INSTALLATION

| INSTALLATION |

| AUTOMATIC BELT TENSION ADJUSTER ASSEMBLY AND BELT IDLER |

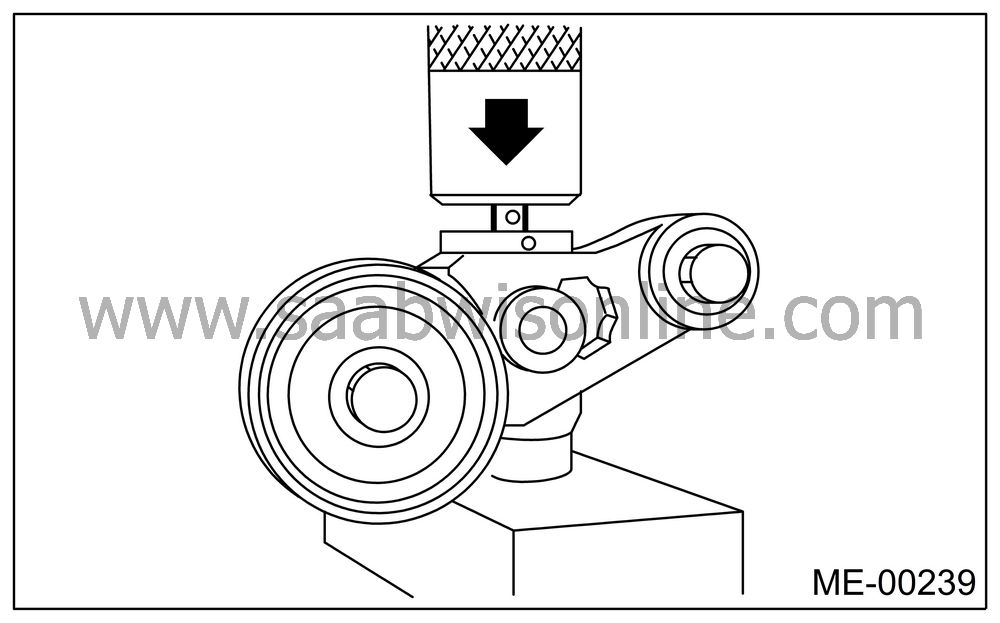

Preparation for installation of automatic belt tension adjuster assembly.

| Important | ||

| • |

Always use a vertical type pressing

tool to move the adjuster rod down.

|

|

| • |

Do not use a lateral type vise.

|

|

| • |

Push the adjuster rod vertically.

|

|

| • |

Press-in the push adjuster rod gradually taking more

than three minutes.

|

|

| • |

Do not allow press pressure to exceed 9,807 N (1,000

kgf, 2,205 lb).

|

|

| • |

Press the adjuster rod as far as the end surface of

the cylinder. Do not press the adjuster rod into cylinder. Doing

so may damage the cylinder.

|

|

| • |

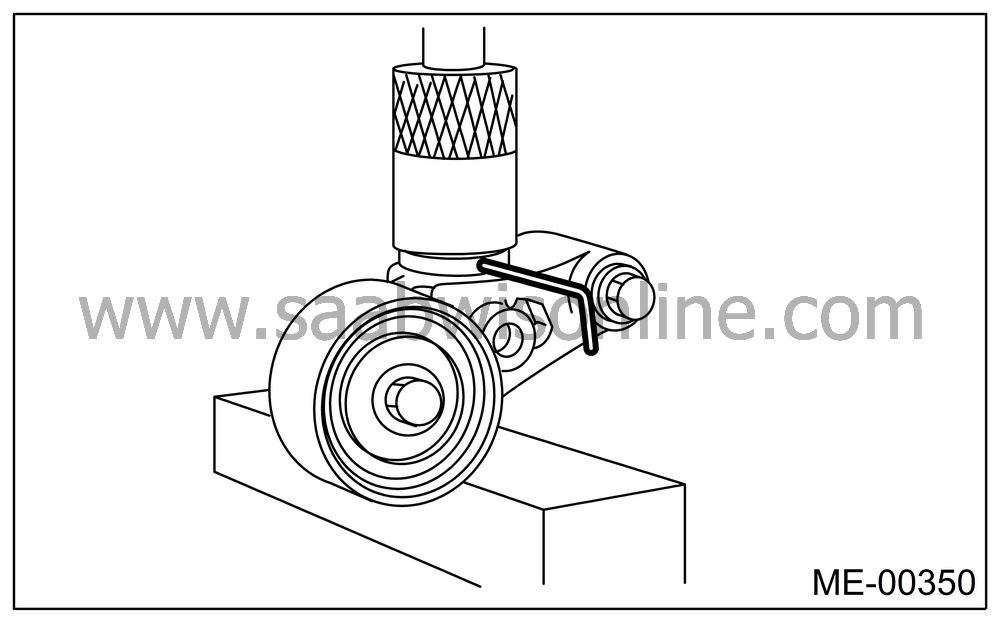

Do not release the press pressure until stopper pin

is completely inserted.

|

|

Attach the automatic belt tension adjuster assembly to the vertical pressing tool.

Slowly move the adjuster rod down with a pressure of 294 N (30 kgf, 66 lb) until the adjuster rod is aligned with the stopper pin hole in the cylinder.

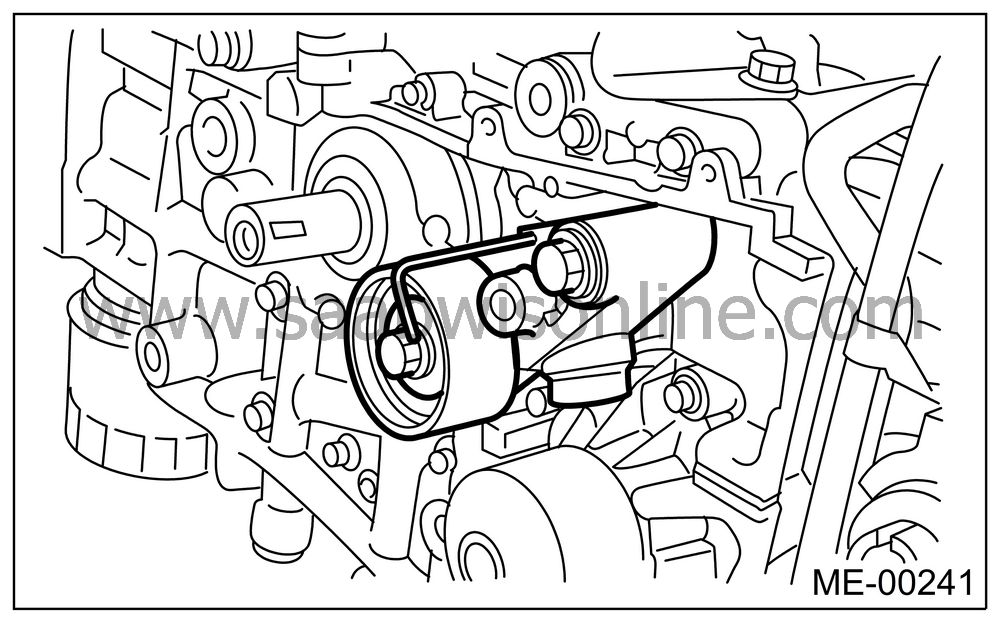

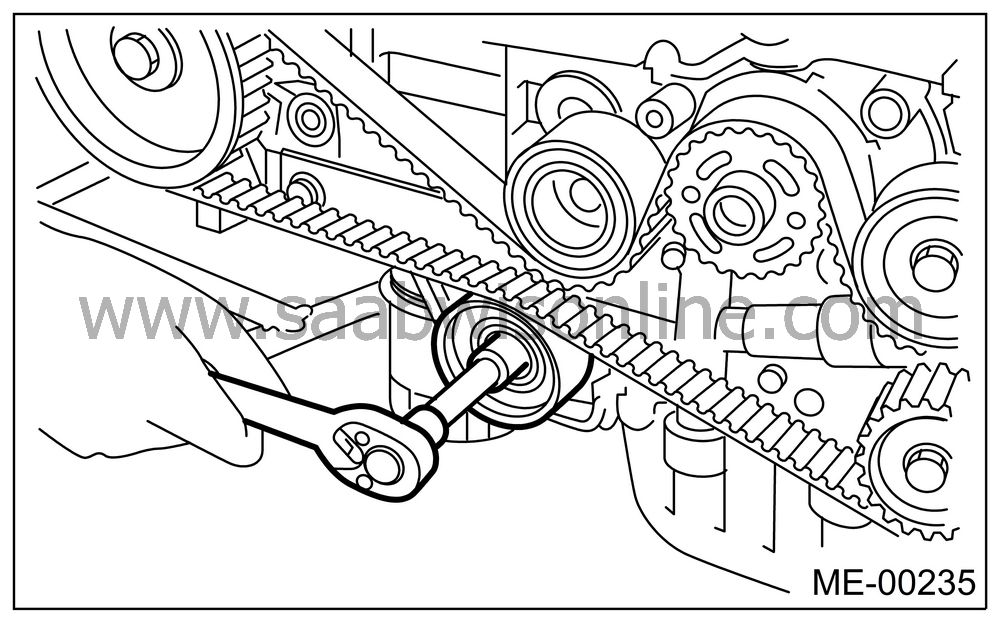

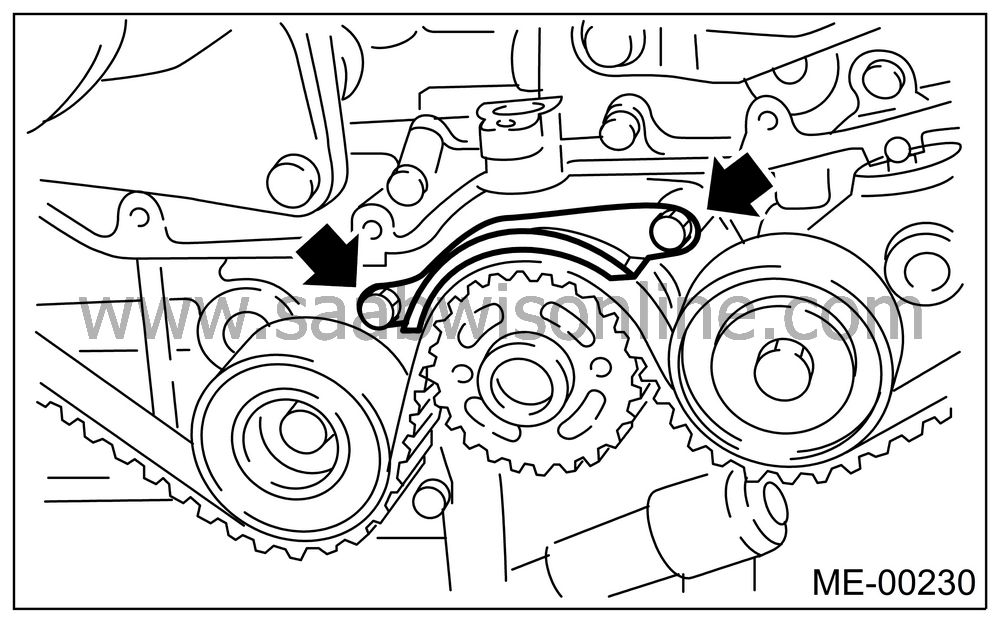

Install the automatic belt tension adjuster assembly.

Tightening torque:

39 Nm (4.0 kgf-m, 28.9 ft-lb)

Install the belt idler (No. 1).

Tightening torque:

39 Nm (4.0 kgf-m, 28.9 ft-lb)

| TIMING BELT |

Prepare for installation of automatic belt tension adjuster assembly.

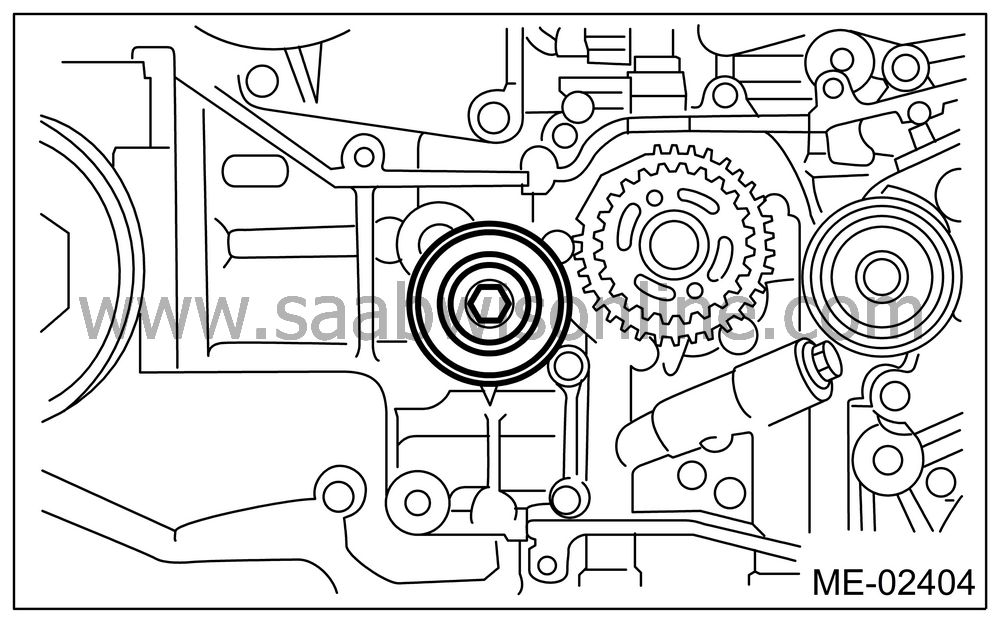

Installation of timing belt:

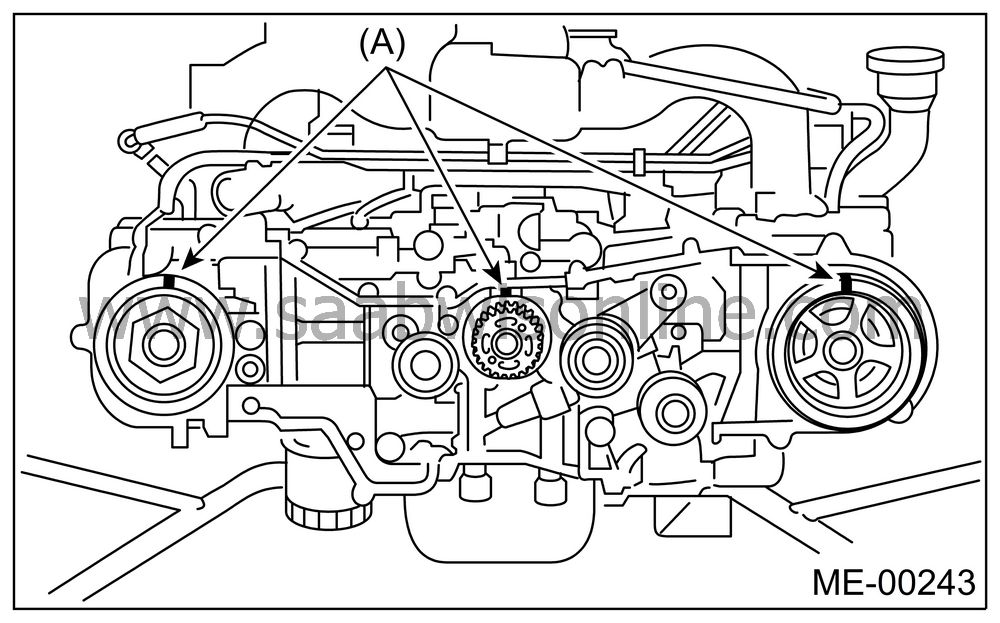

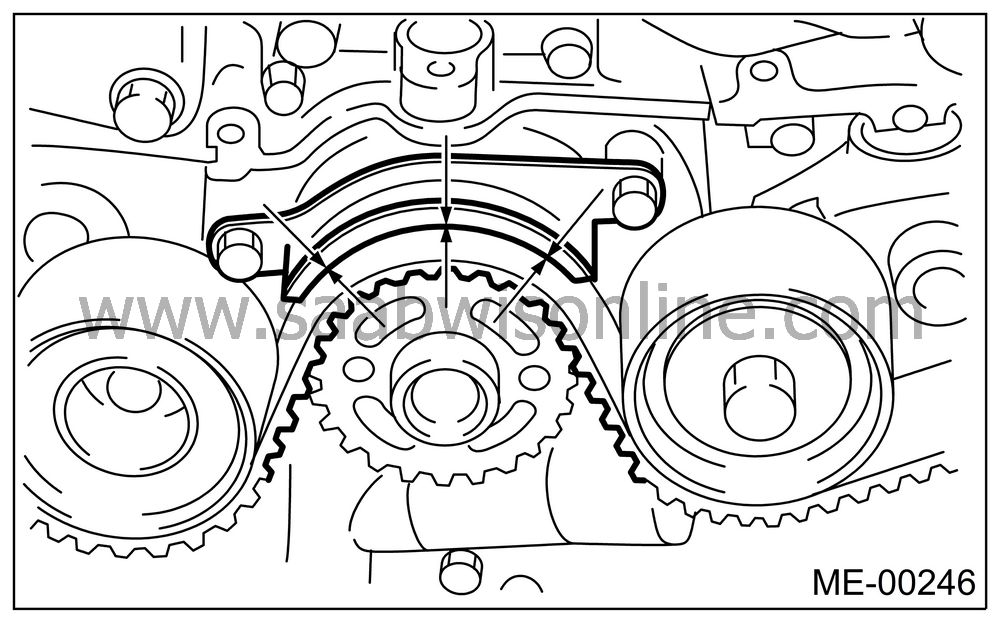

Turn the cam sprocket No. 2 using ST1, and turn the cam sprocket No. 1 using ST2 so that their alignment marks (A) come to top positions.

ST1 32005019 CAM SPROCKET WRENCH

ST2 32005125 CAM SPROCKET WRENCH

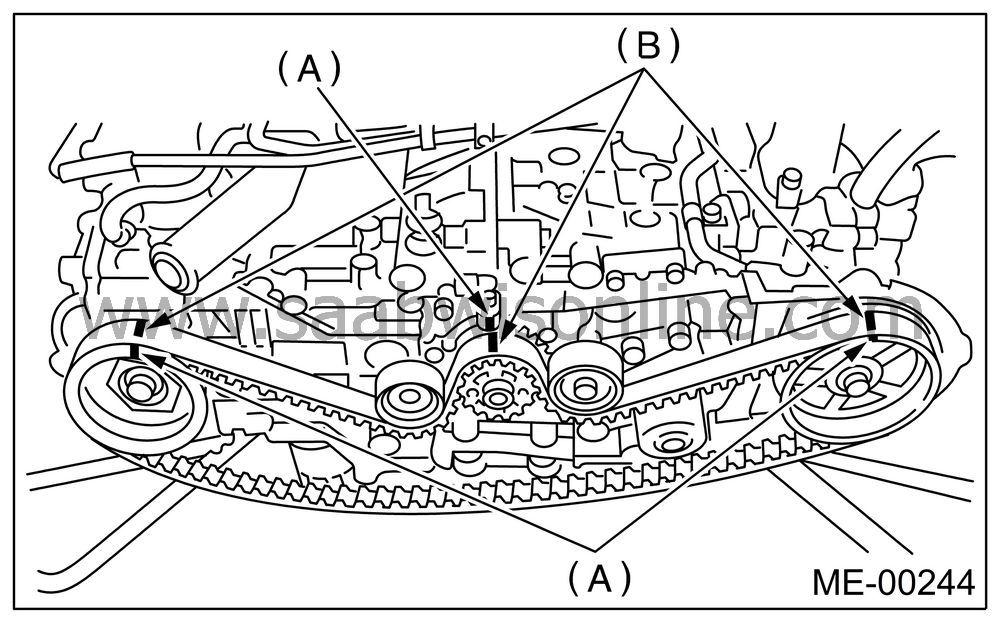

While aligning the alignment mark (B) on timing belt with the mark (A) on sprockets, position the timing belt properly.

Install the belt idler No. 2.

Tightening torque:

39 Nm (4.0 kgf-m, 28.9 ft-lb)

Install the belt idler (No. 2).

Tightening torque:

39 Nm (4.0 kgf-m, 28.9 ft-lb)

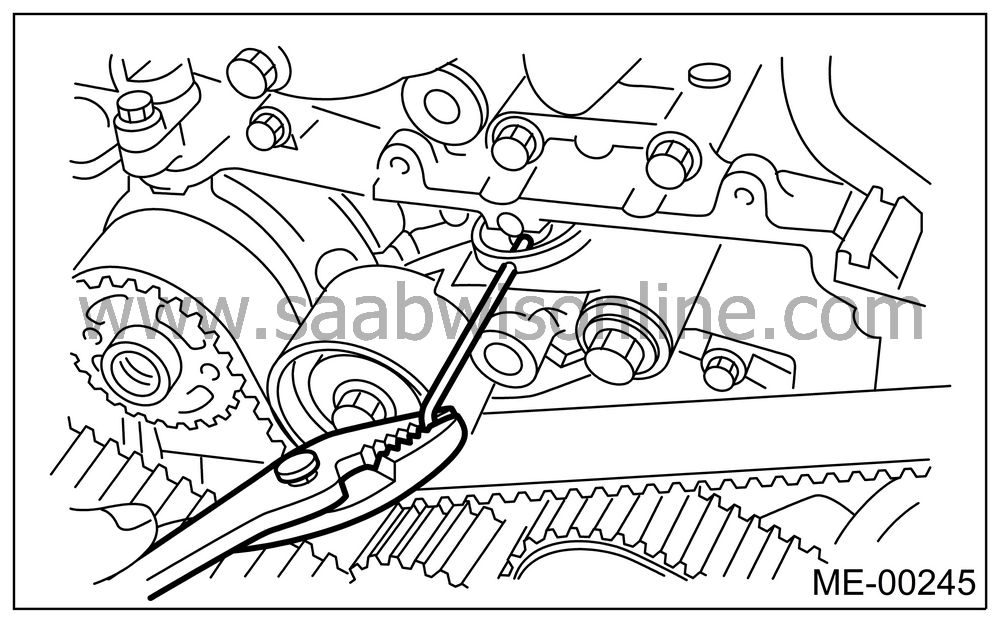

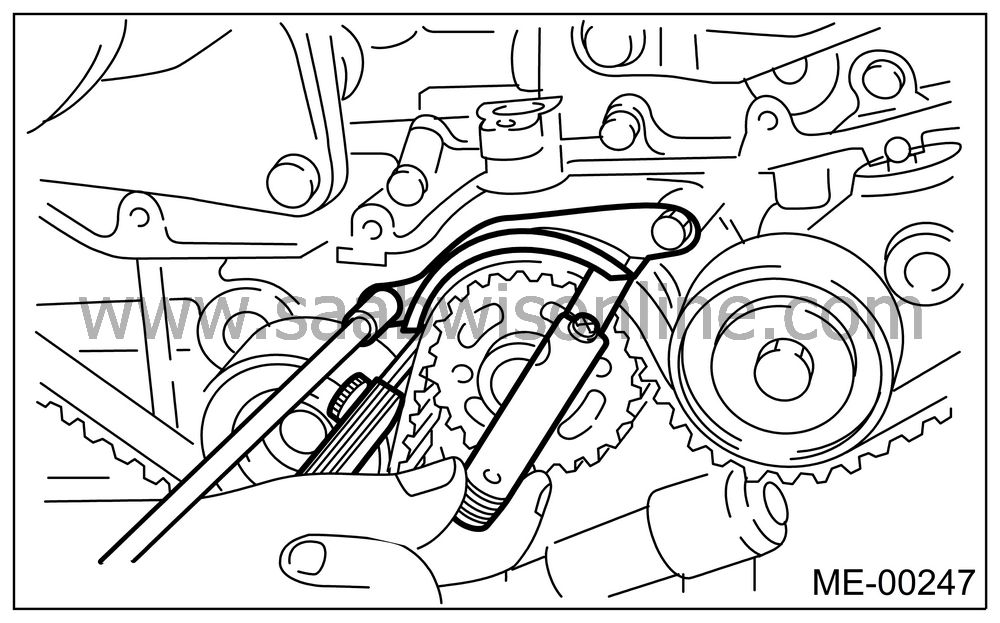

After ensuring the marks on timing belt and cam sprockets are aligned, remove the stopper pin from belt tension adjuster.

Install the timing belt guide. (MT model)

Temporarily tighten the timing belt guide mounting bolts.

Check and adjust the clearance between timing belt and timing belt guide by using thickness gauge.

Clearance:

1.0±0.5 mm (0.039±0.020 in)

Tighten the timing belt guide mounting bolts.

Tightening torque:

10 Nm (1.0 kgf-m, 7.2 ft-lb)

Install the timing belt cover.

Install the crank pulley.

Install the V-belts.