Checking for lateral runout and variation in thickness, front wheels

|

|

Checking for lateral runout and variation in thickness, front wheels

|

|

1.

|

Raise the car and remove the front wheels.

|

|

2.

|

Start checking on one side. Press in the brake piston, using a pair of slip-joint pliers.

|

|

3.

|

Remove

the brake caliper completely without disconnecting the brake line and suspend the caliper using a cable tie.

|

|

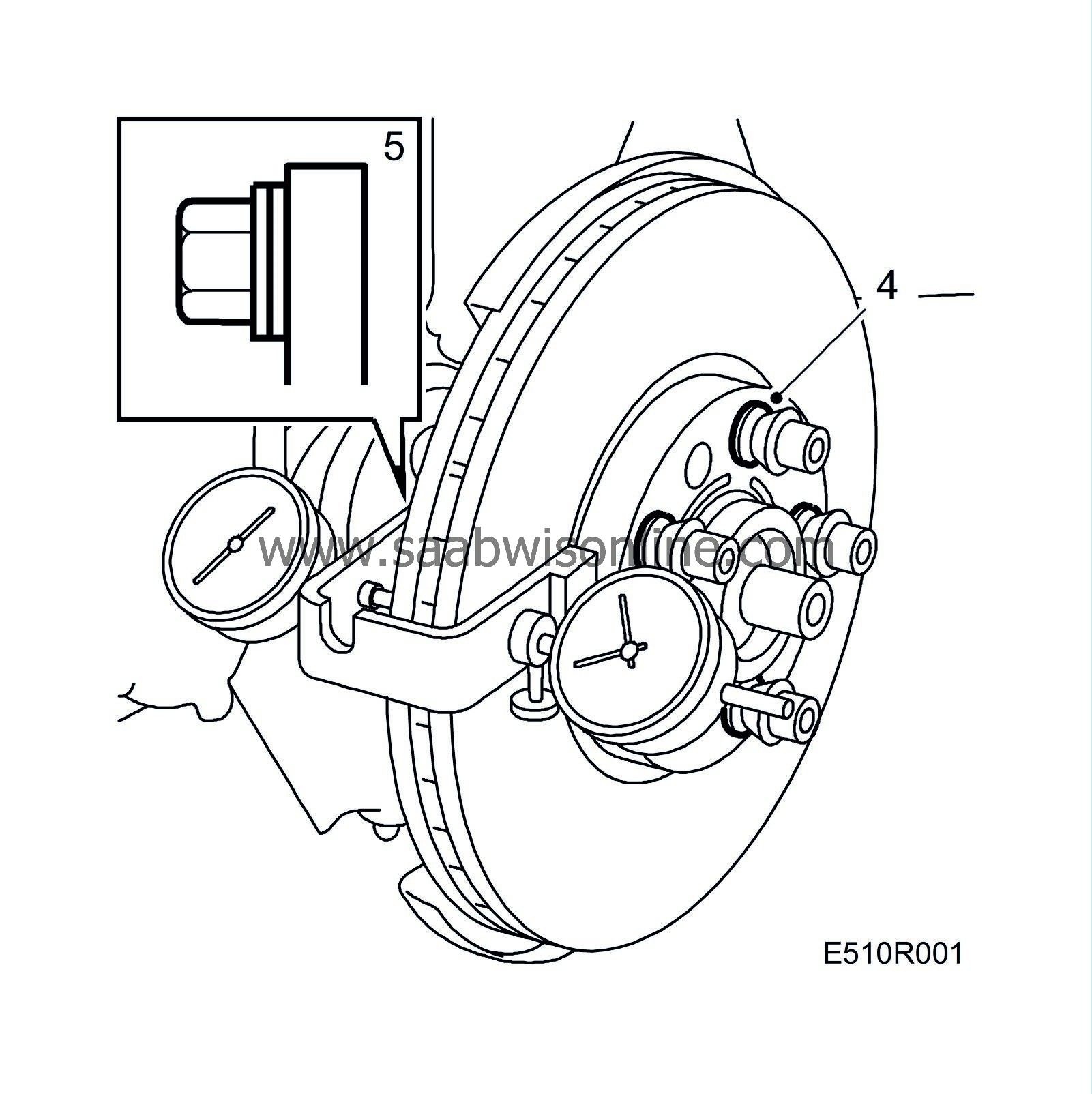

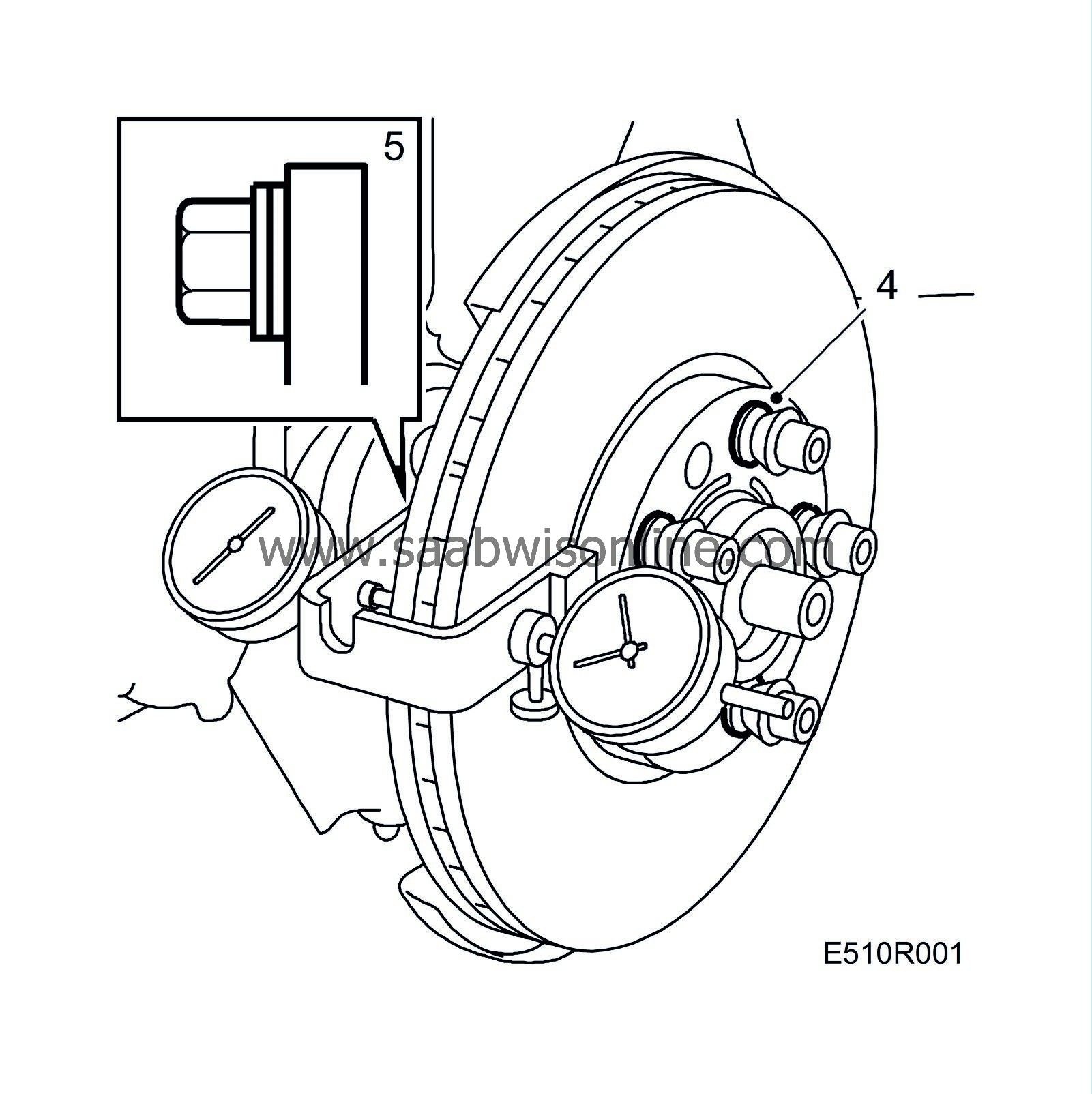

4.

|

Fit the five wheel bolts with one washer, part no. 80 73 124, on each.

|

|

5.

|

Mount the brake disc measuring tool on the lower retaining lug for the brake caliper, fitting washers in between so that the mounting screws do not reach the brake disc. Fit a

dial gauge, 78 40 622

on each side.

|

|

6.

|

Rotate the brake disc while observing the outboard dial gauge. Zero both gauges when the negative reading obtained on the outboard one is at maximum.

|

|

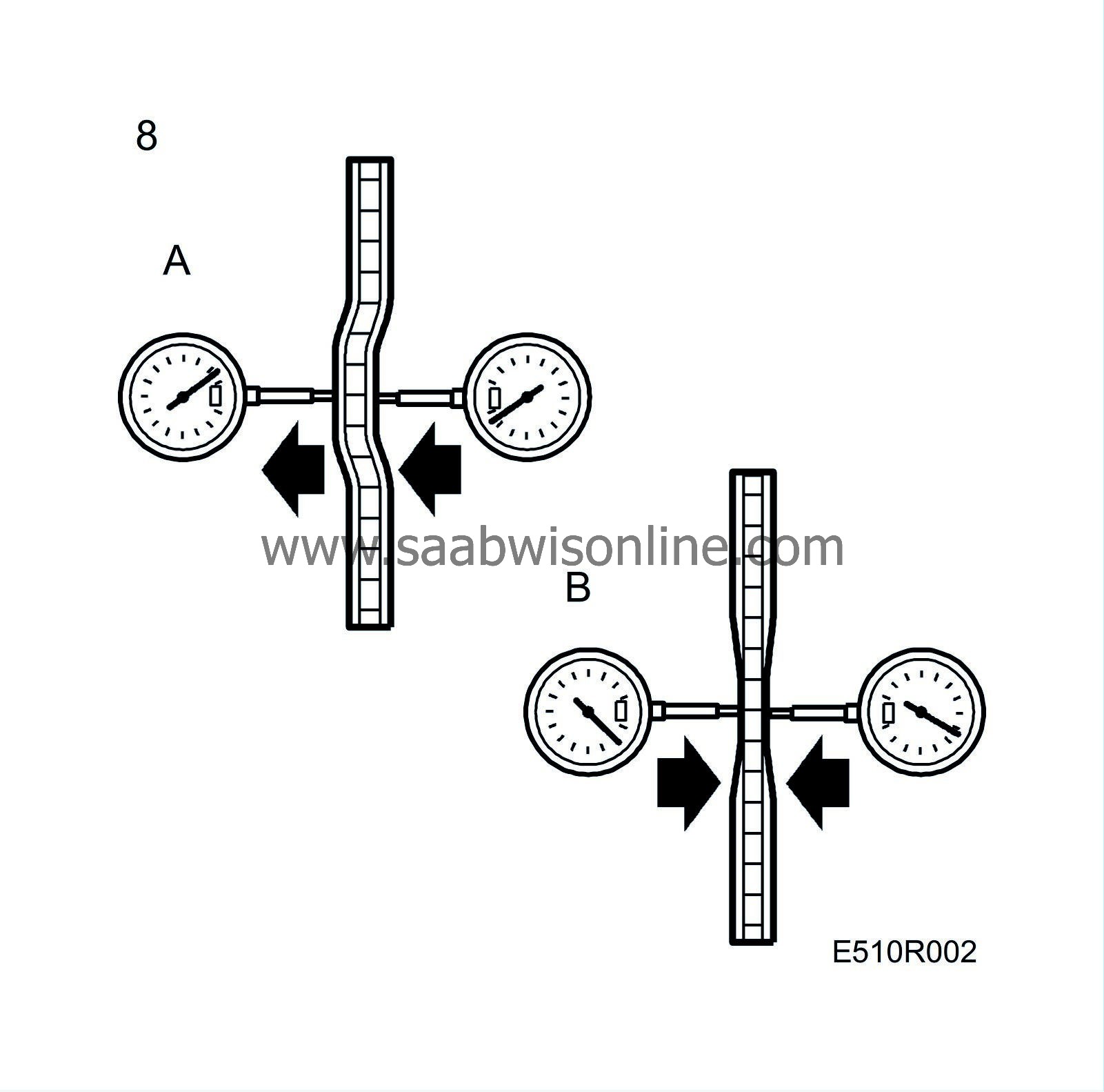

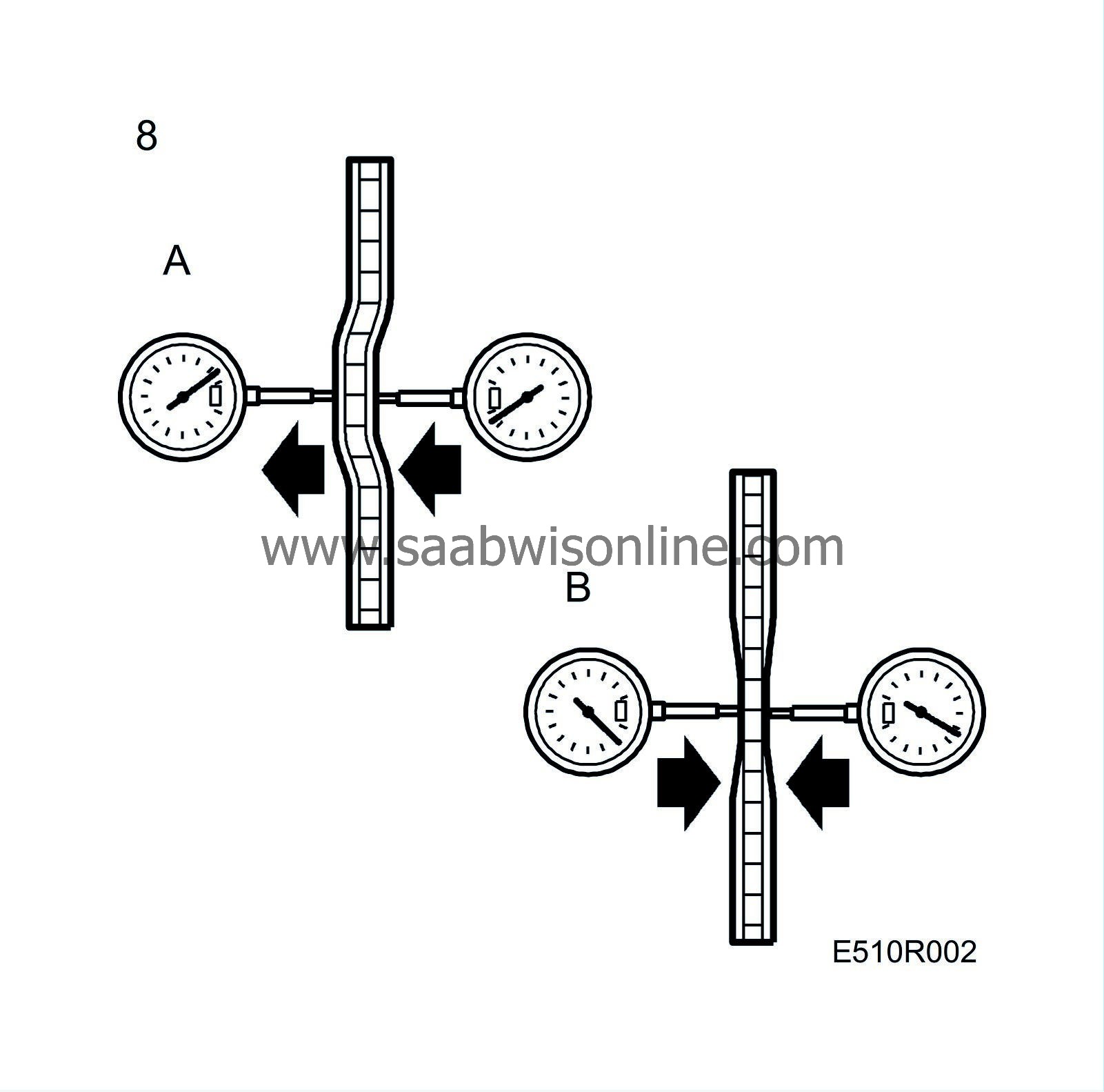

8.

|

Rotate the disc and read the gauges. Note the runout (A) and variation in thickness (B).

|

|

9.

|

Remove the dial gauges, brake disc measuring tool and wheel studs with washers.

|

|

11.

|

Fit

the brake caliper, apply Loctite 242 to the stud threads and tighten the studs, using a torque wrench.

Tightening torque 117 Nm (81 lbf ft)

|

|

12.

|

Fit the wheels, see

Wheels

.

Tightening torque 110 Nm (81 lbf ft).

|

Important

|

|

The wheel must hang freely when the wheel bolts are being tightened.

|

|

|

|

|

13.

|

Repeat this method of measurement on the other front wheel.

|

|

14.

|

When the measurements have been completed, lower the car and depress the brake pedal to press out the brake pads.

|