Front End Upper Tie Bar Support Replacement (Complete)

| Front End Upper Tie Bar Support Replacement (Complete) |

| Removal Procedure |

Refer to Approved Equipment for Collision Repair Warning .

Refer to Glass and Sheet Metal Handling Warning .

| 1. |

Disable the SIR system. Refer to

SIR Disabling and Enabling

.

|

|

| 2. |

Disconnect the negative battery cable. Refer to

Battery Negative Cable Disconnection and Connection

.

|

|

| 3. |

Repair as much of the damaged area as possible. Refer to

Dimensions - Body

.

|

|

| 4. |

Remove all related panels and components.

|

|

| 5. |

Remove the front end upper tie bar. Refer to

Front End Upper Tie Bar Replacement

.

|

|

| 6. |

Remove the headlamp. Refer to

Headlamp Replacement

.

|

|

| 7. |

Remove the headlamp mount panel. Refer to

Headlamp Mount Panel Replacement

.

|

|

| 8. |

Remove the front wheelhouse panel reinforcement.

Front Wheelhouse Panel Reinforcement Replacement

|

|

| 9. |

Remove the sealers and anti-corrosion materials from the repair area, as necessary. Refer to

Anti-Corrosion Treatment and Repair (Base)

Anti-Corrosion Treatment and Repair (Corrosion Protection)

.

|

|

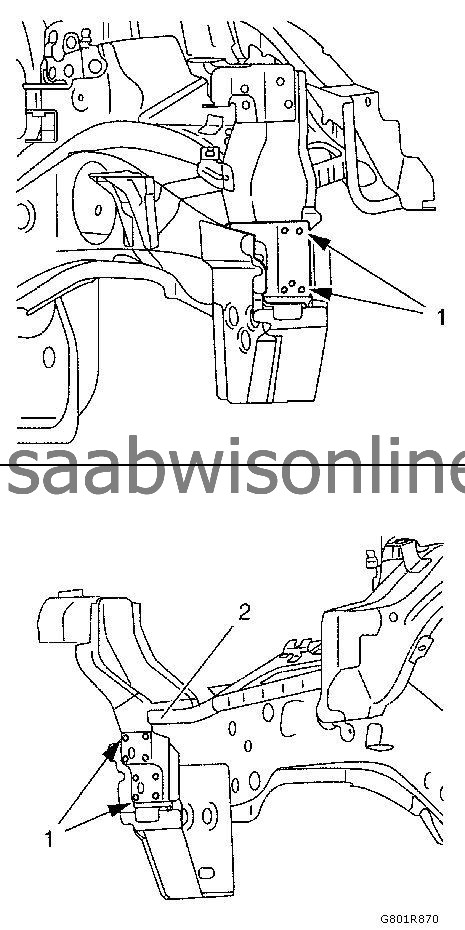

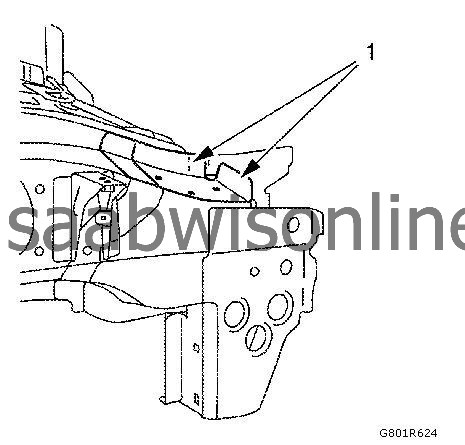

| 10. |

Locate and drill out all of the necessary factory welds.

|

|||||||

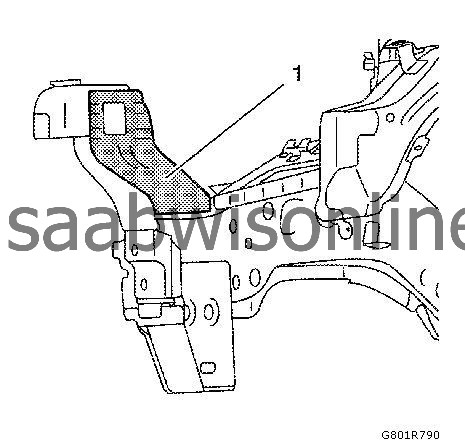

| 11. |

Remove the front end sheet metal cross panel reinforcement (1).

|

|

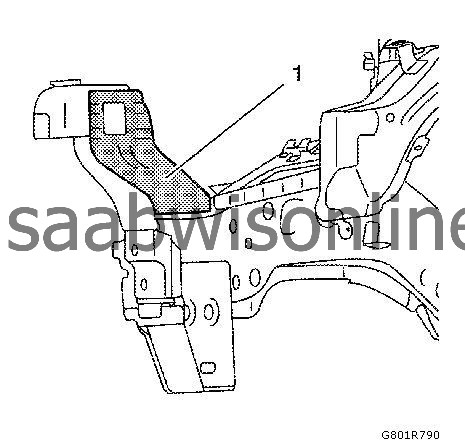

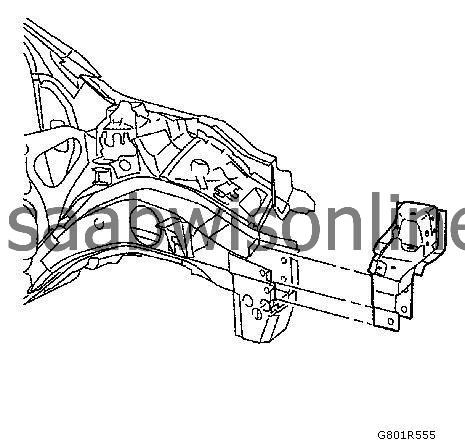

| 13. |

Remove the structural adhesive (2).

|

|

| 14. |

Locate and drill out all of the necessary factory welds (1).

|

|||||||

| 15. |

Remove the front end upper tie bar support.

|

|

| Installation Procedure |

| 1. |

Clean and prepare the attaching surfaces for welding.

|

|

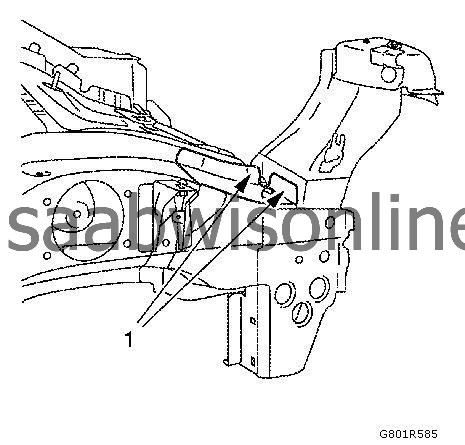

| 2. |

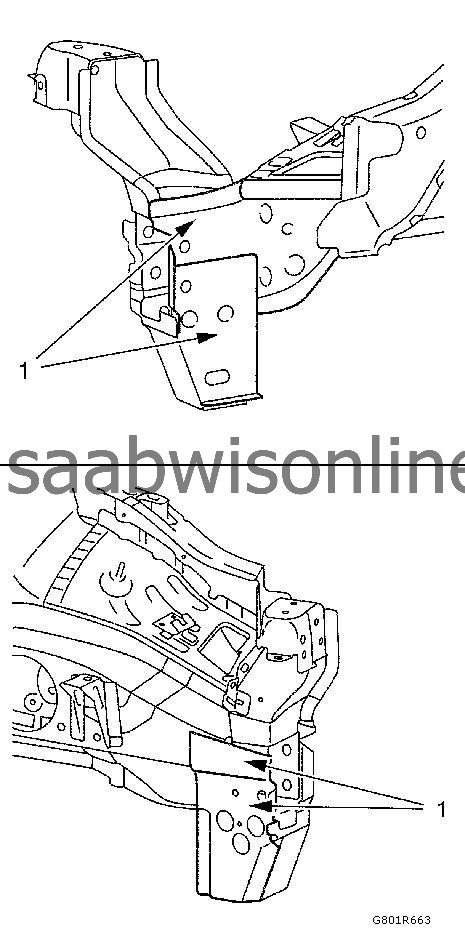

Apply bodywork repair through structural adhesive to body (1). Refer to

Structural Adhesive Body Repairs

.

|

|

| 3. |

Clean and prepare the attaching surfaces for welding.

3x slots 8x24 mm (0.3x0.9 in)

|

|

| 4. |

Position the front end upper tie bar support on the vehicle.

|

|

| 5. |

Verify the fit of the front end upper tie bar support.

|

|

| 6. |

Clamp the front end upper tie bar support into position.

|

|

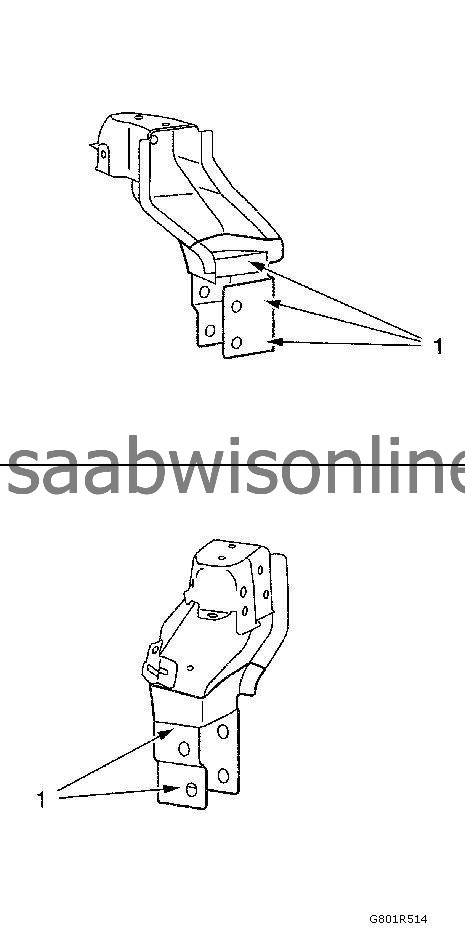

| 7. |

Spot weld (1) the front end upper tie bar support accordingly.

|

|||||||

| 8. |

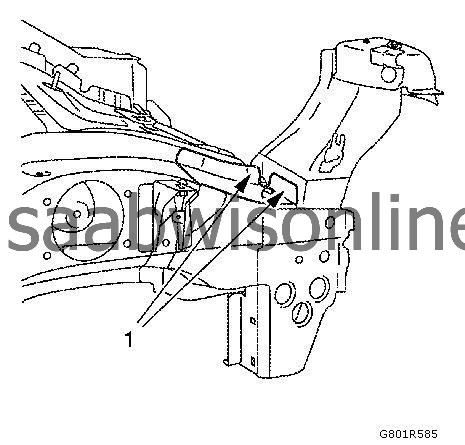

MIG-braze (1) the front end upper tie bar support.

|

|

| 9. |

Grind MIG brazed seams.

|

|

| 10. |

Position the front end sheet metal cross panel reinforcement (1) on the vehicle.

|

|||||||

| 11. |

Verify the fit of the front end sheet metal cross panel reinforcement (1).

|

|

| 12. |

Clamp the front end sheet metal cross panel reinforcement (1) into position.

|

|

| 13. |

Spot weld the front end sheet metal cross panel reinforcement (1) accordingly.

|

|

| 14. |

Apply the sealers and anti-corrosion materials to the repair area, as necessary. Refer to

Anti-Corrosion Treatment and Repair (Base)

Anti-Corrosion Treatment and Repair (Corrosion Protection)

.

|

|

| 15. |

Install all related panels and components.

|

|

| 16. |

Install the front wheelhouse panel reinforcement.

Front Wheelhouse Panel Reinforcement Replacement

|

|

| 17. |

Install the headlamp mount panel. Refer to

Headlamp Mount Panel Replacement

.

|

|

| 18. |

Install the front end upper tie bar. Refer to

Front End Upper Tie Bar Replacement

.

|

|

| 19. |

Install the headlamp. Refer to

Headlamp Replacement

.

|

|

| 20. |

Connect the negative battery cable. Refer to

Battery Negative Cable Disconnection and Connection

.

|

|

| 21. |

Enable the SIR system. Refer to

SIR Disabling and Enabling

.

|

|