INSTALLATION

| INSTALLATION |

| AUTOMATIC BELT TENSION ADJUSTER ASSEMBLY AND BELT IDLER |

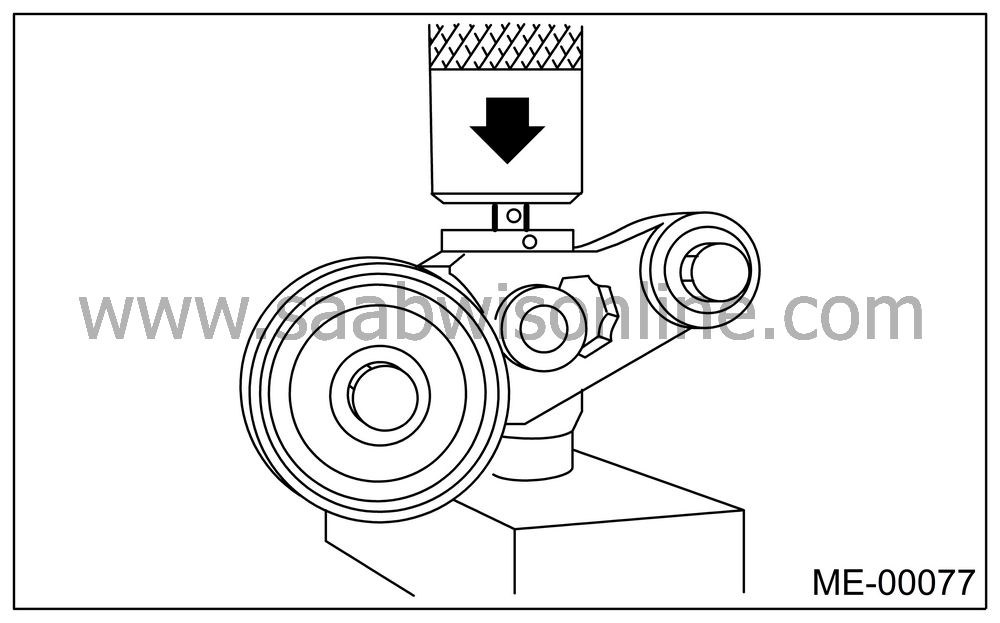

Preparation for installation of automatic belt tension adjuster assembly:

| Important | ||

| • |

Always use a vertical type pressing

tool to move the adjuster rod down.

|

|

| • |

Do not use a lateral type vise.

|

|

| • |

Push the adjuster rod vertically.

|

|

| • |

Be sure to slowly move the adjuster rod down applying

a pressure of 294 N (30 kgf, 66 lb) or more.

|

|

| • |

Press-in the push adjuster rod gradually taking more

than 3 minutes.

|

|

| • |

Do not allow press pressure to exceed 9,807 N (1,000

kgf, 2,205 lb).

|

|

| • |

Press the adjuster rod as far as the end surface of

cylinder. Do not press the adjuster rod into the cylinder. Doing

so may damage the cylinder.

|

|

| • |

Do not release the press pressure until stopper pin

is completely inserted.

|

|

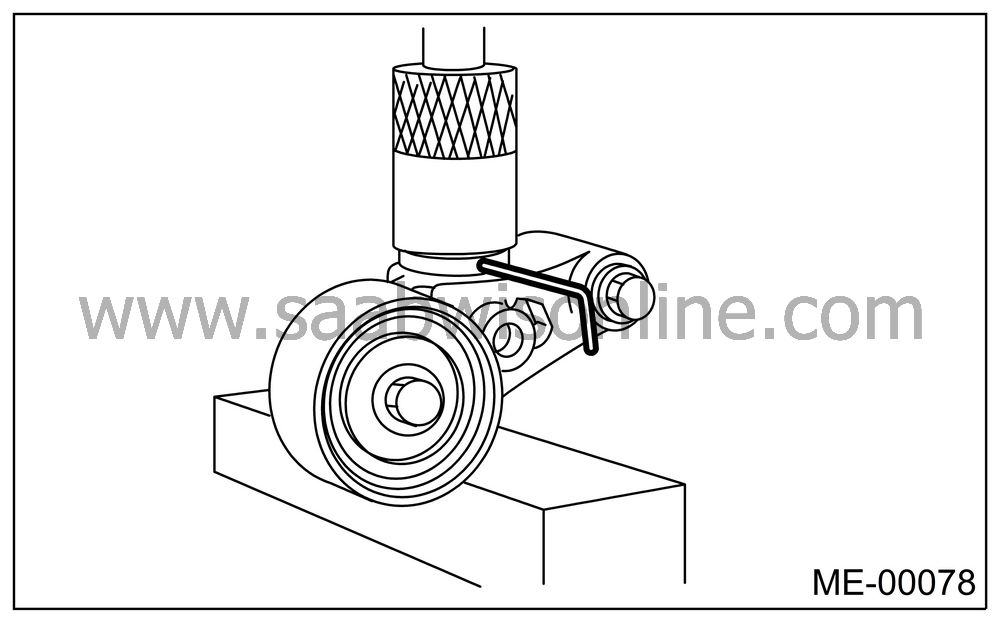

Attach the automatic belt tension adjuster assembly to the vertical pressing tool.

Slowly move the adjuster rod down with a pressure of 294 N (30 kgf, 66 lb) or more until the adjuster rod is aligned with the stopper pin hole in the cylinder.

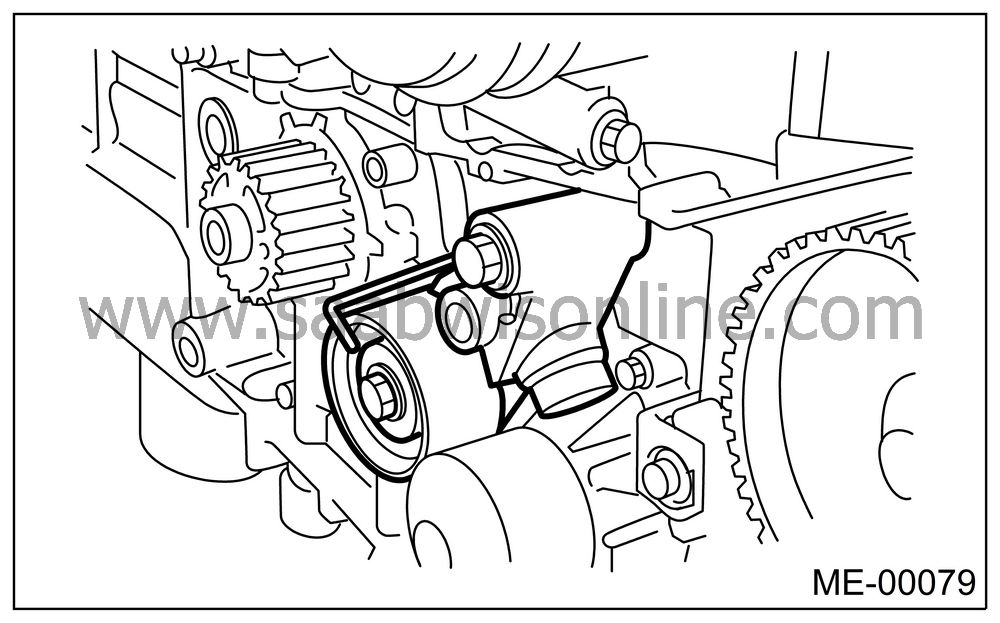

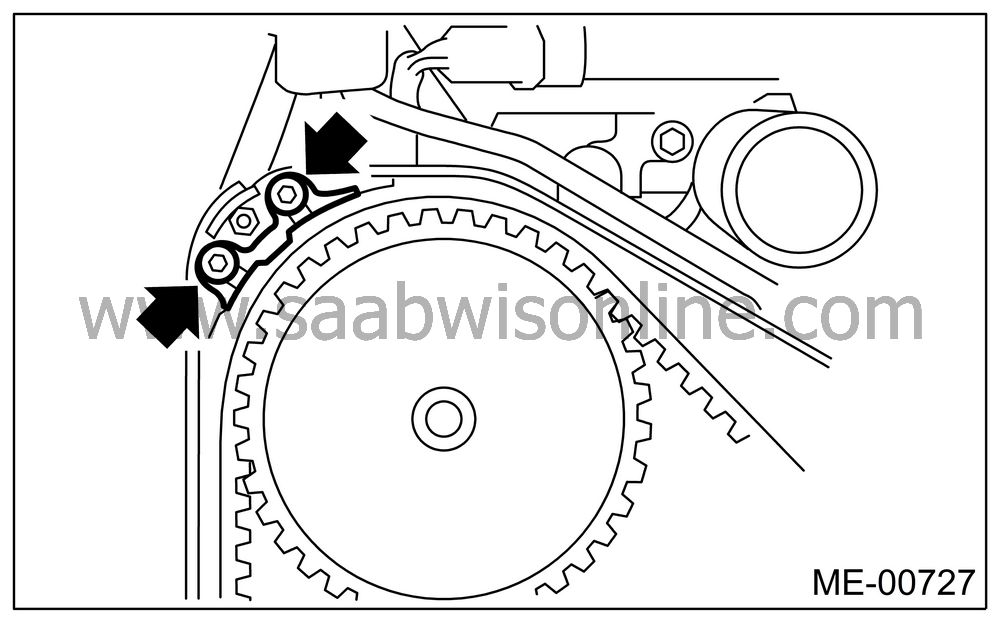

Install the automatic belt tension adjuster assembly.

Tightening torque:

39 Nm (4.0 kgf-m, 28.9 ft-lb)

Install the belt idler No. 2.

Tightening torque:

39 Nm (4.0 kgf-m, 28.9 ft-lb)

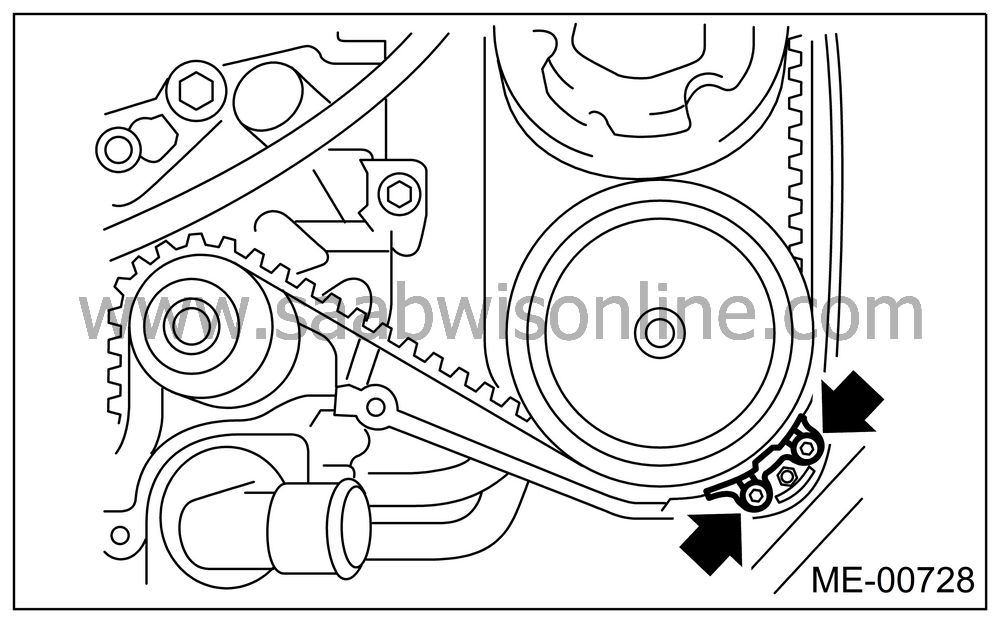

Install the belt idler.

Tightening torque:

39 Nm (4.0 kgf-m, 28.9 ft-lb)

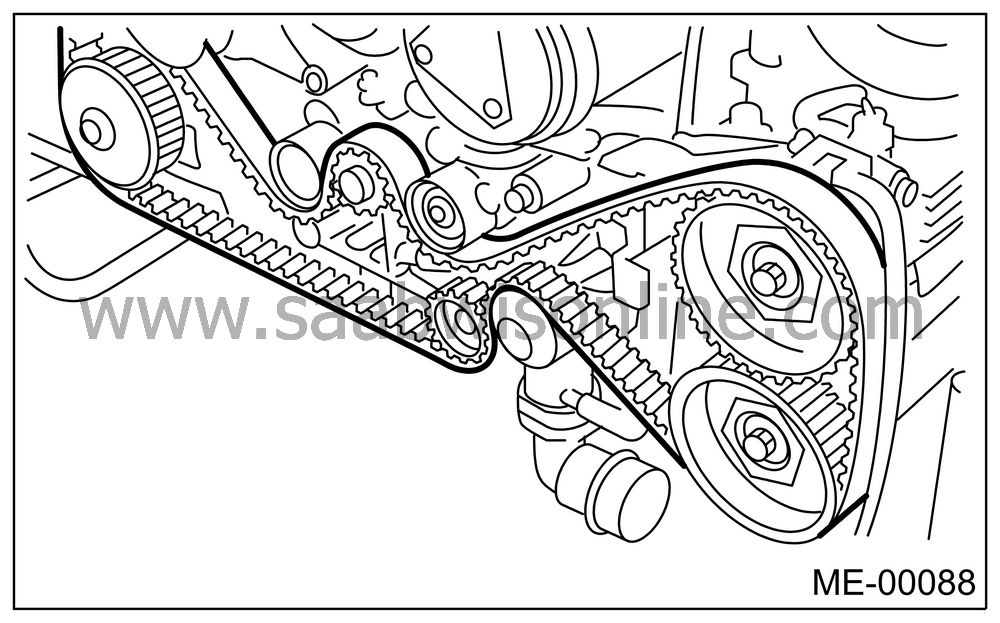

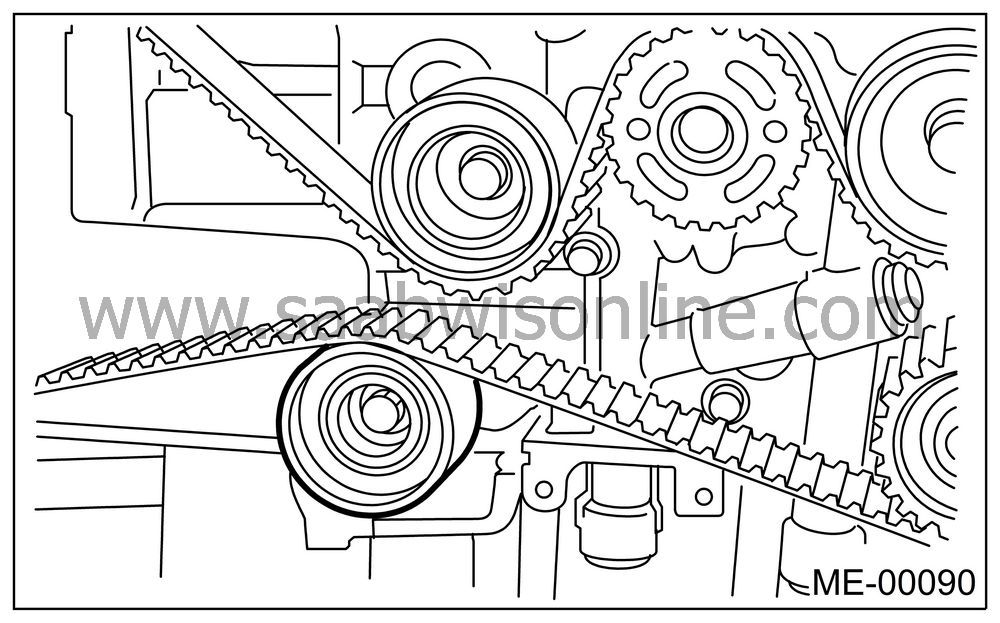

| TIMING BELT |

Preparation for installation of automatic belt tension adjuster assembly.

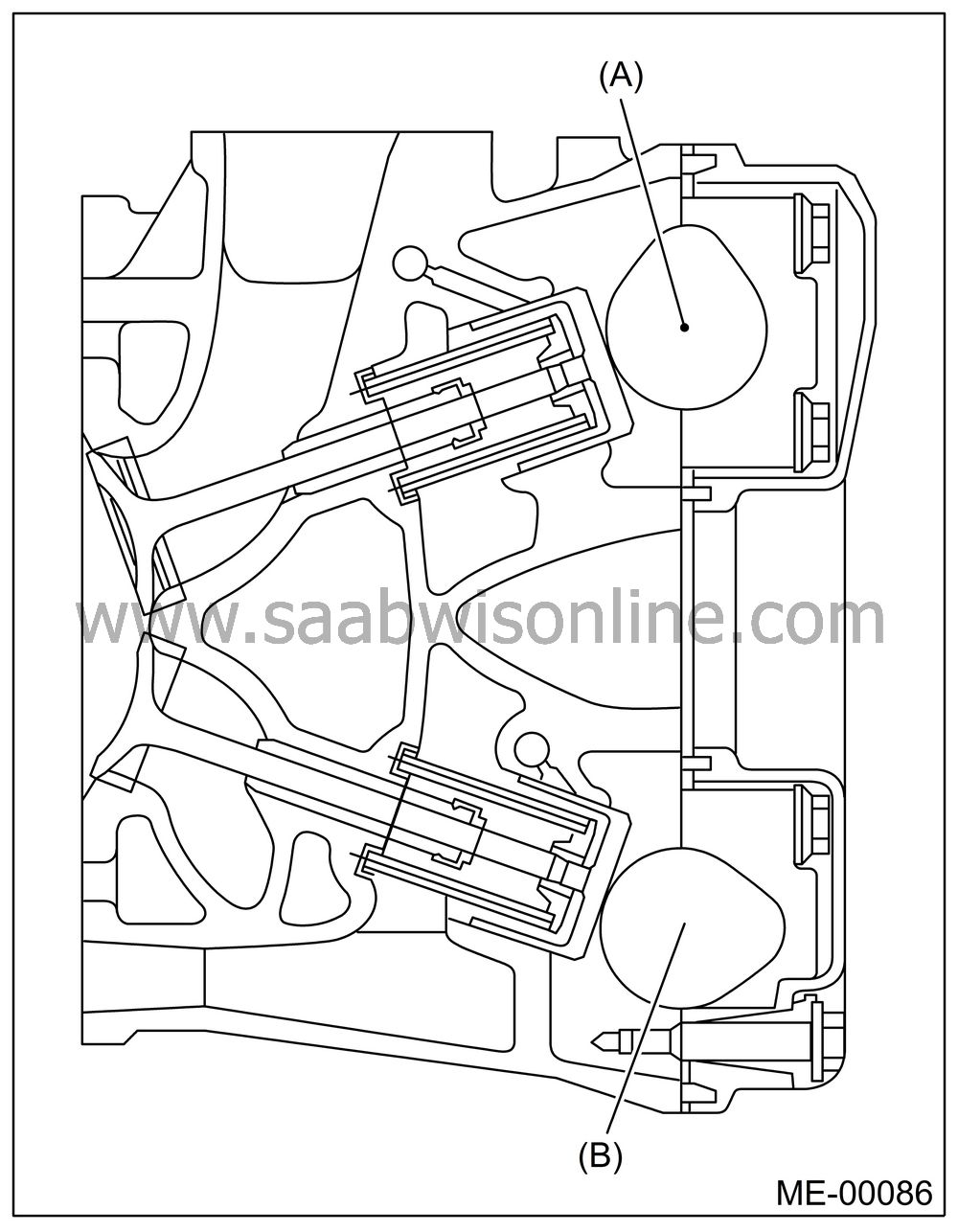

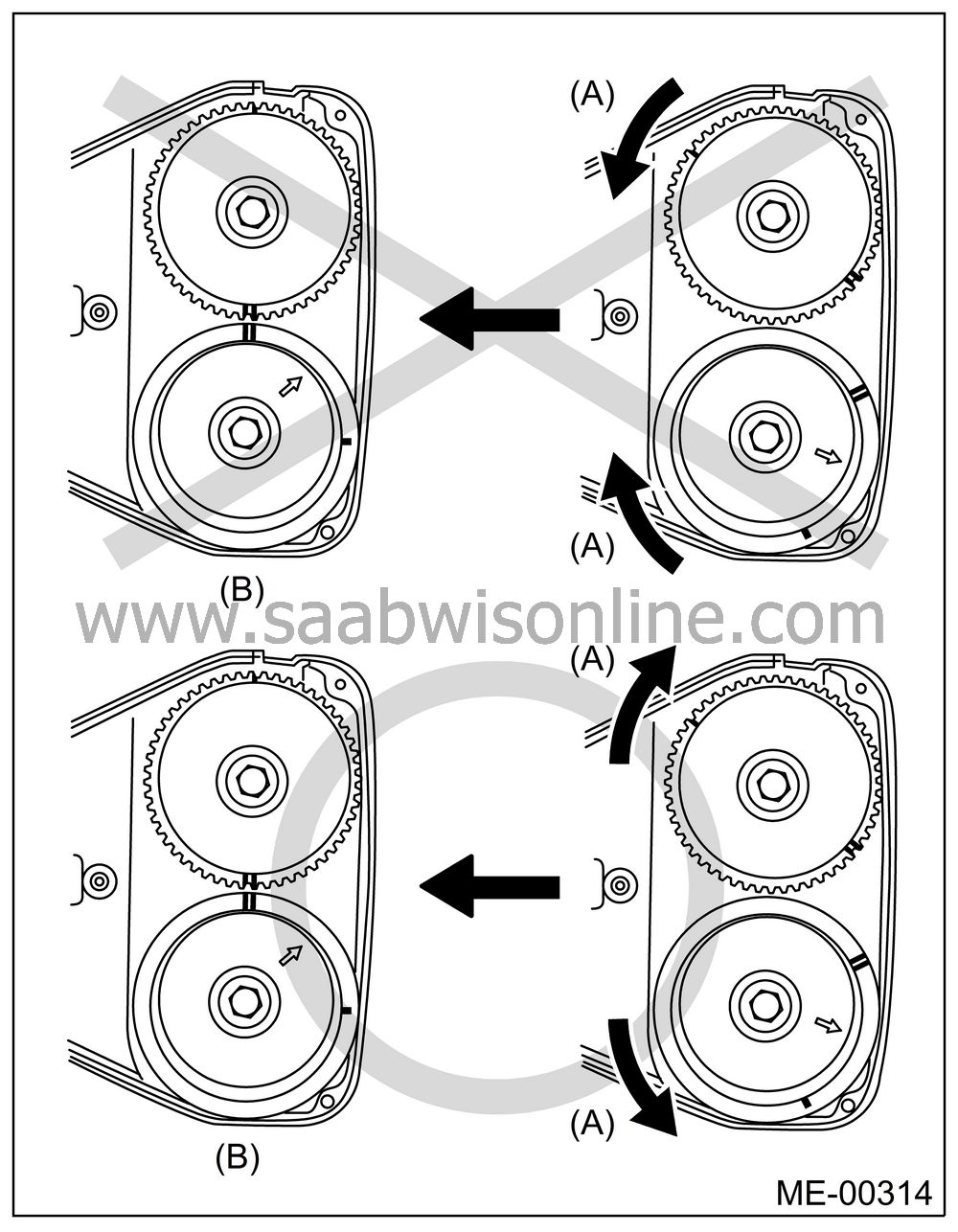

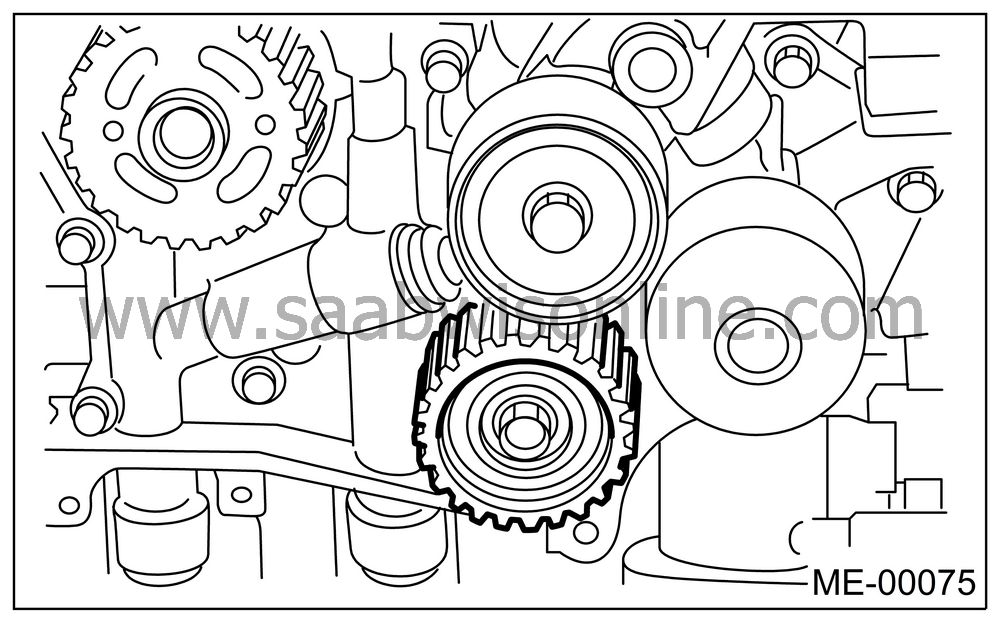

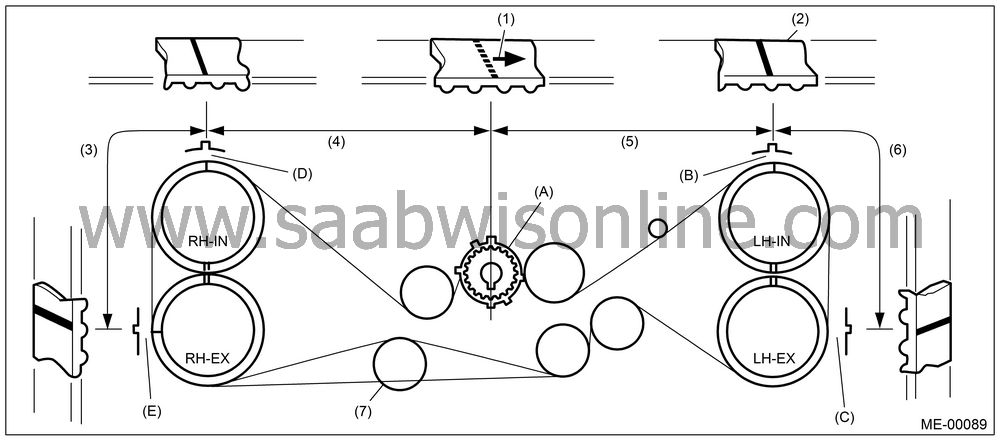

Crankshaft and cam sprocket alignment.

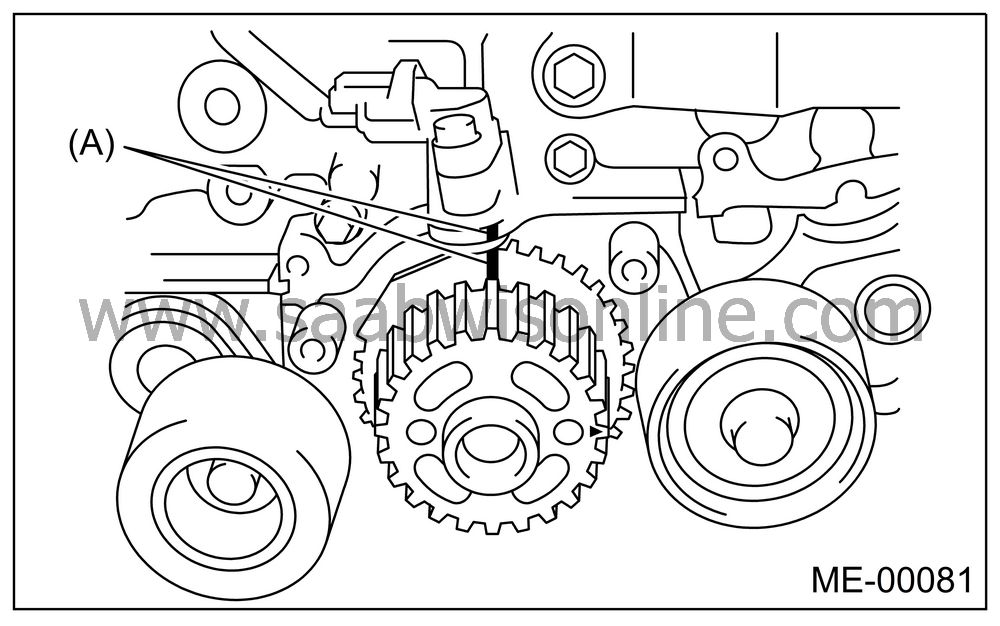

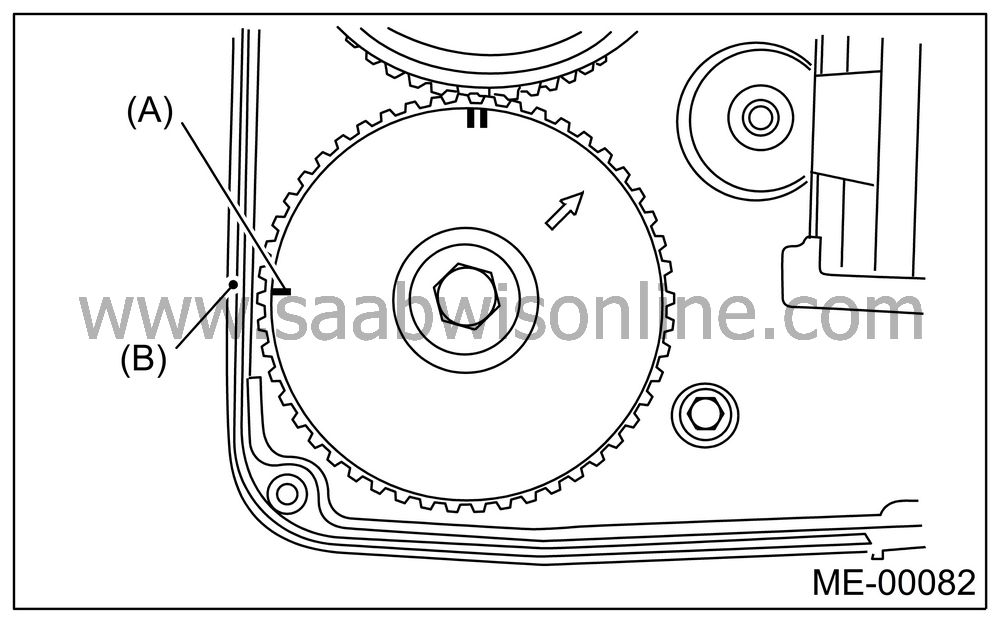

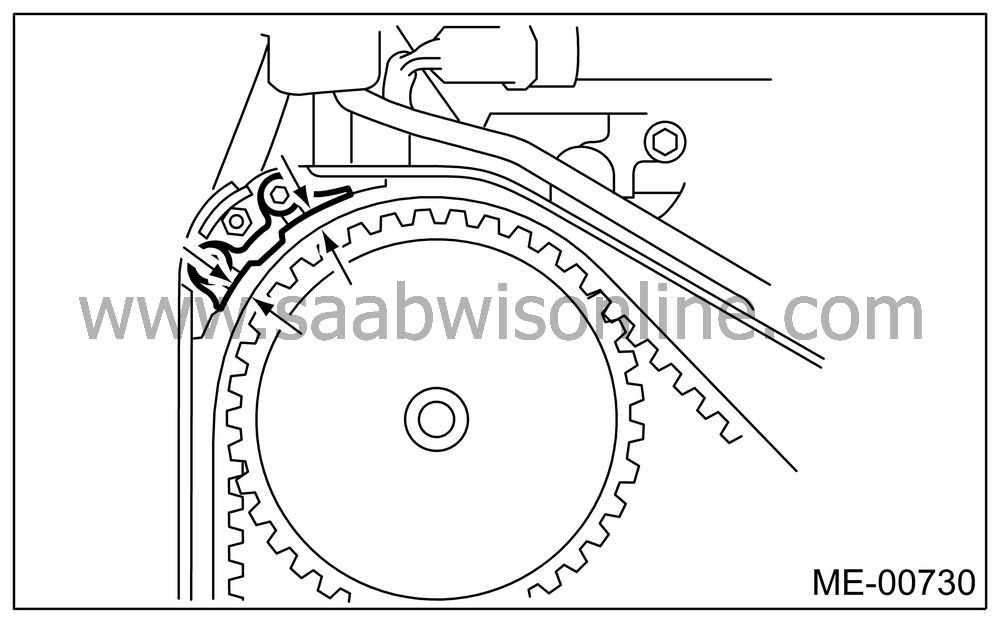

Align mark (A) on the crank sprocket with mark on the oil pump cover at cylinder block.

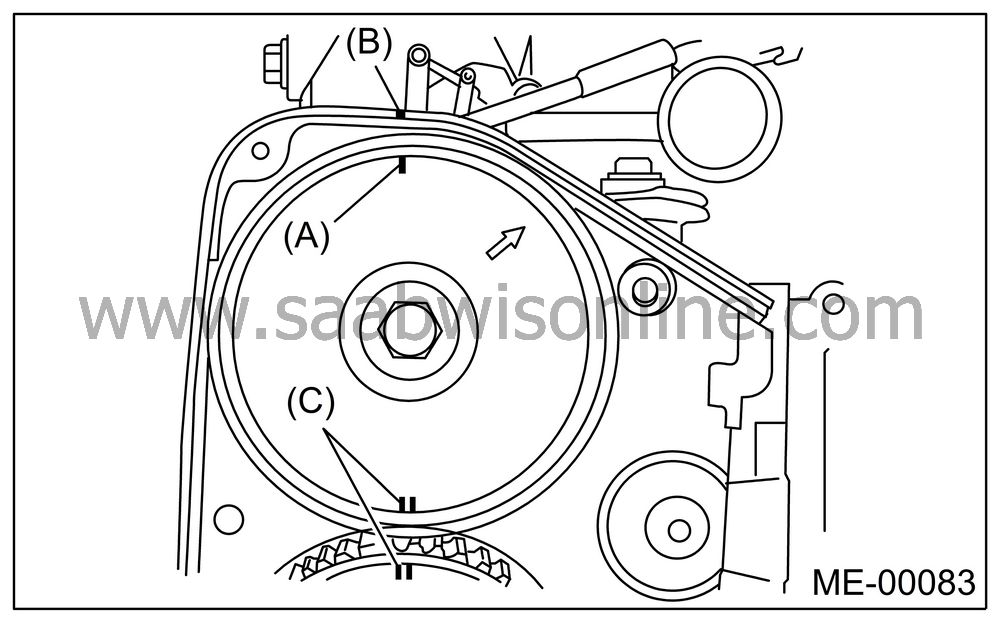

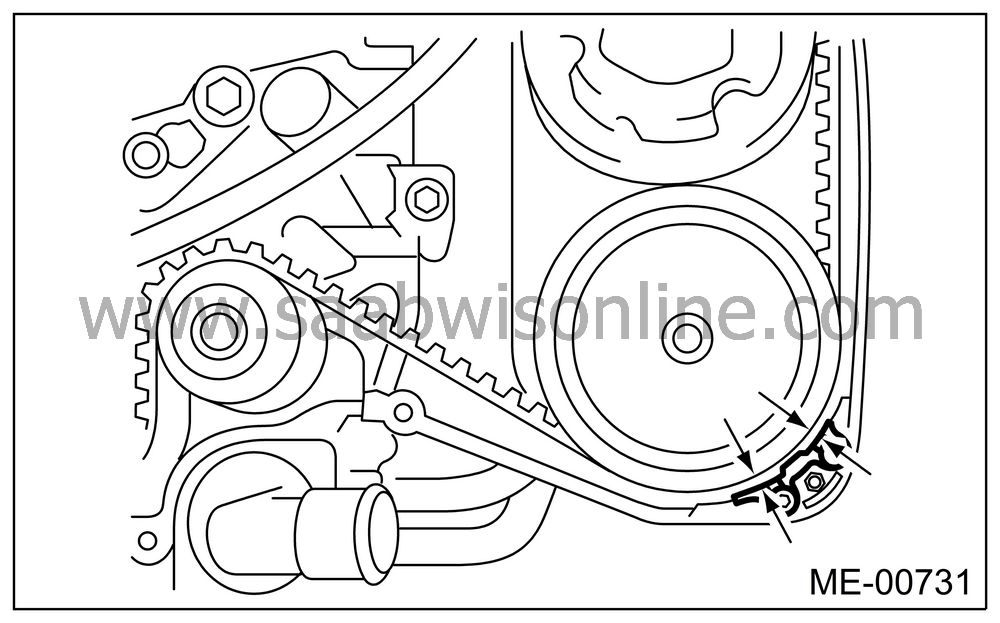

Align single line mark (A) on the exhaust cam sprocket (RH) with notch (B) on timing belt cover.

Align single line mark (A) on the intake cam sprocket (RH) with notch (B) on timing belt cover.

(Make sure double lines (C) on intake camshaft and exhaust cam sprockets are aligned.)

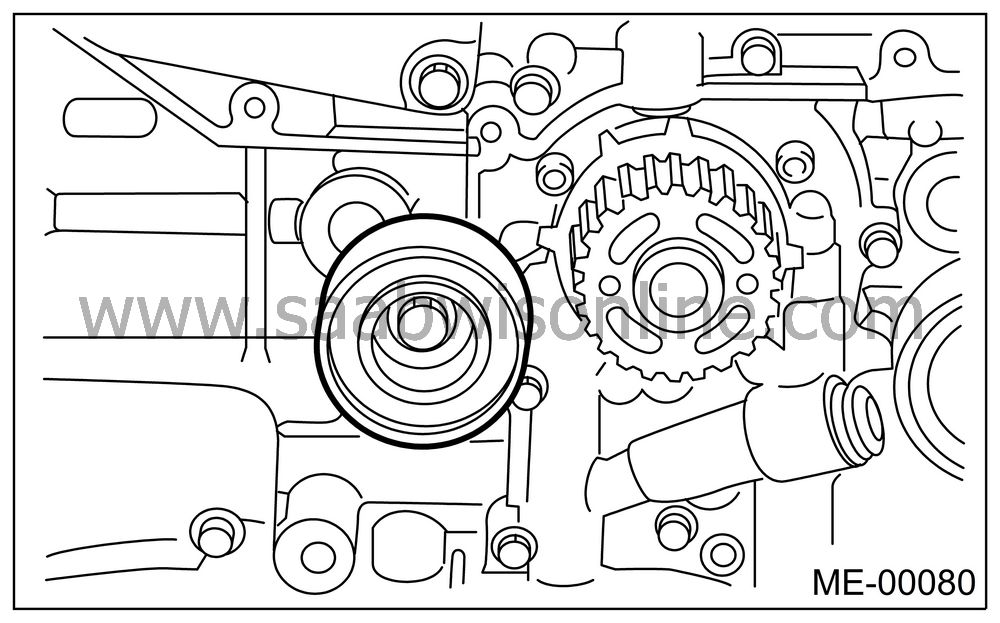

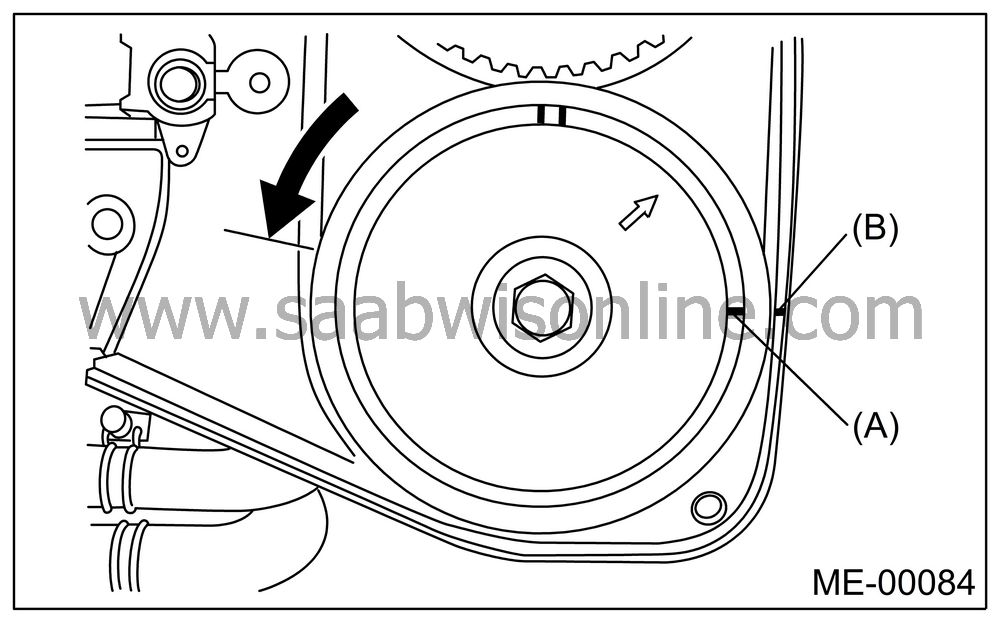

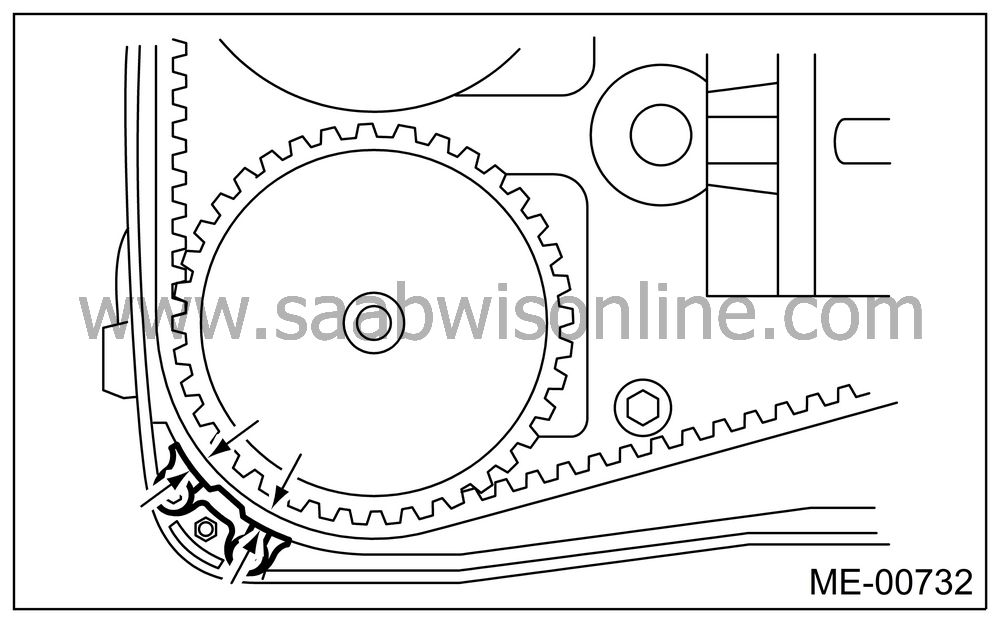

Align single line mark (A) on exhaust cam sprocket (LH) with notch (B) on timing belt cover by turning the sprocket counterclockwise (as viewed from front of engine).

Align the single line mark (A) on intake cam sprocket (LH) with notch (B) on timing belt cover by turning the sprocket clockwise (as viewed from front of engine).

Ensure the double lines (C) on intake and exhaust cam sprockets are aligned.

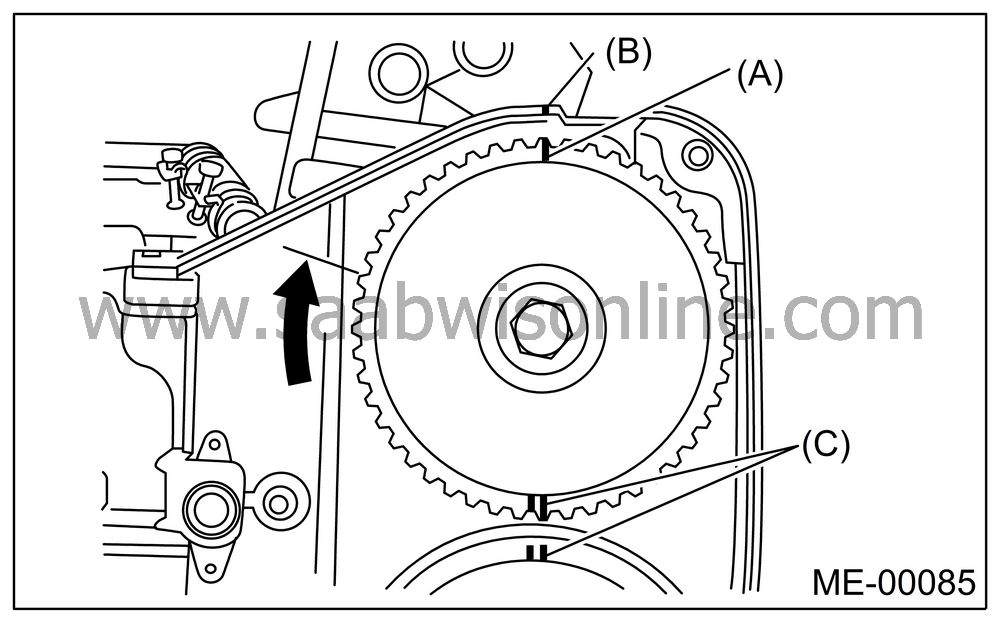

Ensure the camshaft and crank sprockets are positioned properly.

Installation of timing belt:

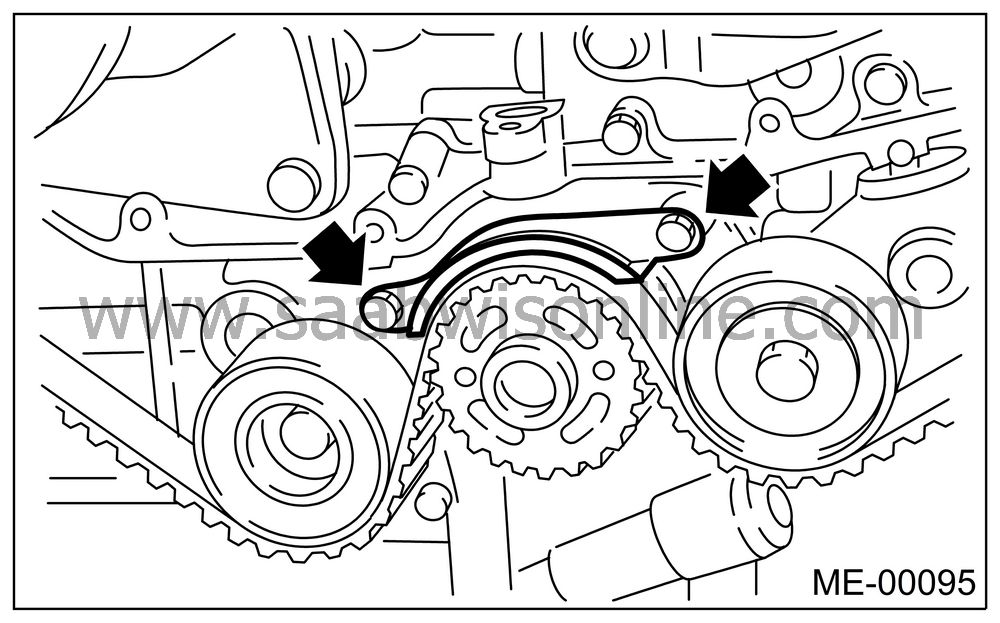

Align the alignment mark on timing belt with marks on sprockets in alphabetical order shown in the figure. While aligning marks, position the timing belt properly.

| Important | ||||||||||||||||||||

| • |

Disengagement of more than three

timing belt teeth may result in interference between the valve and

piston.

|

|||||||||||||||||||

| • |

Ensure the belt’s rotating direction is correct.

|

|||||||||||||||||||

Install the belt idlers.

Tightening torque:

39 Nm (4.0 kgf-m, 28.9 ft-lb)

| Note | ||

|

Make sure that the marks on the timing belt and sprockets are aligned. |

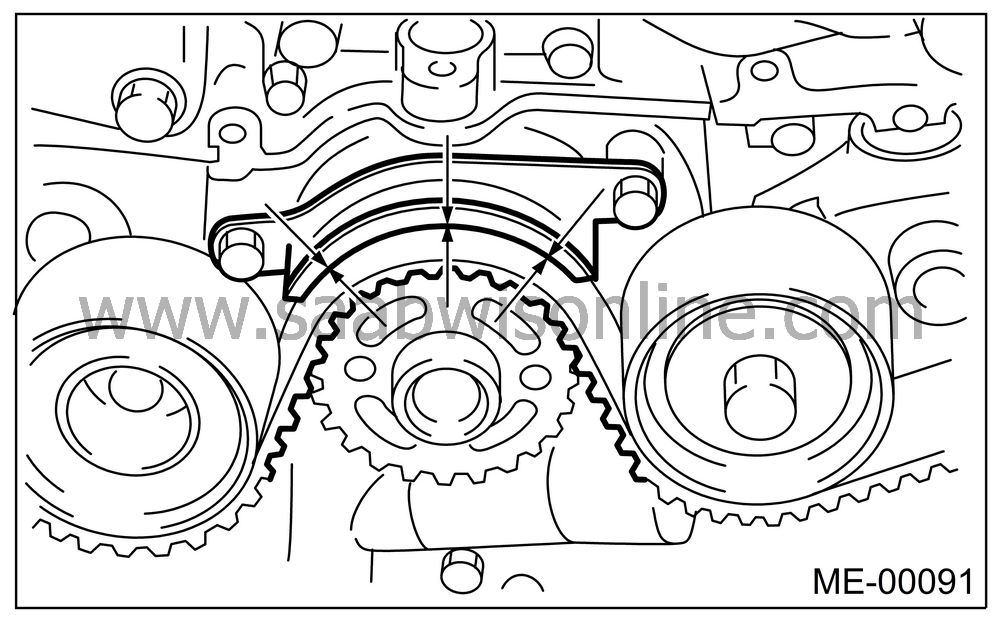

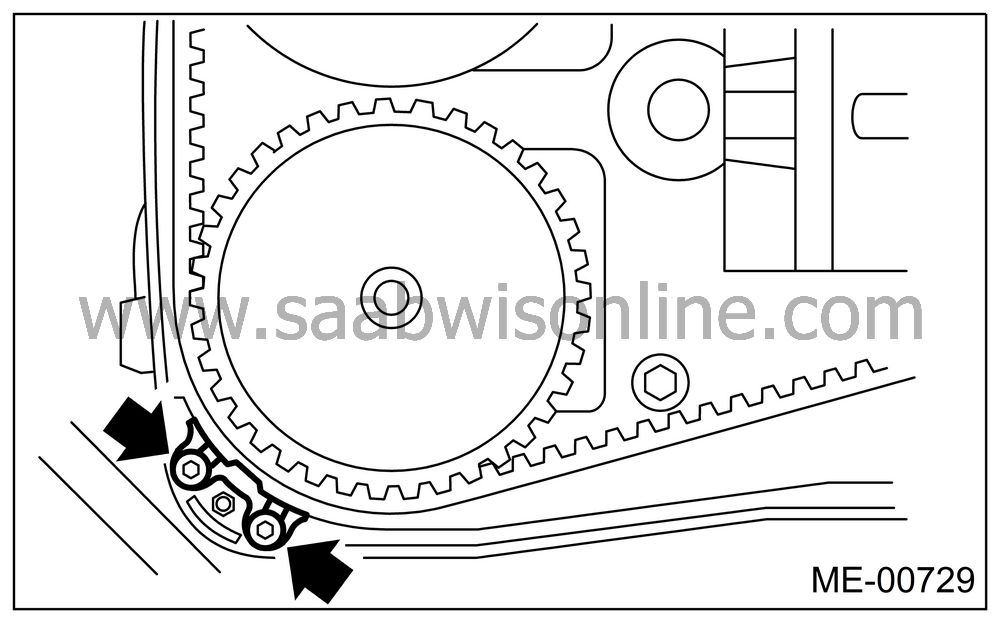

After ensuring that the marks on the timing belt and sprockets are aligned, remove the stopper pin from tensioner adjuster.

Install the timing belt guide. (MT model)

Temporarily tighten the bolts.

Check and adjust the clearance between timing belt and timing belt guide.

Clearance:

1.0±0.5 mm (0.039±0.020 in)

Tighten the bolts.

Tightening torque:

10 Nm (1.0 kgf-m, 7.2 ft-lb)

Tightening torque:

6.4 Nm (0.7 kgf-m, 5.1 ft-lb)

Tightening torque:

6.4 Nm (0.7 kgf-m, 5.1 ft-lb)

Tightening torque:

6.4 Nm (0.7 kgf-m, 5.1 ft-lb)

Install the timing belt cover.

Install the crank pulley.

Install the V-belt.