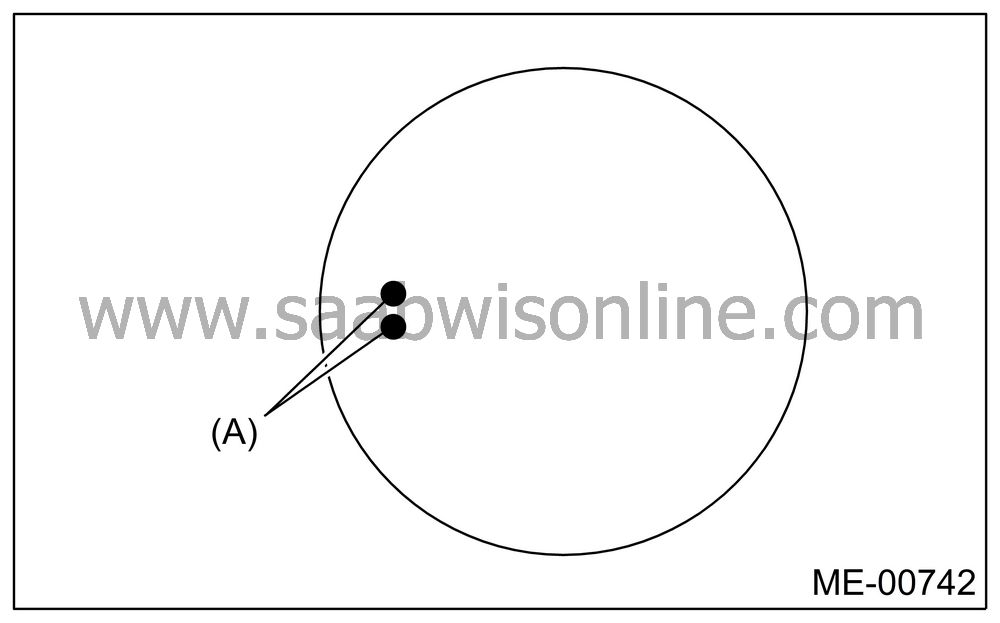

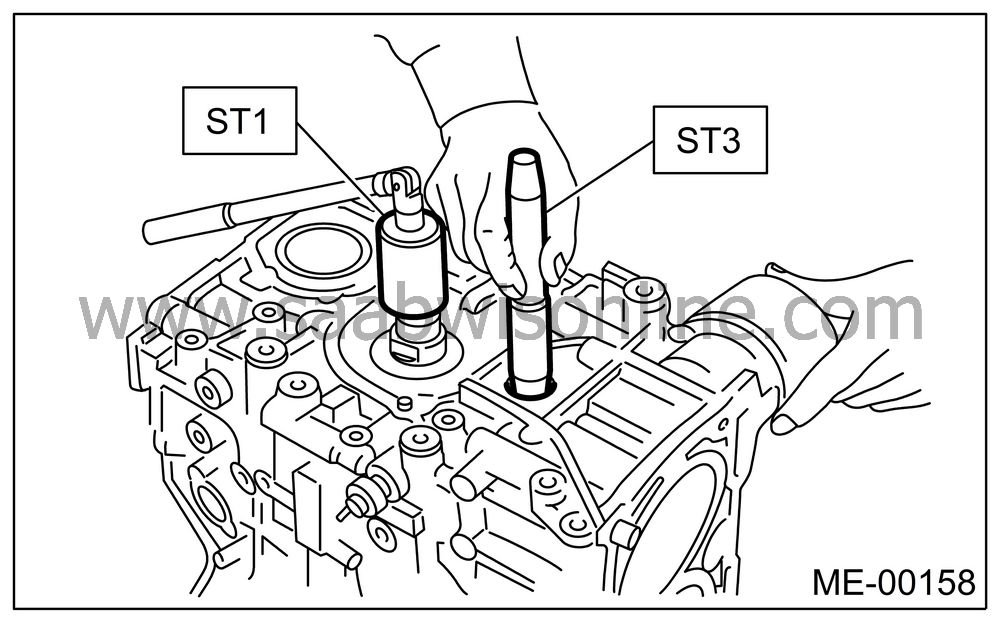

Install the piston pin.

Apply a coat of engine oil to ST3.

Insert ST3 into the service hole to align piston pin hole with connecting rod small end.

ST3 32005121 PISTON PIN GUIDE

Apply a coat of engine oil to piston pin, and insert the piston pin into piston and connecting rod through service hole.

Install the snap ring.

| Note | ||

|

Use new snap rings. |

Apply liquid gasket around the service hole plug.

Liquid gasket:

THREE BOND 1215 (Part No. 32005013) or equivalent

Install the service hole plug and gasket.

| Note | ||

|

Use a new gasket. |

|

(1)

|

Piston

|

(5)

|

Service

hole plug

|

Tightening torque: Nm (kgf-m, ft-lb)

|

|

|

(2)

|

Piston

pin

|

(6)

|

Service

hole cover

|

T1:

|

6.4 (0.65, 4.7)

|

|

(3)

|

Snap ring

|

(7)

|

O-ring

|

T2:

|

70 (7.1, 50.6)

|

|

(4)

|

Gasket

|

||||

Place the cylinder block to face the #3 and #4 cylinder side upward. Following the same procedures as used for #1 and #2 cylinders, install the pistons and piston pins.

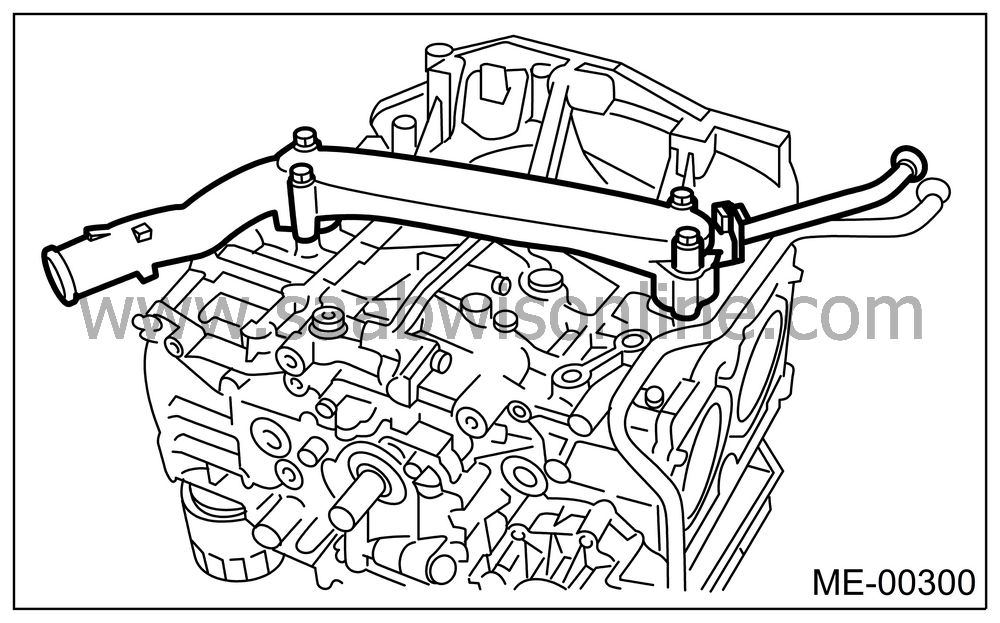

Install the water pipe.

Install the baffle plate.

Tightening torque:

6.4 Nm (0.65 kgf-m, 4.7 ft-lb)

Install the oil strainer and O-ring.

Tightening torque:

10 Nm (1.0 kgf-m, 7.2 ft-lb)

Install the oil strainer stay.

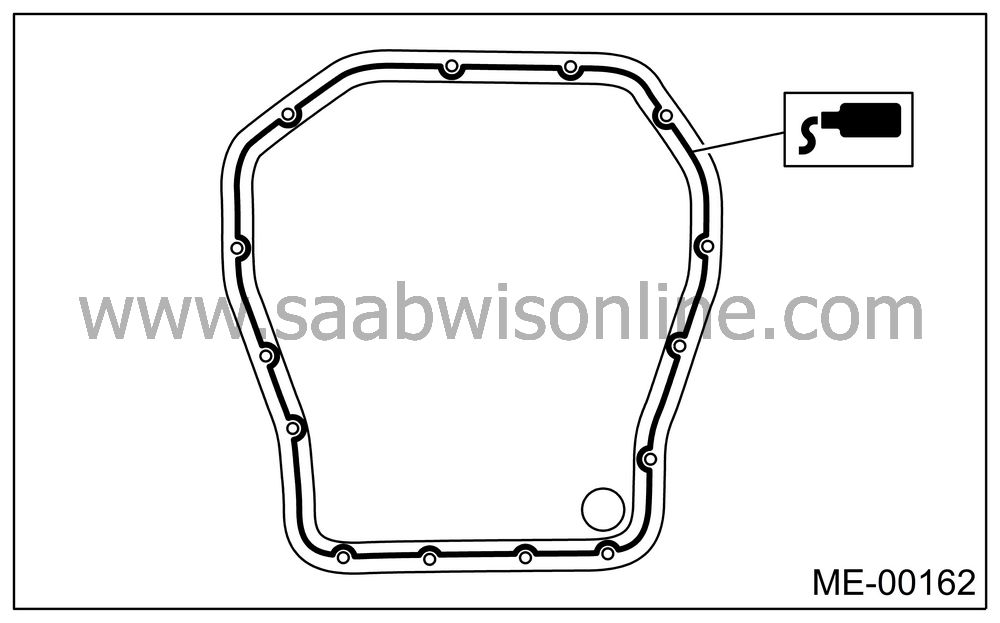

Apply liquid gasket to mating surfaces and install the oil pan.

Liquid gasket:

THREE BOND 1207C (Part No. 32005015) or equivalent

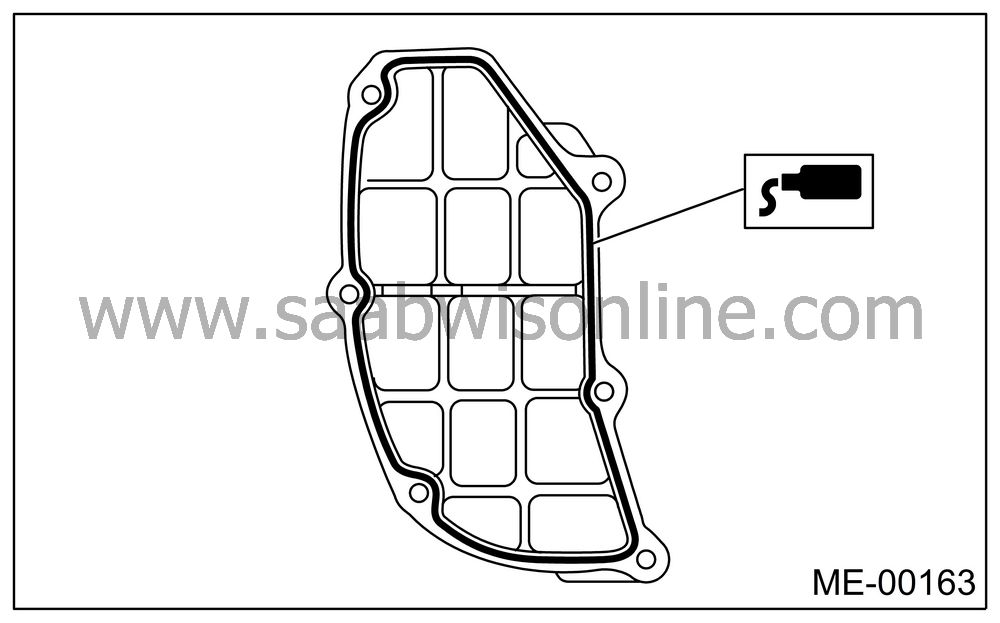

Apply liquid gasket to mating surfaces and install the oil separator cover.

Liquid gasket:

THREE BOND 1207C (Part No. 32005015) or equivalent

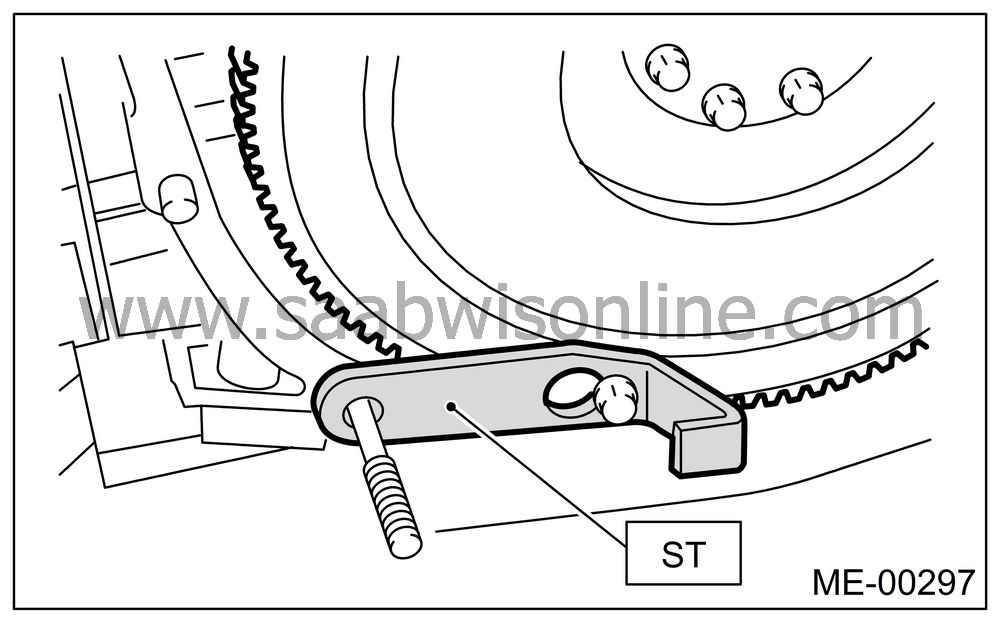

Install the flywheel. (MT model)

To lock the crankshaft, use the ST.

ST 32005107 CRANKSHAFT STOPPER

Tightening torque:72 Nm (7.3 kgf-m, 52.8 ft-lb)

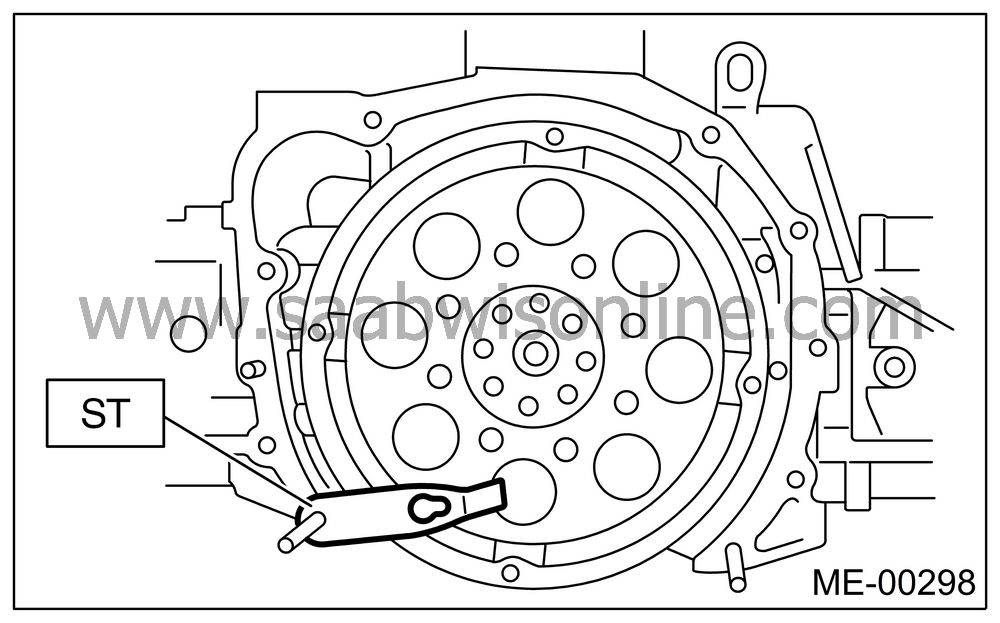

Install the drive plate.

To lock the crankshaft, use the ST.

ST 32005107 CRANKSHAFT STOPPER

Tightening torque:72 Nm (7.3 kgf-m, 52.8 ft-lb)

Install the housing cover.

Installation of oil pump:

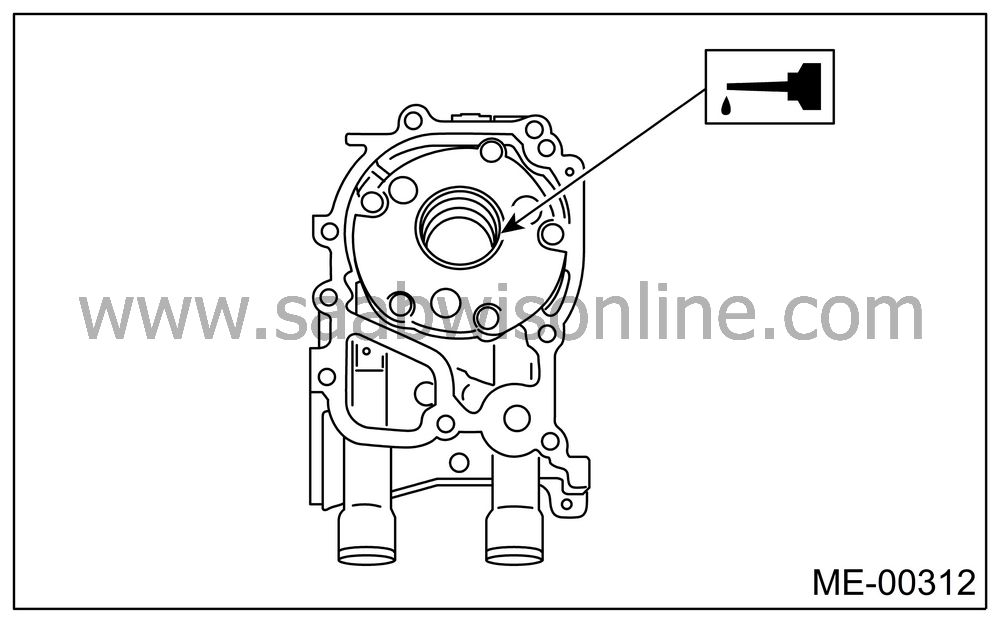

Discard the front oil seal after removal. Replace with a new one using ST.

ST 32005135 OIL SEAL INSTALLER

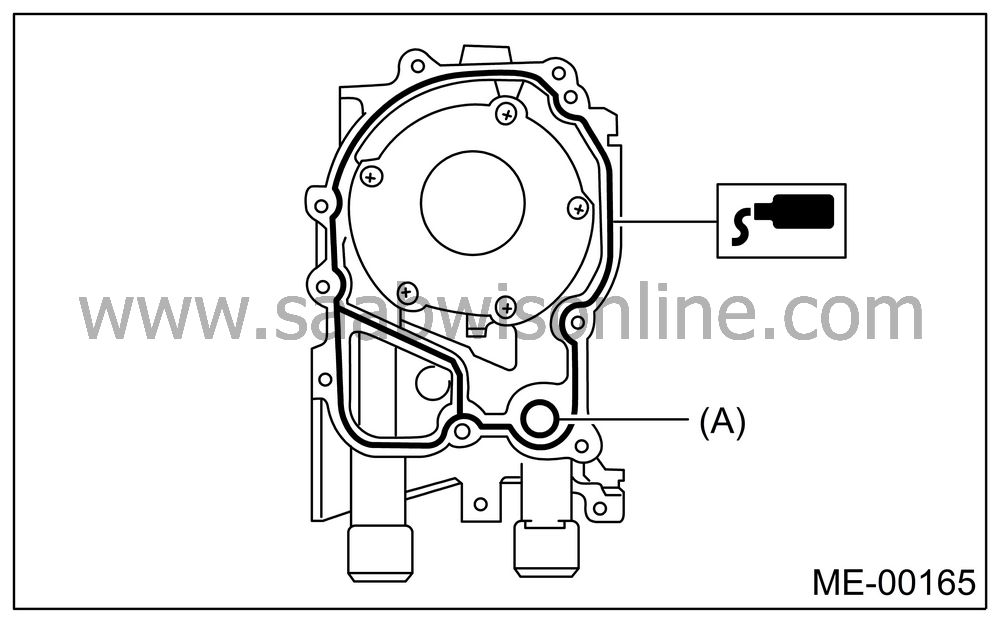

Apply liquid gasket to the matching surface of oil pump.

Liquid gasket:

THREE BOND 1215 (Part No. 32005013) or equivalent

|

(A)

|

O-ring

|

Apply a coat of engine oil to the inside of oil seal.

Install the oil pump on cylinder block. Be careful not to damage the oil seal during installation.

Tightening torque:

6.4 Nm (0.65 kgf-m, 4.7 ft-lb)

| Important | ||

| • |

Do not forget to install the

O-ring and seal when installing the oil pump.

|

|

| • |

Align the flat surface of oil pump’s inner

rotor with crankshaft before installation.

|

|

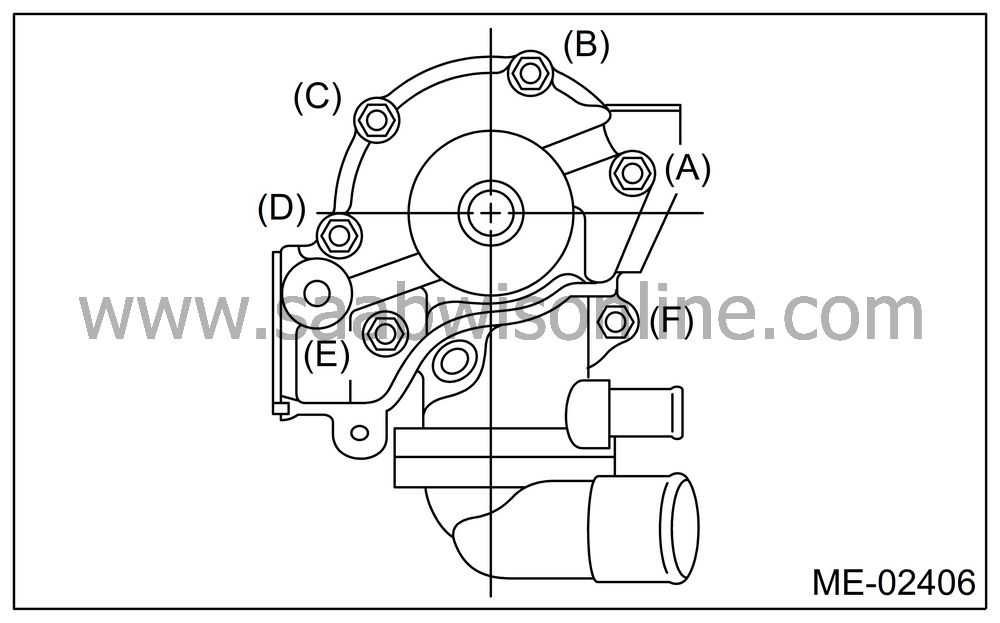

Install the water pump and gasket.

Tightening torque:

First: 12 Nm (1.2 kgf-m, 8.7 ft-lb)

Second: 14 Nm (1.4 kgf-m, 10.2 ft-lb)

| Important | ||

| • |

Be sure to use a new gasket.

|

|

| • |

When installing the water pump, tighten bolts in two

stages in alphabetical sequence as shown in the figure.

|

|

Install the water by-pass pipe for heater.

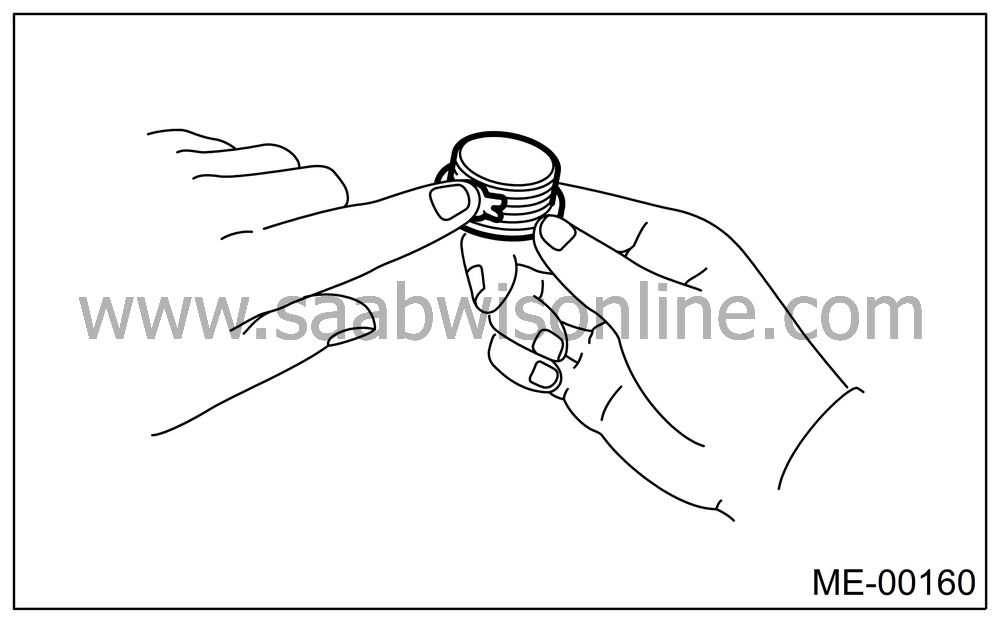

Install the oil filter using ST.

ST 32005021 OIL FILTER WRENCH (Outer diameter: 68 mm (2.68 in))

Install the oil filter by turning it by hand, being careful not to damage the seal rubber.Tighten the oil filter 68 mm (2.68 in) in diameter by approx. 1 rotation more after the seal rubber of oil filter comes in contact with cylinder block or oil cooler.

| Important | ||

|

Do not tighten excessively, or oil may leak. |

||

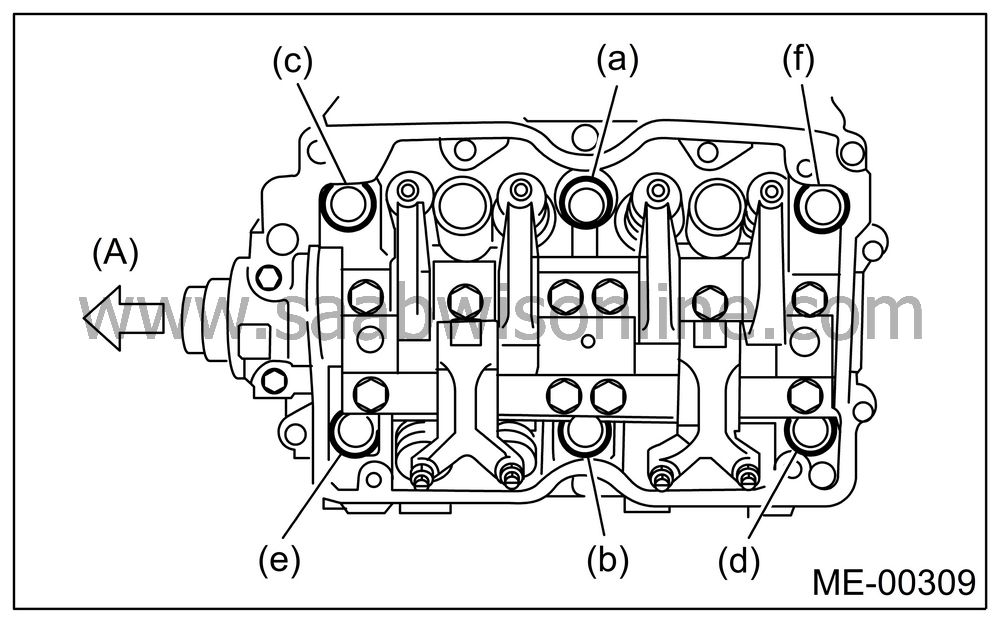

Tighten the cylinder head bolts.

Apply a coat of engine oil to washers and bolt threads.

Tighten all bolts to 29 Nm (3.0 kgf-m, 22 ft-lb) in alphabetical sequence. Then tighten all bolts to 69 Nm (7.0 kgf-m, 51 ft-lb) in alphabetical sequence.

Back off all bolts by 180° first; and back them off again by 180°.

Tighten the bolts (a) and (b) to 34 Nm (3.5 kgf-m, 25 ft-lb).

Tighten the bolts (c), (d), (e) and (f) to 15 Nm (1.5 kgf-m, 11 ft-lb).

Tighten all bolts by 80° — 90° in alphabetical sequence.

| Important | ||

|

Do not tighten the bolts more than 90°. |

||

Further tighten all bolts by 80° — 90° in alphabetical sequence.

| Important | ||

|

Ensure the total “re-tightening angle” of the step (6) and (7) does not exceed 180°. |

||

|

(A)

|

Front side

|

Install the oil level gauge guide and tighten the bolt (left side only).

Install the rocker cover and rocker cover gasket.

| Note | ||

|

Use new rocker cover gasket. |

Install the crank sprocket.

Install the cam sprocket.

Install the timing belt.

Install the timing belt cover.

Install the crank pulley.

Install the generator and A/C compressor brackets on cylinder head.

Install the V-belts.

Install the intake manifold.