Valve Stem Oil Seal and Valve Spring Replacement

|

|

Valve Stem Oil Seal and Valve Spring Replacement

|

Special Tools

|

•

|

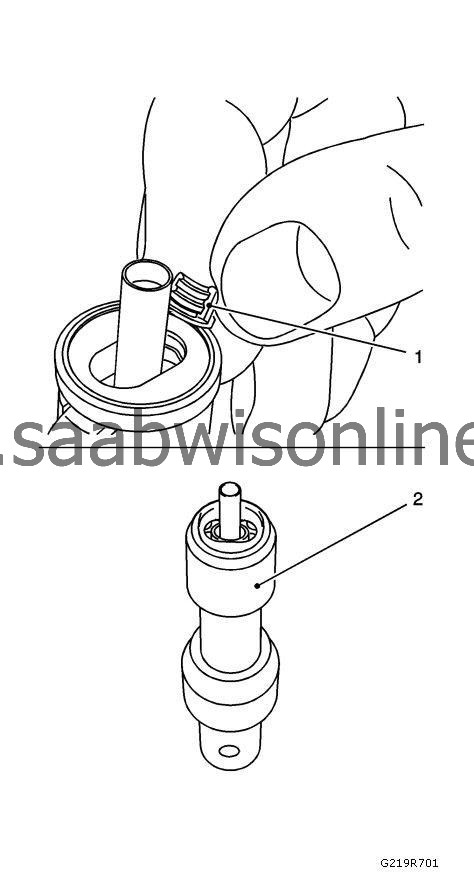

EN-958

Installation Tool

|

|

•

|

EN-6625

Flywheel Holder

|

|

•

|

EN-6086

Basic Kit, Spring and Wedge Replacer

|

|

•

|

EN-889

Automatic Valve Spring Lever

|

For equivalent regional tools, refer to

Special Tools

Special Tools.

|

2.

|

Remove the spark plugs. Refer to

Spark Plug Replacement

.

|

Note

|

|

180 degrees offset to marking ignition TDC cylinder number 1.

|

|

|

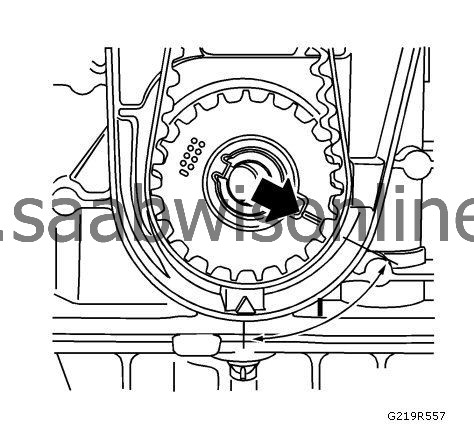

3.

|

Make alignment mark on the toothed belt drive belt.

|

|

4.

|

Turn the crankshaft to ignition TDC marking, cylinder number 1.

|

|

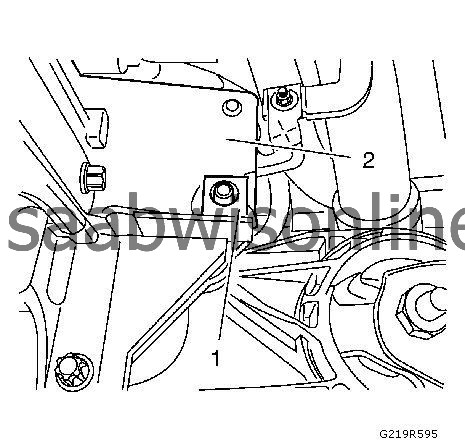

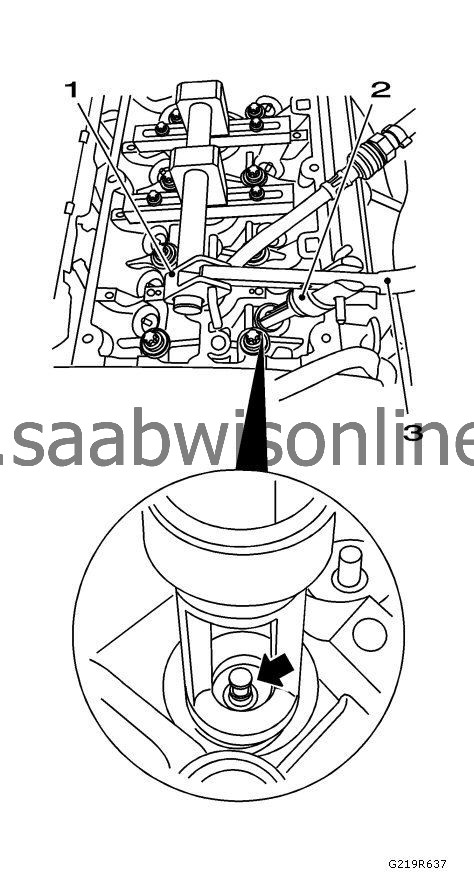

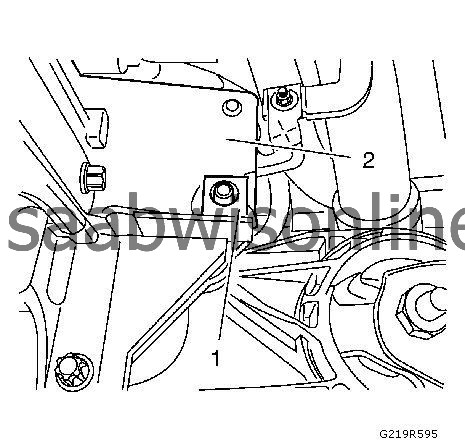

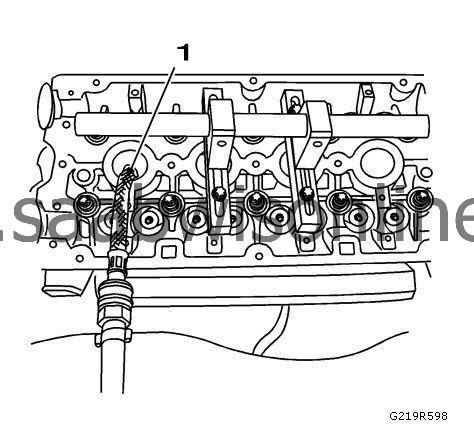

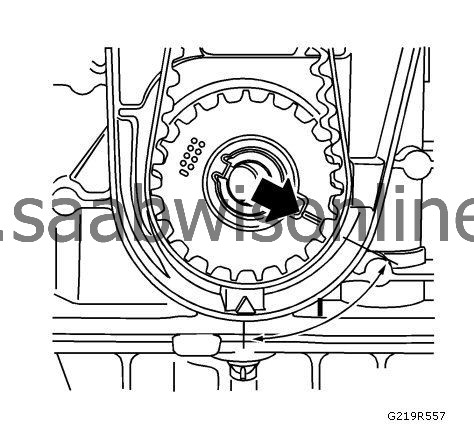

7.

|

Install

EN-6625

flywheel holder (1) to the engine block (2).

|

|

8.

|

Lower the vehicle by its full height.

|

|

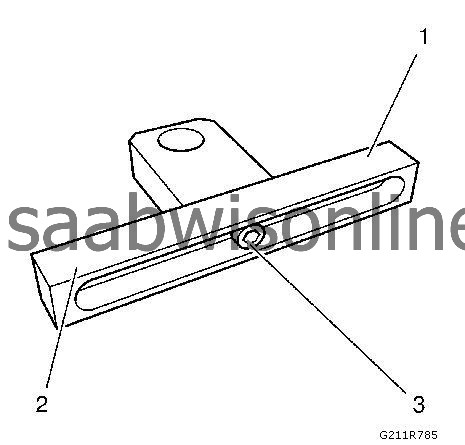

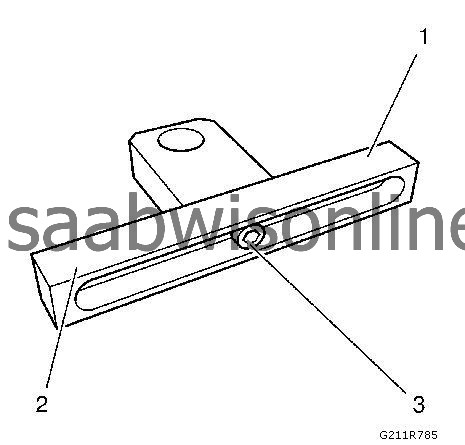

10.

|

Tighten one of the support head (1) in the center of the rail (2) with the fastener (3).

|

|

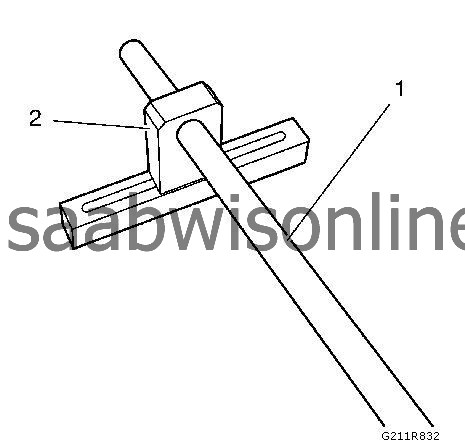

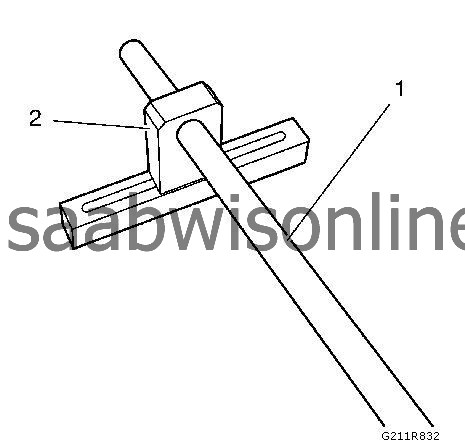

11.

|

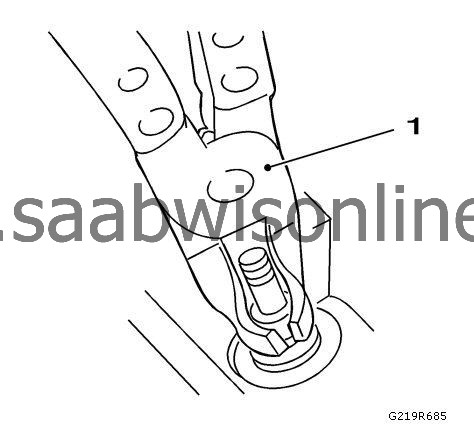

Install the

EN-6086-5

mounting shaft (1) to one of the

EN-6086-6

supports (2).

|

|

12.

|

Install the second support to the mounting shaft.

|

|

13.

|

Install the lever arm bracket to the cylinder head.

|

|

14.

|

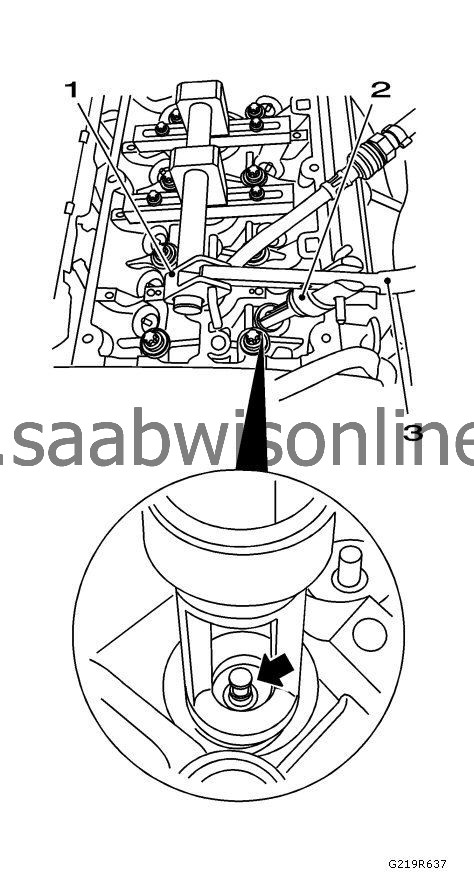

Attach the

EN-6086-15

pneumatic adapter (1).

|

|

|

14.1.

|

Attach the adapter to cylinder number 1.

|

|

|

14.2.

|

Apply compressed air to cylinder number 1.

|

|

15.

|

Attach the

EN-6086-7

lever arm (3).

|

|

|

15.1.

|

Assemble the lever arm with the

EN-6086-8

joint (1) and the

EN-6086-11

removable head (2).

|

Note

|

|

Removal head must point toward the intake side.

|

|

|

|

15.2.

|

Slide assembly on installation shaft over the 1st cylinder.

|

|

16.

|

Remove the intake valve springs, 1st cylinder.

|

Note

|

|

Removal head must be positioned vertically over the valve stem.

|

|

|

|

16.1.

|

Carefully push the valve springs down using the

EN-6086-7

lever arm.

|

Note

|

|

Observe the correct assignment.

|

|

|

|

16.2.

|

Remove the valve keepers.

|

|

|

16.3.

|

Remove the valve head and the valve springs.

|

|

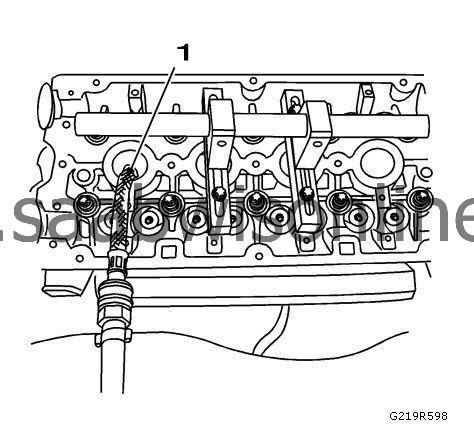

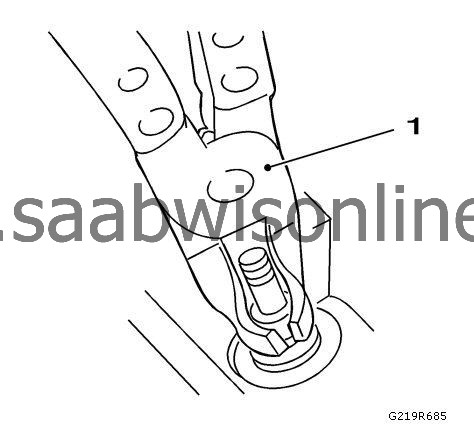

17.

|

Remove the valve stem seals with the

EN-840

puller (1).

|

|

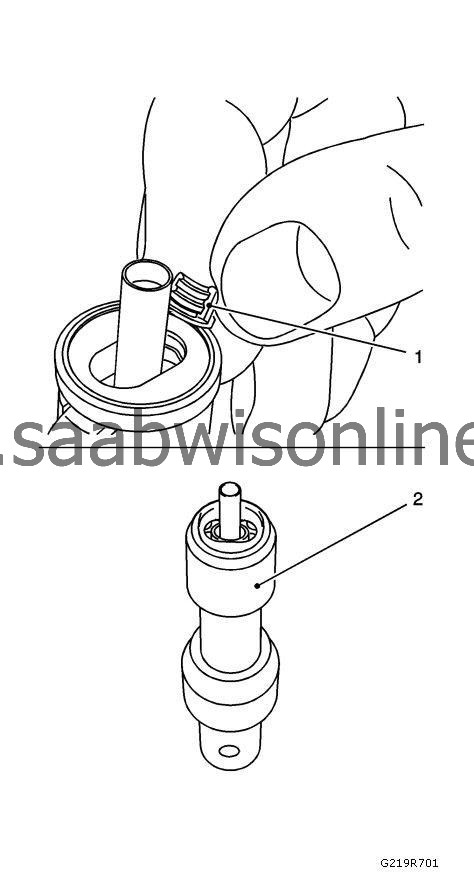

18.

|

Install the valve stem seals.

|

|

|

18.1.

|

Coat the valve stem with engine oil.

|

|

|

18.2.

|

Connect the new valve stem seals onto valve stem.

|

|

|

18.3.

|

Using the

EN-958

installer , drive home to limit stop.

|

|

19.

|

|

Note

|

|

Follow manufacturer instructions.

|

|

|

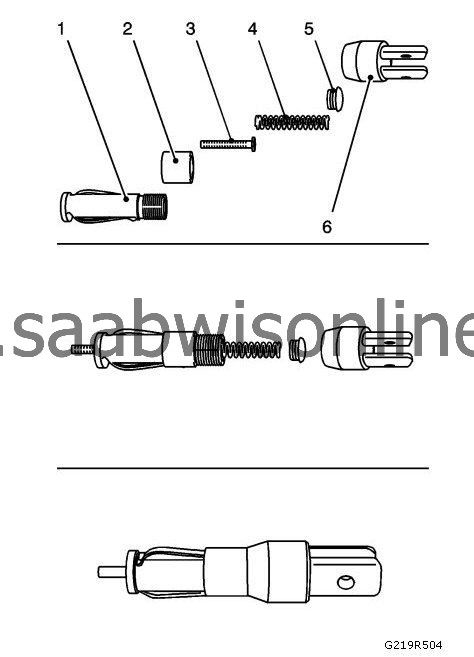

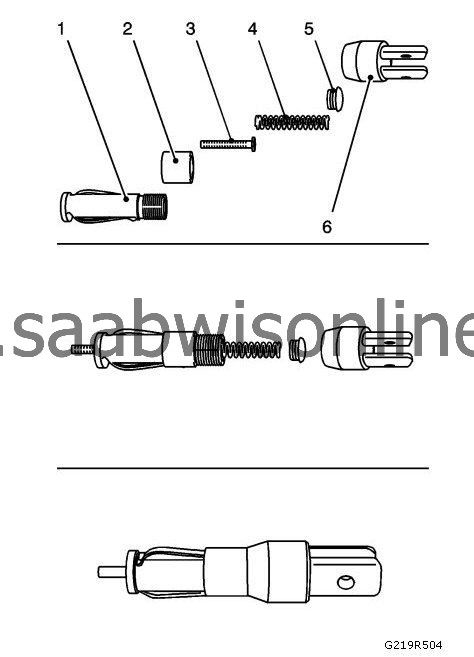

20.

|

Complete the

EN-6086-200-1

assembly head.

|

|

|

•

|

Use the

EN-6086-200-10

thrust piece.

|

|

|

•

|

Put together the assembly head consisting of mount (1), fixing sleeve (2), thrust piece (3), spring (4), screw fixing (5) and lever mount (6).

|

|

21.

|

Install the intake valve springs, 1st cylinder.

|

|

|

•

|

Insert the valve springs and valve head.

|

Note

|

|

Insert the valve cotters with the tapered end toward the valve.

|

|

|

|

•

|

Insert the valve cotters (1) in the

EN-6086-200-1

assembly head.

|

|

|

-

|

Slide the plastic clamping sleeve (2) in the direction of the lever arm mount.

|

|

|

-

|

Push the plastic clamping sleeve toward the valve.

|

Note

|

|

Assembly head must stand vertically above the valve stem. Valve cotters must engage audibly.

|

|

|

|

•

|

Attach the assembly head to the lever arm.

|

|

|

•

|

Carefully push the valve spring down using the

EN-6086-7

lever arm.

|

Note

|

|

Do not make 2nd attempt without inspecting that both valve cotters are seated in the assembly head.

|

|

|

22.

|

Inspect installation position.

|

|

23.

|

Inspect seating of the valve keepers (visual inspection).

|

|

24.

|

Transfer the

EN-6086-7

lever arm.

|

|

|

24.1.

|

Remove the lever arm.

|

|

|

24.2.

|

Detach the assembly head.

|

Note

|

|

Removal head must point toward the exhaust side.

|

|

|

|

24.3.

|

Attach the removal head.

|

|

|

24.4.

|

Install the lever arm.

|

|

25.

|

Remove the exhaust valve springs, 1st cylinder.

|

|

|

25.1.

|

Carefully push the valve springs down using the

EN-889-12

lever arm.

|

Note

|

|

Removal head must be positioned vertically over the valve stem.

|

|

|

|

25.2.

|

Remove the valve keepers

|

Note

|

|

Observe the correct assignment.

|

|

|

|

25.3.

|

Remove the valve head and the valve springs.

|

|

26.

|

Replace the valve stem seals.

|

|

|

26.1.

|

Pull off using the

EN-840

remover.

|

|

|

26.2.

|

Coat the valve stem with engine oil.

|

|

|

26.3.

|

Connect the new valve stem seals onto the valve stem.

|

|

|

26.4.

|

Using the

EN-958

installer , drive home to limit stop.

|

|

27.

|

Attach the

EN-6086-7

lever arm.

|

|

|

•

|

Insert the valve springs and valve head.

|

|

|

•

|

Insert the valve wedges in the

EN-889-2

assembly head.

|

Note

|

|

Insert the valve cotters with the tapered end toward the valve.

|

|

|

|

-

|

Push the plastic clamping sleeve toward the lever arm mounting.

|

|

|

-

|

Push the plastic clamping sleeve toward the valve.

|

Note

|

|

Assembly head must stand vertically above the valve stem. Valve cotters must engage audibly.

|

|

|

|

•

|

Attach the assembly head to the lever arm.

|

Note

|

|

Do not make 2nd attempt without inspecting that both valve cotters are seated in the assembly head.

|

|

|

|

•

|

Carefully push the valve spring down using the

EN-889-12

lever arm.

|

|

28.

|

Inspect installation position.

|

|

29.

|

Inspect seating of the valve keepers (visual inspection).

|

|

30.

|

Transfer the

EN-6086-15

pneumatic adapter.

|

|

|

30.1.

|

Interrupt the compressed air feed.

|

|

|

30.2.

|

Remove the adapter from cylinder number 1.

|

|

|

30.3.

|

Install the adapter to cylinder number 4.

|

|

|

30.4.

|

Apply compressed air to cylinder number 4.

|

|

31.

|

Replace the valve stem seal of cylinder 4 by analogy with step 14 to step 23.

|

|

32.

|

Remove the

EN-6086-15

pneumatic adapter.

|

|

|

32.1.

|

Interrupt the compressed air feed.

|

|

|

32.2.

|

Remove the adapter from cylinder number 4.

|

|

33.

|

Raise the vehicle by its full height.

|

|

34.

|

Remove the

EN 6625

holder.

|

|

35.

|

Set the crankshaft to ignition TDC of cylinder 3.

|

Note

|

|

Alignment marking on toothed belt drive wheel must align with marking on rear toothed belt cover.

|

|

|

36.

|

Turn crankshaft evenly by 180 degrees.

|

|

37.

|

Block the crankshaft.

|

|

38.

|

Install

EN-6625

holder to the engine block.

|

|

39.

|

Lower the vehicle by its full height

|

|

40.

|

Replace the valve stem seal of cylinders 2 and 3 by analogy with step 7 to step 23.

|

|

41.

|

Remove the

EN-6086-15

pneumatic adapter.

|

|

|

41.1.

|

Interrupt the compressed air feed.

|

|

|

41.2.

|

Remove the adapter from cylinder number 3.

|

|

42.

|

Remove the

EN-6086

automatic valve spring lever.

|

|

|

42.1.

|

Release the installation shaft.

|

|

|

42.2.

|

Remove both supports with the installation shaft.

|

|

|

42.3.

|

Remove the installation head from the lever arm.

|

|

2.

|

Remove

EN-6625

holder from the engine block.

|

|

|

•

|

Detach the screwed connection.

|

|

|

•

|

Tighten the bolted connection.

|

|

3.

|

Set the engine to 60 degrees (measurement l) before TDC.

|

|

4.

|

Set the crankshaft in direction of engine rotation to 60 degrees (measurement l) before TDC.

|