Valve Clearance Adjustment (LLU/A16LET)

|

|

Valve Clearance Adjustment (LLU/A16LET)

|

Special Tools

For equivalent regional tools, refer to

Special Tools

.

|

1.

|

|

Note

|

|

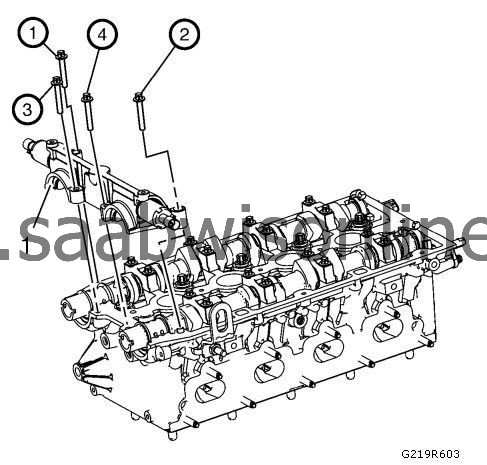

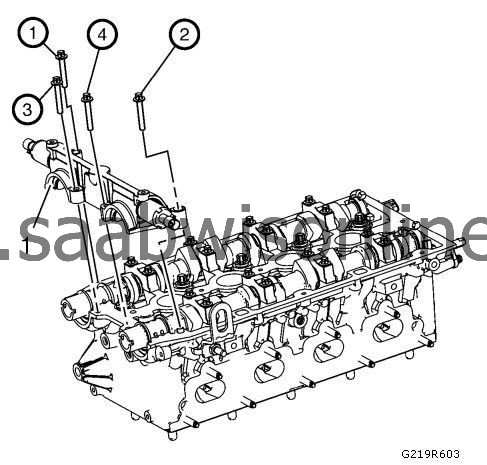

Counterhold at hexagon of camshaft.

|

Inspect the 2 valve lash, intake valve cylinder 1.

|

|

|

1.1.

|

Turn the intake camshaft in the direction of engine rotation by the camshaft hexagon until the cams of cylinder 1 are in the test position.

|

|

|

1.2.

|

Insert the

EN-6361

gauge , inspect the valve lash.

|

|

|

1.3.

|

Write down the result.

|

|

2.

|

Inspect the 2 valve lash, intake valve cylinder 3.

|

|

|

2.1.

|

Turn the intake camshaft in the direction of engine rotation by the camshaft hexagon until the cams of cylinder 3 are in the test position.

|

|

|

2.2.

|

Insert the

EN-6361

gauge , inspect the valve lash.

|

|

|

2.3.

|

Write down the result.

|

|

3.

|

Inspect the 2 valve lash, intake valve cylinder 4.

|

|

|

3.1.

|

Turn the intake camshaft in the direction of engine rotation by the camshaft hexagon until the cams of cylinder 4 are in the test position.

|

|

|

3.2.

|

Insert the

EN-6361

gauge , inspect the valve lash.

|

|

|

3.3.

|

Write down the result.

|

|

4.

|

Inspect the 2 valve lash, intake valve cylinder 2.

|

|

|

4.1.

|

Turn the intake camshaft in the direction of engine rotation by the camshaft hexagon until the cams of cylinder 2 are in the test position.

|

|

|

4.2.

|

Insert the

EN-6361

gauge , inspect the valve lash.

|

|

|

4.3.

|

Write down the result.

|

|

5.

|

When replacing the exhaust camshaft, inspect the valve lash of the exhaust valves.

|

|

6.

|

Inspect the 2 valve lash, exhaust valve cylinder 4.

|

|

|

6.1.

|

Turn the exhaust camshaft in the direction of engine rotation by the camshaft hexagon until the cams of cylinder 4 are in the test position.

|

|

|

6.2.

|

Insert the

EN-6361

gauge , inspect the valve lash.

|

|

|

6.3.

|

Write down the result.

|

|

7.

|

Inspect the 2 valve lash, exhaust valve cylinder 2.

|

|

|

7.1.

|

Turn the exhaust camshaft in the direction of engine rotation by the camshaft hexagon until the cams of cylinder 2 are in the test position.

|

|

|

7.2.

|

Insert the

EN-6361

gauge , inspect the valve lash.

|

|

|

7.3.

|

Write down the result.

|

|

8.

|

Inspect the 2 valve lash, exhaust valve cylinder 1.

|

|

|

8.1.

|

Turn the exhaust camshaft in the direction of engine rotation by the camshaft hexagon until the cams of cylinder 1 are in the test position.

|

|

|

8.2.

|

Insert the

EN-6361

gauge , inspect the valve lash.

|

|

|

8.3.

|

Write down the result.

|

|

9.

|

Inspect the 2 valve lash, exhaust valve cylinder 3.

|

|

|

9.1.

|

Turn the exhaust camshaft in the direction of engine rotation by the camshaft hexagon gear until the cams of cylinder 3 are in the test position.

|

|

|

9.2.

|

Insert the

EN-6361

gauge , inspect the valve lash.

|

|

|

9.3.

|

Write down the result.

|

|

10.

|

|

Note

|

|

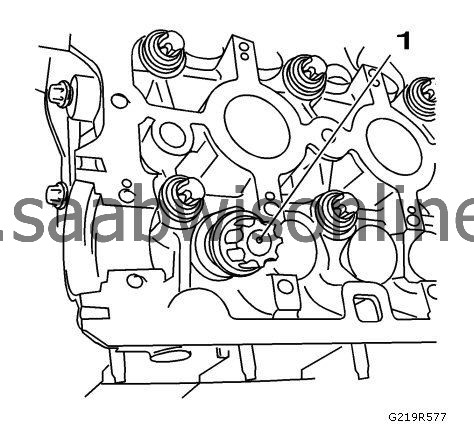

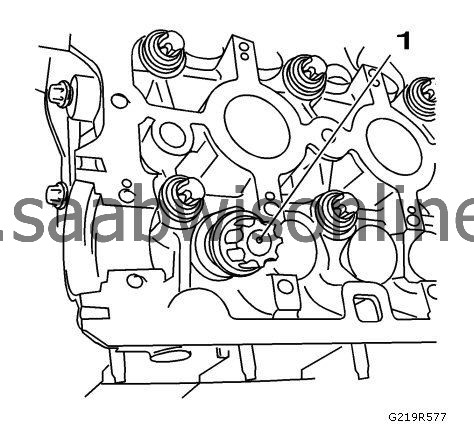

Note the removal sequence 1-4. Mark the exhaust and intake camshaft bearing caps before removal.

|

Remove the 4 camshaft bearing front cap fasteners in sequence from the camshaft bearing front cap (1).

|

|

11.

|

Release the intake bearing support by striking it gently with a plastic hammer.

|

|

12.

|

Remove the camshaft bearing front cap.

|

|

13.

|

Detach the intake camshaft bearing caps 1-4 working from outside to inside in a spiral in steps of 1/2 up to 1 turn.

|

|

14.

|

Remove the intake camshaft bearing cover from the cylinder head.

|

|

15.

|

Remove the intake camshaft.

|

|

16.

|

Detach the exhaust camshaft bearing caps 1-4 working from outside to inside in a spiral in steps of 1/2 up to 1 turn.

|

|

17.

|

Remove the exhaust camshaft bearing cover from the cylinder head.

|

|

18.

|

Remove the exhaust camshaft.

|

|

19.

|

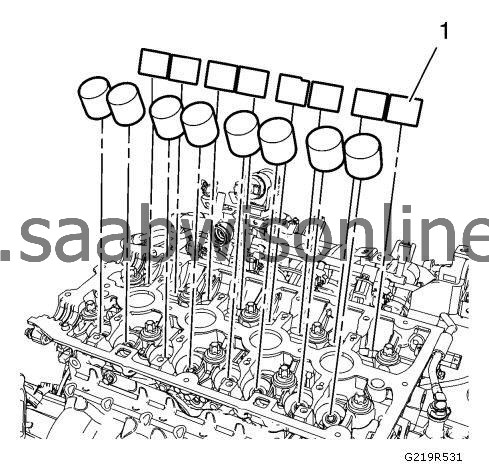

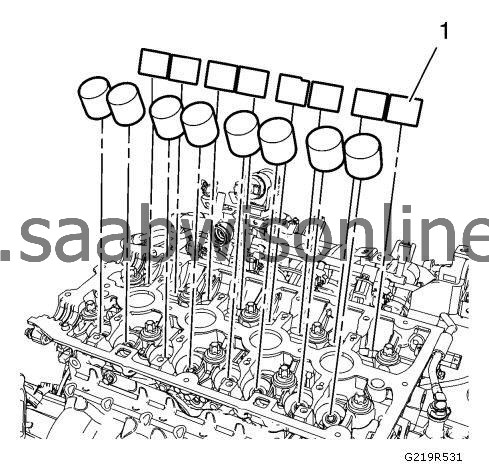

Using the

EN-845

device (1), remove the 16 valve tappets.

|

|

20.

|

Determine valve lifter size.

|

|

|

•

|

Measurement of the cup tappet installed

3.12 mm (0.123 in)

, identification number 12. Measured value between cams and cup tappets

+0.31 mm (0.012 in)

=

3.43 mm (0.135 in)

. Required value, valve lash -

0.25 mm (0.010 in)

.

|

|

|

•

|

|

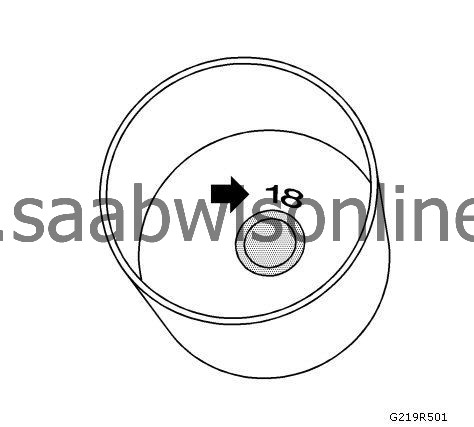

Note

|

|

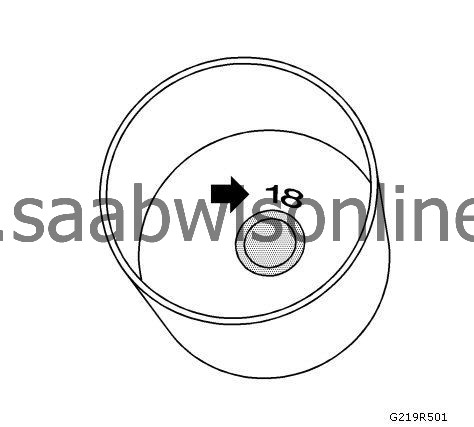

The identification number, arrow, is on the inside of the valve tappet.

|

Measurement of the new cup tappet =

3.18 mm (0.125 in)

, identification number 18. Use a valve tappet with this dimension or one that is nearest to it.

|

|

1.

|

|

Note

|

|

Observe the correct assignment and coat the sliding surfaces with NEW engine oil.

|

Install the 16 valve lifters (1); use the

EN 845

suction device.

|