PROCEDURE

| PROCEDURE |

| Important | ||

| • |

The FMVSS No. 116, fresh DOT3 or

DOT4 brake fluid must be used.

|

|

| • |

Cover the bleeder with waste cloth when loosening it

to prevent brake fluid from being splashed over surrounding parts.

|

|

| • |

Do not allow brake fluid to come in contact with vehicle

body; wash away with water and wipe off completely if spilled.

|

|

| • |

Avoid mixing different brands of brake fluid to prevent

degrading the quality of the fluid.

|

|

| • |

Be careful not to allow dirt or dust to get into the

reservoir tank.

|

|

| MASTER CYLINDER |

| Note | ||

| • |

If the master cylinder is disassembled or reservoir

tank is empty, bleed the master cylinder.

|

|

| • |

During the bleeding operation, keep the brake reservoir

tank filled with brake fluid to eliminate entry of air.

|

|

| • |

The brake pedal operating must be very slow.

|

|

| • |

For convenience and safety, two people should do the

work.

|

|

Loosen the wheel nuts, jack-up the vehicle, support it with rigid racks, and remove the wheel.

Disconnect the brake line at primary and secondary sides.

Put a plastic bag cover on master cylinder.

Carefully depress and hold the brake pedal.

Repeat step 4) and 5) until the brake fluid is completely bled from outlet plug.

Remove the plastic bag.

Install the brake pipes to master cylinder.

Tightening torque:

15 Nm (1.5 kgf-m, 10.8 ft-lb)

Bleed air from the brake line.

| BRAKE LINE |

| Note | ||

| • |

During the bleeding operation, keep the brake reservoir

tank filled with brake fluid to eliminate entry of air.

|

|

| • |

The brake pedal operating must be very slow.

|

|

| • |

For convenience and safety, two people should do the

work.

|

|

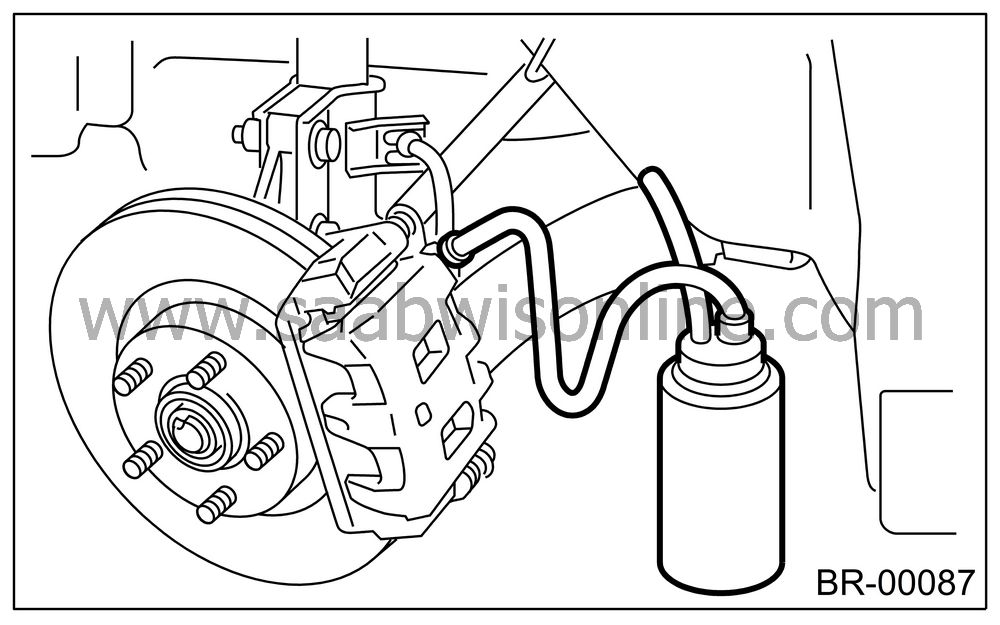

Make sure that there is no leak from the joints and connections of brake system.

Fit one end of vinyl tube into the air bleeder and put the other end into a brake fluid container.

| Important | ||

|

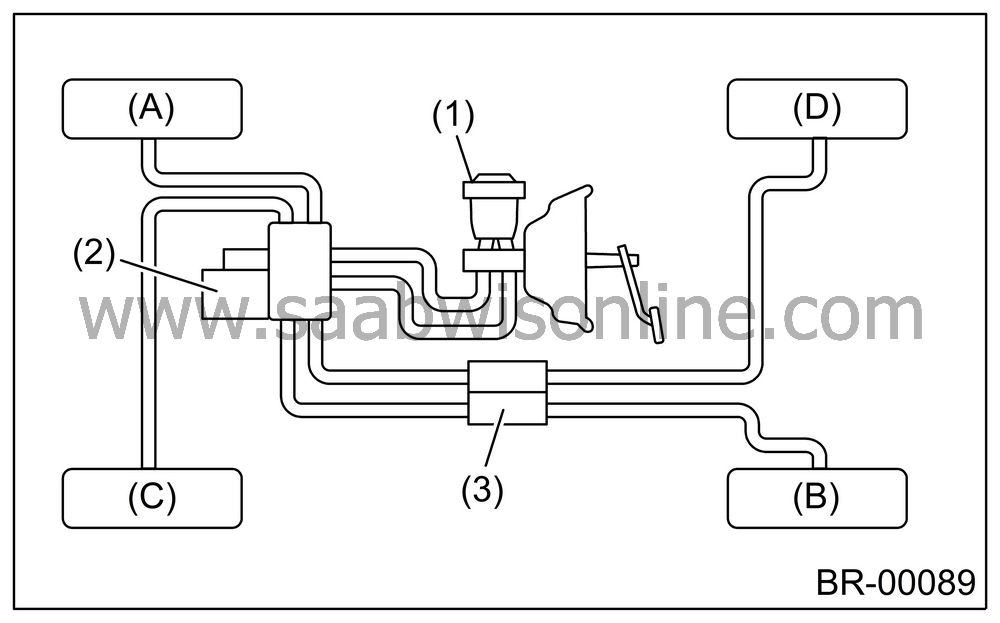

Brake fluid replacement sequence; (A) Front right → (B) Rear left → (C) Front left → (D) Rear right |

|

(1)

|

Master

cylinder

|

|

(2)

|

Hydraulic

unit

|

|

(3)

|

Proportioning

valve

|

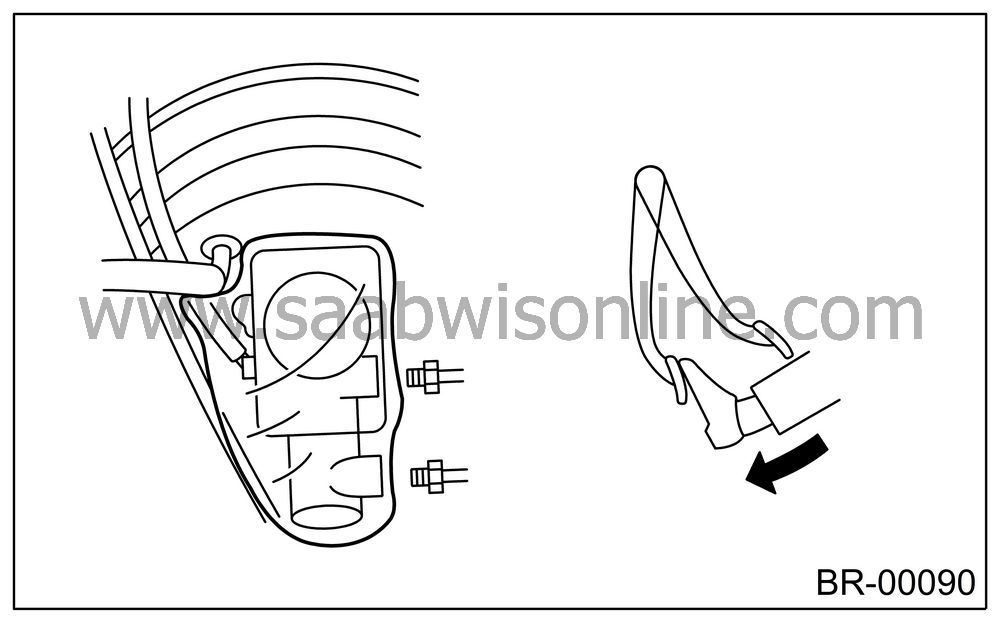

Slowly depress the brake pedal and keep it depressed. Then, open the air bleeder to discharge air together with the fluid.

Release the air bleeder for 1 to 2 seconds.

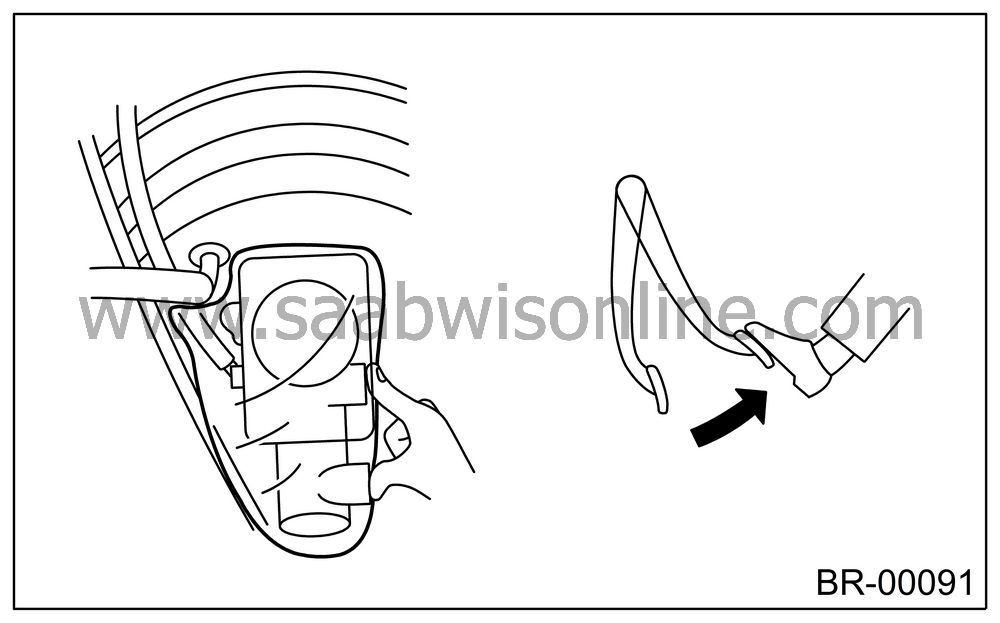

Next, with the bleeder closed, slowly release the brake pedal.

Repeat these steps until there are no more air bubbles in the vinyl tube.

Allow 3 to 4 seconds between two brake pedal operations.

| Important | ||

|

Cover the bleeder with waste cloth, when loosening it, to prevent brake fluid from being splashed over surrounding parts. |

||

| Note | ||

|

The brake pedal operating must be very slow. |

Tighten the air bleeder securely when no air bubbles are visible.

Air bleeder tightening torque:

8 Nm (0.8 kgf-m, 5.8 ft-lb)

Perform these steps for the brakes connecting to secondary chamber of master cylinder, first, and then for the ones connecting to primary chamber. With all procedures completed, fully depress the brake pedal and keep it in that position for approx. 20 seconds to make sure that there is no leak evident in the entire system.

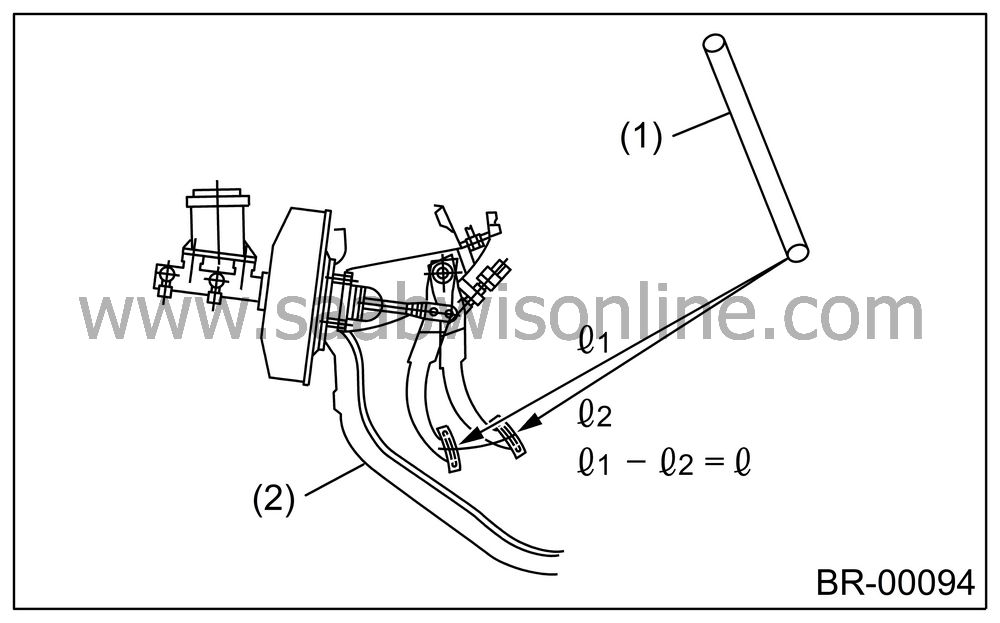

Check the pedal stroke.

While the engine is idling, depress the brake pedal with a 490 N (50 kgf, 110 lb) load and measure the distance between brake pedal and steering wheel. With the brake pedal released, measure the distance between pedal and steering wheel again. The difference between the two measurements must not be more than specified.

|

(1)

|

Steering

wheel

|

|

(2)

|

Toe board

|

Specified pedal stroke

Saab 9-2X 2.0T Aero AT model

105 mm (4.13 in)Except Saab 9-2X 2.0T Aero AT model

90 mm (3.54 in)When depressing brake pedal with a 490 N (50 kgf, 110 lbf) load.

If the distance is more than the specifications, there is a possibility that air is in the brake line. Bleed the brake line until pedal stroke meets the specification.

Operate the hydraulic control unit in the sequence control mode.

Recheck the pedal stroke.

If the distance is more than specifications, there is a possibility air is in the inside of hydraulic unit. Repeat above steps 2) to 9) above until pedal stroke meets the specification.

Add brake fluid to the required level (MAX. level) of reservoir tank.

As a final step, test run the vehicle at low speed and apply brakes relatively hard 2 to 3 times to ensure that brakes provide normal braking action on all four wheels without dragging and uneven braking.